Kufotokozera:

Silicon Carbide ili ndi katundu wabwino kwambiri wosamva dzimbiri, mphamvu zamakina apamwamba, matenthedwe apamwamba kwambiri, kudzipaka bwino komwe kumagwiritsidwa ntchito ngati nkhope zosindikizira, machubu ndi machubu mumlengalenga, makina, zitsulo, kusindikiza ndi utoto, zakudya, mankhwala, mafakitale amagalimoto ndi zina zambiri. pa. Pamene nkhope za sic zikuphatikizidwa ndi nkhope za graphite kukangana kumakhala kochepa kwambiri ndipo kungapangidwe kukhala zidindo zamakina zomwe zimatha kugwira ntchito pazofunikira kwambiri.

Silicon Carbide Basic Properties:

-Kuchulukana kochepa

- High matenthedwe conductivity (pafupi ndi aluminium)

-Kulimbana bwino ndi kutentha kwa kutentha

- Umboni wamadzi ndi gasi

- High refractoriness (angagwiritsidwe ntchito pa 1450 ℃ mu mpweya ndi 1800 ℃ mu ndale chikhalidwe)

-Simakhudzidwa ndi dzimbiri ndipo samanyowa ndi aluminiyamu yosungunuka kapena zinc yosungunuka

-Kuuma kwakukulu

-Kugundana kochepa kwambiri

-Kukana kwa abrasion

-Imalimbana ndi ma acid oyambira komanso amphamvu

- Zomveka

-Mkulu wamakina mphamvu

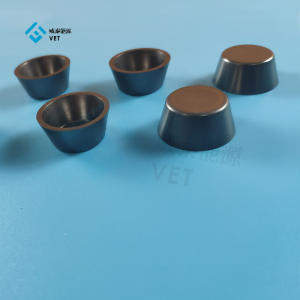

Kugwiritsa ntchito Silicon Carbide:

- Zisindikizo zamakina, ma bearing, ma thrust bears, ndi zina

-Malumikizidwe ozungulira

- Semiconductor ndi zokutira

-Pads Pampu zigawo

-Zigawo zamankhwala

-Magalasi a machitidwe a laser mafakitale.

- Ma reactor opitilira, zosinthira kutentha, ndi zina.

Mbali

Silicon carbide imapangidwa m'njira ziwiri:

1) Sintered silicon carbide

Pambuyo pazitsulo zopanda mphamvu za sintered silicon carbide zimakhazikika, chithunzi cha kristalo pansi pa 200X kuwala kwa microscope chimasonyeza kuti kugawa ndi kukula kwa makhiristo ndi yunifolomu, ndipo kristalo yaikulu sikudutsa 10μm.

2) Zochita sintered silicon carbide

Pambuyo pa zomwe sintered silicon carbide imagwira gawo lathyathyathya komanso losalala la zinthuzo, kristalo

kugawa ndi kukula pansi pa 200X kuwala kwa microscope ndi yunifolomu, ndipo zaulere za silicon sizidutsa 12%.

| Katundu Waumisiri | |||

| Mlozera | Chigawo | Mtengo | |

| Dzina lazinthu | Pressureless Sintered Silicon Carbide | Reaction Sintered Silicon Carbide | |

| Kupanga | SSiC | Mtengo wa RBSiC | |

| Kuchulukana Kwambiri | g/cm3 | 3.15 ± 0.03 | 3 |

| Flexural Mphamvu | MPa (kpsi) | 380 (55) | 338 (49) |

| Compressive Mphamvu | MPa (kpsi) | 3970 (560) | 1120 (158) |

| Kuuma | Knoop | 2800 | 2700 |

| Kuphwanya Kukhazikika | MPa m1/2 | 4 | 4.5 |

| Thermal Conductivity | W/mk | 120 | 95 |

| Coefficient of Thermal Expansion | 10-6 / ° C | 4 | 5 |

| Kutentha Kwapadera | Uwu/g 0k | 0.67 | 0.8 |

| Kutentha kwakukulu mumlengalenga | ℃ | 1500 | 1200 |

| Elastic Modulus | Gpa | 410 | 360 |

-

Flexible graphite pepala High chiyero mkulu mpweya ...

-

Factory kupereka flexible graphite paper artifici...

-

Kaboni Wagalasi Wapamwamba Wapamwamba Wosagwirizana ndi dzimbiri ...

-

Wopanga amapereka mwachindunji apamwamba ...

-

PECVD thireyi / chonyamulira ntchito mpweya CHIKWANGWANI kulimbikitsa...

-

Zam'manja zosunga zobwezeretsera Mphamvu Cell Pem Membrane El...