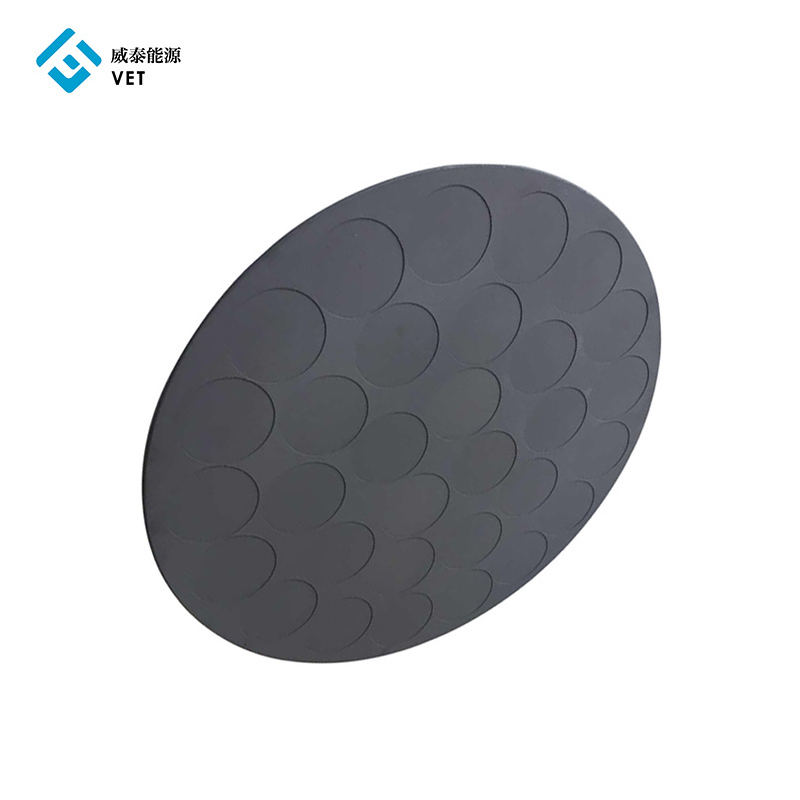

SiC yokutidwa ndi graphite chonyamulira ndi gawo lofunikira lomwe limagwiritsidwa ntchito popanga ma semiconductor osiyanasiyana. Timagwiritsa ntchito ukadaulo wathu wovomerezeka kuti tipange chonyamulira cha silicon carbide kukhala choyera kwambiri, chofananira bwino choyatira komanso moyo wabwino kwambiri wautumiki, komanso kukana kwamphamvu kwamankhwala komanso kukhazikika kwamafuta.

Zogulitsa zathu:

1. High kutentha makutidwe ndi okosijeni kukana mpaka 1700 ℃.

2. Kuyera kwakukulu ndi kufanana kwa kutentha

3. Kukana kwabwino kwa dzimbiri: asidi, alkali, mchere ndi organic reagents.

4. High kuuma, yaying'ono pamwamba, particles zabwino.

5. Moyo wautali wautumiki komanso wokhazikika

| CVD SiC薄膜基本物理性能 Zida zoyambira za CVD SiCzokutira | |

| 性质 / Katundu | 典型数值 / Mtengo Wofanana |

| 晶体结构 / Kapangidwe ka Crystal | FCC β gawo多晶,主要為(111)取向 |

| 密度 / Kuchulukana | 3.21g/cm³ |

| 硬度 / Kuuma | 2500 维氏硬度 (500g katundu) |

| 晶粒大小 / Mbewu SiZe | 2 ~ 10μm |

| 纯度 / Chemical Purity | 99.99995% |

| 热容 / Kutentha Kwambiri | 640 jkg-1·K-1 |

| 升华温度 / Sublimation Kutentha | 2700 ℃ |

| 抗弯强度 / Flexural Mphamvu | 415 MPa RT 4-mfundo |

| 杨氏模量 / Young's Modulus | 430 Gpa 4pt bend, 1300 ℃ |

| 导热系数 / ThermalConductivity | 300Wm-1·K-1 |

| 热膨胀系数 Kukula kwa Matenthedwe (CTE) | 4.5 × 10-6K-1 |

VET Energy ndi omwe amapanga makonda a graphite ndi silicon carbide okhala ndi zokutira zosiyanasiyana monga zokutira za SiC, zokutira za TaC, zokutira zagalasi za kaboni, zokutira kaboni za pyrolytic, ndi zina zambiri, zimatha kupereka magawo osiyanasiyana osinthika a semiconductor ndi mafakitale a photovoltaic.

Gulu lathu laukadaulo limachokera ku mabungwe apamwamba ofufuza zapakhomo, litha kukupatsirani mayankho aukadaulo.

Timapitirizabe kupanga njira zapamwamba zoperekera zipangizo zamakono, ndipo tapanga teknoloji yokhayo yovomerezeka, yomwe ingapangitse mgwirizano pakati pa zokutira ndi gawo lapansi kukhala lolimba komanso losavuta kusokoneza.

Takulandirani ndi manja awiri kuti mudzacheze fakitale yathu, tikambiranenso!

-

Graphite heater Silicon carbide (SiC) SiC coati ...

-

China Wopanga SiC yokutidwa Graphite MOCVD Ep...

-

Chotenthetsera cha Graphite Chokhazikika cha Semiconductor Si...

-

CVD SiC yokutidwa Carbon-carbon Composite CFC Boti...

-

CVD sic zokutira carbon-carbon composite nkhungu

-

CVD sic zokutira cc gulu ndodo, pakachitsulo carbi ...

-

Kutentha kwakukulu kukana cholimba Silicon ndodo ...

-

Mechanical Carbon Graphite Bush Rings,Silicone ...

-

Refractory Ceramic Bonded Silicon Carbide Sic C...

-

mafuta kukana SIC thrust kubala, Silicon kubala

-

SiC Coated Graphite Base Carriers