Kuwana kuzadzikiswa kwemutengi ndicho chinangwa chekambani yedu pasina kupera. Isu tichaita nhanho dzinotyisa dzekuwana zvigadziriso zvitsva uye zvemhando yepamusoro, kusangana nezvako zvakasarudzika uye kukupa iwe pre-kutengesa, pa-kutengesa uye mushure-kutengesa vanopa veHot New Products Plasma Enhanced CVD Tube Furnace yeDeposition yePamusoro-. Quality Hard Films, Gamuchirai kubvunza kwako, yakanyanya kunaka sevhisi ichapihwa nemoyo uzere.

Kuwana kuzadzikiswa kwemutengi ndicho chinangwa chekambani yedu pasina kupera. Isu tichaita nhanho dzinotyisa dzekuwana mhinduro nyowani uye dzepamusoro-soro, kusangana nezvako zvakasarudzika uye kukupa iwe pre-kutengesa, pa-kutengesa uye mushure-kutengesa-vanopaChina CVD Tube Furnace uye CVD Tube Furnace Chemical Vapor Deposition, Mumusika unowedzera kukwikwidza, Nebasa rechokwadi zvinhu zvemhando yepamusoro uye mukurumbira wakakodzera, tinogara tichipa vatengi rutsigiro pazvinhu uye matekiniki ekuwana kubatana kwenguva refu. Kurarama nemhando, kusimudzira nechikwereti ndiko kuita kwedu nekusingaperi, Isu tinotenda zvakasimba kuti mushure mekushanya kwako tichave vadyidzani venguva refu.

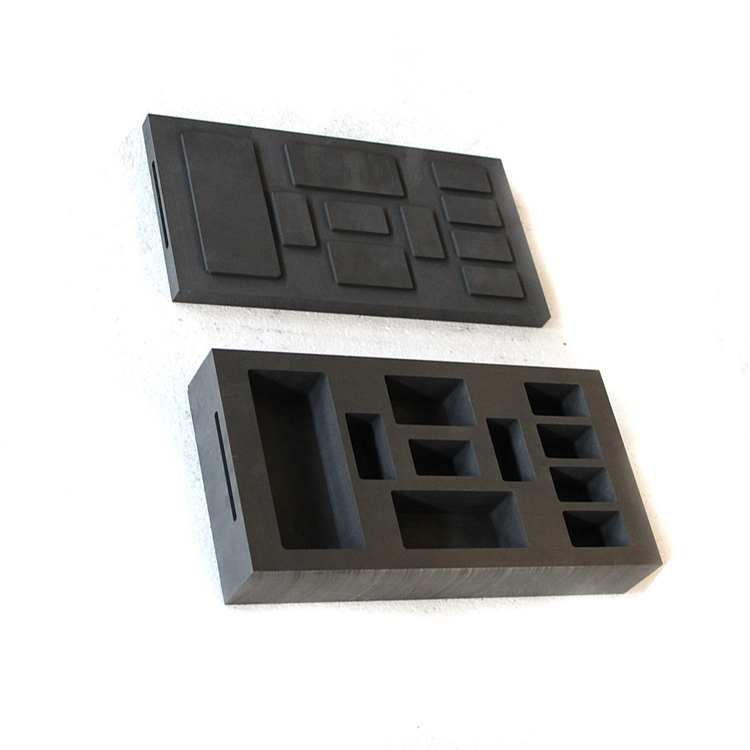

Carbon / carbon composite(zvino zvinozonzi "C / C kana CFC") imhando yezvakaumbwa zvinhu zvakavakirwa pakabhoni uye inosimbiswa nekabhoni fiber uye zvigadzirwa zvayo (carbon fiber preform). Iine zvose inertia yekabhoni uye simba rakakwirira re carbon fiber. Iyo ine yakanaka yemagetsi zvivakwa, kupisa kupisa, corrosion resistance, friction damping uye thermal uye magetsi conductivity maitiro.

