The 6 Inch Semi Insulating SiC Wafer ho tloha VET Energy ke tharollo e tsoetseng pele bakeng sa lisebelisoa tse matla le tse phahameng, tse fanang ka conductivity e phahameng ea mocheso le ho kenya motlakase. Li-wafers tsena tsa semi-insulating li bohlokoa ho nts'etsopele ea lisebelisoa tse kang li-amplifiers tsa RF, li-switches tsa motlakase le likarolo tse ling tsa motlakase o phahameng. VET Energy e netefatsa boleng le ts'ebetso e ts'oanang, e etsa hore li-wafers tsena e be tse loketseng mekhoa e mengata ea ho etsa semiconductor.

Ntle le thepa ea bona e ikhethang ea ho itšireletsa, li-wafer tsena tsa SiC li tsamaisana le lisebelisoa tse fapaneng ho kenyeletsoa Si Wafer, SiC Substrate, SOI Wafer, SiN Substrate, le Epi Wafer, e leng se etsang hore li feto-fetohe bakeng sa mefuta e fapaneng ea lits'ebetso tsa tlhahiso. Ho feta moo, lisebelisoa tse tsoetseng pele joalo ka Gallium Oxide Ga2O3 le AlN Wafer li ka sebelisoa hammoho le li-wafer tsena tsa SiC, li fana ka phetoho e kholo le ho feta lisebelisoa tsa elektroniki tse matla a phahameng. Li-wafers li etselitsoe ho hokahana ka mokhoa o se nang moeli le litsamaiso tse sebetsang tsa maemo a indasteri joalo ka litsamaiso tsa Cassette, tse netefatsang boiketlo ba tšebeliso maemong a tlhahiso ea bongata.

VET Energy e fana ka potefolio e felletseng ea li-semiconductor substrates, ho kenyeletsoa Si Wafer, SiC Substrate, SOI Wafer, SiN Substrate, Epi Wafer, Gallium Oxide Ga2O3, le AlN Wafer. Lihlahisoa tsa rona tse fapaneng li fana ka litlhoko tsa lits'ebetso tse fapaneng tsa elektroniki, ho tloha ho lisebelisoa tsa motlakase ho isa ho RF le optoelectronics.

6 inch semi-insulating SiC wafer e fana ka melemo e mengata:

Matla a phahameng a ho senyeha ha matla: Lekhalo le pharaletseng la SiC le nolofalletsa matla a ho senya, a lumellang lisebelisoa tsa motlakase tse sebetsang hantle le tse sebetsang hantle.

Ts'ebetso ea mocheso o phahameng: Ts'ebetso e ntle ea mocheso oa SiC e nolofalletsa ts'ebetso ka mocheso o phahameng, ho ntlafatsa ts'epahalo ea sesebelisoa.

Ho hanyetsa ho tlase: Lisebelisoa tsa SiC li bonts'a khanyetso e tlase, li fokotsa tahlehelo ea matla le ho ntlafatsa ts'ebetso ea matla.

VET Energy e fana ka li-wafers tsa SiC tse ka tloahelehang ho fihlela litlhoko tsa hau tse ikhethileng, ho kenyeletsoa botenya bo fapaneng, maemo a doping, le liphetho tsa bokaholimo. Sehlopha sa rona sa litsebi se fana ka ts'ehetso ea tekheniki le ts'ebeletso ea morao-rao ea thekiso ho netefatsa katleho ea hau.

LIEKETSENG TSIETSO

*n-Pm=n-mofuta oa Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulation

| Ntho | 8-Intshi | 6-Intshi | 4-Intshi | ||

| nP | n-Pm | n-Pes | SI | SI | |

| TTV(GBIR) | ≤6um | ≤6um | |||

| Bow(GF3YFCD)-Boleng bo Felletseng | ≤15μm | ≤15μm | ≤25μm | ≤15μm | |

| Warp(GF3YFER) | ≤25μm | ≤25μm | ≤40μm | ≤25μm | |

| LTV(SBIR) -10mmx10mm | <2μm | ||||

| Wafer Edge | Beveling | ||||

SEBAKA PHETHA

*n-Pm=n-mofuta oa Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulation

| Ntho | 8-Intshi | 6-Intshi | 4-Intshi | ||

| nP | n-Pm | n-Pes | SI | SI | |

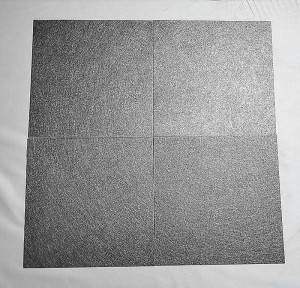

| Surface Finish | Mahlakore a mabeli a Optical Polish, Si- Face CMP | ||||

| SurfaceRoughness | (10um x 10um) Si-FaceRa≤0.2nm | (5umx5um) Si-Face Ra≤0.2nm | |||

| Li-Chips tsa Edge | Ha ho e dumellwe (bolelele le bophara≥0.5mm) | ||||

| Li-indent | Ha ho le e 'ngoe e Lumelloang | ||||

| Scratches(Si-Face) | Kty.≤5, Kakaretso | Kty.≤5, Kakaretso | Kty.≤5, Kakaretso | ||

| Mapetso | Ha ho le e 'ngoe e Lumelloang | ||||

| Kenyelletso ea Edge | 3mm | ||||

-

Moetsi oa banadium stream battery pack ce...

-

PEM cell gas diffusion layer platinum-coated ti...

-

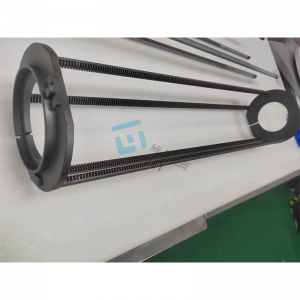

Silicon Carbide Coated Graphite Substrate bakeng sa S...

-

Hydrogen Fuel Cell Stack Power High Precision H...

-

Metsi a pholile enjene ea hydrogen fuel cell ntle le ...

-

Sephaephe sa Silicon Carbide sa boholo bo boholo bo nchafalitsoeng ...