Nā waiwai o ka carbide silikona i hoʻopaʻa hou ʻia

ʻO ka carbide silicon recrystallized (R-SiC) he mea hana kiʻekiʻe me ka paʻakikī lua wale nō i ke daimana, i hana ʻia ma kahi wela kiʻekiʻe ma luna o 2000 ℃. Mālama ia i nā waiwai maikaʻi he nui o SiC, e like me ka ikaika wela kiʻekiʻe, ke kūpaʻa ʻana i ka corrosion ikaika, ke kūpaʻa oxidation maikaʻi loa, ke kūpaʻa haʻalulu maikaʻi a pēlā aku.

● ʻO nā mea mechanical maikaʻi loa. ʻO ka carbide silicon recrystallized he kiʻekiʻe aʻe ka ikaika a me ka ʻoʻoleʻa ma mua o ke kalapona kalapona, ke kūpaʻa hopena kiʻekiʻe, hiki ke pāʻani i ka hana maikaʻi i nā wahi wela wela, hiki ke pāʻani i ka hana counterbalance maikaʻi i nā ʻano kūlana. Eia kekahi, loaʻa iā ia ka maʻalahi maikaʻi a ʻaʻole maʻalahi i ka pōʻino e ka hoʻolōʻihi ʻana a me ke kulou ʻana, kahi e hoʻomaikaʻi nui ai i kāna hana.

● Kiʻekiʻe corrosion kū'ē. ʻO ka carbide silicon recrystallized he kiʻekiʻe ka corrosion kū'ē i nāʻano media likeʻole, hiki ke pale i ka erosion o nāʻano media corrosive, hiki ke mālama i kona mau mea mechanical no ka manawa lōʻihi, he paʻa ikaika, iʻoi aku ka lōʻihi o ke ola. Eia kekahi, loaʻa iā ia ka paʻa wela maikaʻi, hiki ke hoʻololi i kekahi ʻano o nā loli wela, hoʻomaikaʻi i kāna hopena noi.

● ʻAʻole e emi ka sintering. No ka emi ʻole o ke kaʻina hana sintering, ʻaʻohe koʻikoʻi koena e hoʻoneʻe i ka deformation a i ʻole ka haki ʻana o ka huahana, a hiki ke hoʻomākaukau ʻia nā ʻāpana me nā ʻano paʻakikī a me ka pololei kiʻekiʻe.

| 重结晶碳化硅物理特性 Nā waiwai kino o Recrystallized Silicon Carbide | |

| 性质 / Waiwai | 典型数值 / Waiwai maʻamau |

| 使用温度/ Mahana hana (°C) | 1600°C (me ka oxygen), 1700°C (hoemi kaiapuni) |

| SiC含量/ maʻiʻo SiC | > 99.96% |

| 自由Si含量/ Maikaʻi Si manuahi | < 0.1% |

| 体积密度/ʻAno nui | 2.60-2.70 g/cm3 |

| 气孔率/ ʻIke ʻia ka porosity | < 16% |

| 抗压强度/ Ka ikaika hoʻoemi | > 600MPa |

| 常温抗弯强度/Ka ikaika kulou anu | 80-90 MPa (20°C) |

| 高温抗弯强度Ka ikaika piko wela | 90-100 MPa (1400°C) |

| 热膨胀系数/ Hoʻonui wela @1500°C | 4.70 10-6/°C |

| 导热系数/ʻO ka wela wela @1200°C | 23W/m•K |

| 杨氏模量/ Modulus elastic | 240 GPa |

| 抗热震性/ Ke pale ʻana i ka haʻalulu wela | Maikaʻi loa |

ʻO VET Energy ka kamea hana maoli o ka graphite maʻamau a me nā huahana silicon carbide me ka uhi CVD,hiki ke hoolakoʻokoʻanā ʻāpana i hana ʻia no ka semiconductor a me ka ʻoihana photovoltaic. OʻO kāu hui ʻenehana mai nā keʻena noiʻi kūloko kiʻekiʻe, hiki ke hāʻawi i nā ʻoihana ʻoihana ʻoi aku ka nuināu.

Hoʻomau mau mākou i nā kaʻina hana kiʻekiʻe e hāʻawi i nā mea ʻoi aku ka holomua,aUa hana ʻo ia i kahi ʻenehana patented kūʻokoʻa, hiki iā ia ke hana i ka hoʻopaʻa ʻana ma waena o ka uhi a me ka substrate i ʻoi aku ka paʻa a emi ʻole i ka wehe.

| CVD SiC薄膜基本物理性能 Nā waiwai kino kumu o CVD SiCka uhi ʻana | |

| 性质 / Waiwai | 典型数值 / Waiwai maʻamau |

| 晶体结构 / Hoʻomoe Crystal | Māhele FCC β多晶,主要为(111)取向 |

| 密度 / Paʻa | 3.21 g/cm³ |

| 硬度 / Oolea | 2500 维氏硬度(500g load) |

| 晶粒大小 / ʻAiʻa palaoa | 2~10μm |

| 纯度 / Maemae Kemika | 99.99995% |

| 热容 / Hikina Wela | 640 J·kg-1·K-1 |

| 升华温度 / Kaumaha Sublimation | 2700 ℃ |

| 抗弯强度 / Ka Ikaika Pilikia | 415 MPa RT 4-point |

| 杨氏模量 / 'Ōpio's Modulus | 430 Gpa 4pt piko, 1300 ℃ |

| 导热系数 / ThermalʻO ka hoʻokō | 300W·m-1·K-1 |

| 热膨胀系数 / Hoʻonui wela (CTE) | 4.5×10-6K-1 |

Hoʻokipa maikaʻi iā ʻoe e kipa i kā mākou hale hana, e kūkākūkā hou kāua!

-

Maʻemaʻe kiʻekiʻe kiʻekiʻe ʻo SiC i uhi ʻia ʻo Graphite Heater H...

-

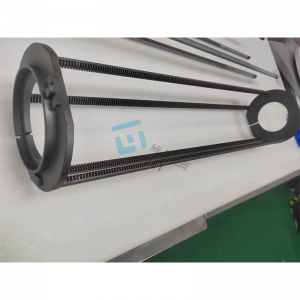

CVD Silicon Carbide Coated Graphite Ring

-

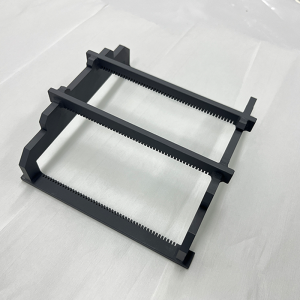

Pāpaʻi Hui Pū ʻIa-Kapona me ka uhi SiC

-

Nui Nui Recrystallized Silicon Carbide Wafer...

-

ʻO CVD SiC i uhi ʻia ʻo Carbon-carbon Composite CFC Boat...

-

ʻO ka waʻa kristal Silicon Carbide Recrystallized No...