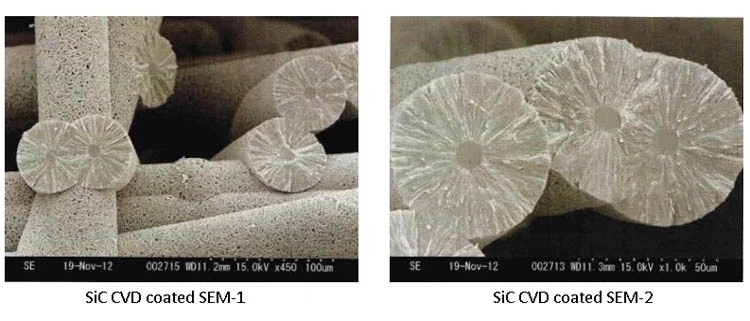

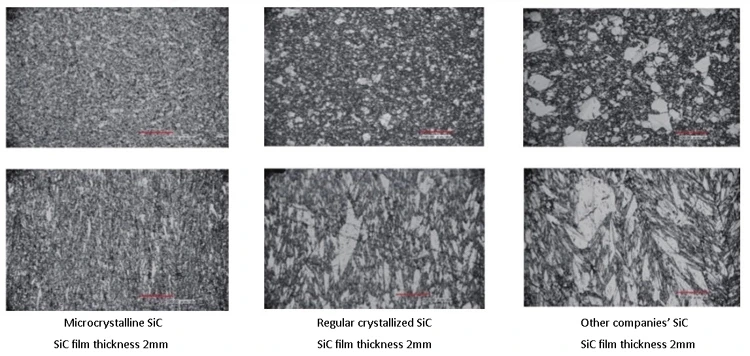

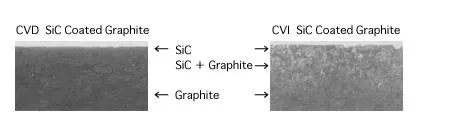

CVD-SiCCoating ine hunhu hwechimiro chakafanana, compact material, yakakwirira tembiricha kuramba, oxidation kuramba, kuchena kwakanyanya, acid & alkali kuramba uye organic reagent, ine yakagadzikana yemuviri nemakemikari zvinhu.

Zvichienzaniswa nepamusoro-kuchena graphite zvinhu, graphite inotanga oxidize pa 400C, iyo inokonzera kurasikirwa kwehupfu nekuda kweoxidation, zvichiita kuti kusvibiswa kwezvakatipoteredza kune zvigadzirwa zveparipheral uye vacuum chambers, uye kuwedzera kusvibiswa kwepamusoro-kuchena kwezvakatipoteredza.

Nekudaro, SiC coating inogona kuchengetedza kugadzikana kwemuviri uye kemikari pa1600 madhigirii, Inoshandiswa zvakanyanya muindasitiri yemazuva ano, kunyanya muindasitiri yesemiconductor.

Kambani yedu inopa SiC yekuvhara maitiro masevhisi neCVD nzira pamusoro pegraphite, ceramics uye zvimwe zvinhu, kuitira kuti akakosha magasi ane kabhoni nesilicon aite pakupisa kwepamusoro kuti awane kuchena kwakanyanya kweSiC mamorekuru, mamorekuru akaiswa pamusoro pezvinhu zvakavharwa, kugadzira SIC inodzivirira layer. Iyo SIC yakaumbwa inosungirirwa zvakasimba kune iyo graphite base, ichipa iyo graphite base yakakosha zvivakwa, nekudaro ichiita pamusoro peiyo graphite compact, Porosity-isina, yakakwirira tembiricha kuramba, corrosion kuramba uye oxidation kuramba.

Main features:

1. High tembiricha oxidation kuramba:

iyo oxidation kuramba ichiri yakanaka kwazvo kana tembiricha yakakwira kusvika 1600 C.

2. Kuchena kwepamusoro: yakagadzirwa nemakemikari vapor deposition pasi pekushisa kwakanyanya kweklorination mamiriro.

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, munyu uye organic reagents.

Zvinonyanya Kutaurwa zveCVD-SIC Coatings:

| SiC-CVD | ||

| Density | (g/cc)

| 3.21 |

| Flexural simba | (Mpa)

| 470 |

| Kuwedzera kupisa | (10-6/K) | 4

|

| Thermal conductivity | (W/mK) | 300

|