Me kā mākou hoʻokele maikaʻi, ka mana ʻenehana ikaika a me ke kaʻina hana koʻikoʻi maikaʻi loa, hoʻomau mākou i ka hāʻawi ʻana i kā mākou mea kūʻai aku i ke kūlana kiʻekiʻe kiʻekiʻe, nā kumukūʻai kūʻai kūpono a me nā mea hoʻolako nui. Ke manaʻo nei mākou e lilo i waena o kāu mau hoa hilinaʻi nui a loaʻa iā ʻoe ka ʻoluʻolu no nā Kūʻai Kūʻai Kūʻai maikaʻi ʻo China Abrasive Polishing and Sandblasting Silicon Carbide NanoʻO Sicme ka Good Thermal Conductivity, ʻO kā mākou pahuhopu hope loa ke kūlana ma ke ʻano he inoa kiʻekiʻe a alakaʻi hoʻi ma ke ʻano he paionia i kā mākou kahua. ʻIke mākou i kā mākou ʻike huahana i ka hana ʻana i ka mea hana e loaʻa ai ka hilinaʻi o ka mea kūʻai aku, makemake e hui pū a hana pū i kahi manawa lōʻihi ʻoi aku ka maikaʻi me ʻoe!

Me kā mākou hoʻokele maikaʻi, ka mana ʻenehana ikaika a me ke kaʻina hana koʻikoʻi maikaʻi loa, hoʻomau mākou i ka hāʻawi ʻana i kā mākou mea kūʻai aku i ke kūlana kiʻekiʻe kiʻekiʻe, nā kumukūʻai kūʻai kūpono a me nā mea hoʻolako nui. Manaʻo mākou e lilo i waena o kāu mau hoa hilinaʻi nui a loaʻa iā ʻoe ka hauʻoliKina Silicon Carbide, ʻO Sic, ʻO kā mākou pahuhopu "e hoʻolako i nā huahana a me nā hoʻonā a me ka lawelawe maikaʻi loa no kā mākou mea kūʻai aku, no laila ke maopopo nei mākou e loaʻa iā ʻoe kahi pōmaikaʻi ma o ka hui pū ʻana me mākou". Inā makemake ʻoe i kekahi o kā mākou mea kūʻai a makemake paha e kūkākūkā i kahi kauoha maʻamau, e ʻoluʻolu e leka uila iā mākou. Ke kakali nei mākou i ka hoʻokumu ʻana i nā pilina ʻoihana kūleʻa me nā mea kūʻai aku hou a puni ka honua i ka wā e hiki mai ana.

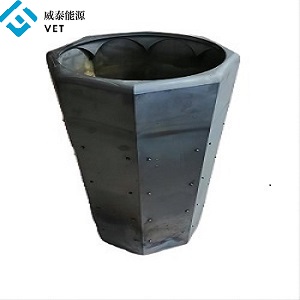

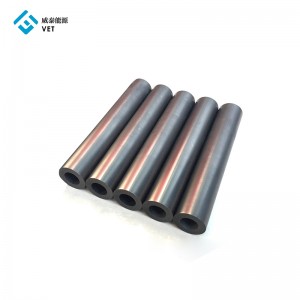

Hōʻike huahana

Hāʻawi kā mākou hui i nā lawelawe kaʻina hana hoʻoheheʻe SiC ma ke ʻano CVD ma ka ʻili o ka graphite, ceramics a me nā mea ʻē aʻe, i hiki ai i nā kinoea kūikawā i loaʻa ke kalapona a me ke silika i ke kiʻekiʻe kiʻekiʻe e loaʻa ai nā molekala SiC maʻemaʻe kiʻekiʻe. e hana ana i ka papa pale SIC.

Nā hiʻohiʻona nui:

1. Kiʻekiʻe wela oxidation kū'ē:

ʻoi aku ka maikaʻi o ka pale ʻana i ka oxidation ke kiʻekiʻe ka mahana e like me 1600 C.

2. Maʻemaʻe kiʻekiʻe: hana ʻia e ka hoʻoheheʻe ʻana i ka mahu ma lalo o ke kūlana chlorination kiʻekiʻe.

3. Erosion kū'ē: kiʻekiʻe paakiki, paʻaʻiliʻili, maikaʻi particles.

4. Ke kū'ē i ka corrosion: acid, alkali, paʻakai a me nā mea hoʻoulu.

Nā kiko'ī nui o ka CVD-SIC Coating

| Nā Waiwai SiC-CVD | ||

| Hoʻokumu Crystal | Māhele FCC β | |

| ʻO ka mānoanoa | g/cm ³ | 3.21 |

| ʻoʻoleʻa | ʻO ka paʻakikī o Vickers | 2500 |

| Ka nui o ka palaoa | μm | 2~10 |

| Maemae Kemika | % | 99.99995 |

| Kaha Wela | J·kg-1 ·K-1 | 640 |

| Mahana Sublimation | ℃ | 2700 |

| Ikaika Pilikino | MPa (RT 4-point) | 415 |

| ʻO Young's Modulus | Gpa (4pt piko, 1300 ℃) | 430 |

| Hoʻonui wela (CTE) | 10-6K-1 | 4.5 |

| ʻO ke kau wela wela | (W/mK) | 300 |

-

Kiʻekiʻe ʻO Resin Antimony Impregnated Treatme...

-

ʻO ODM Factory 3V To12V Micro Electric Mini Vacuum ...

-

Hāʻawi i ka OEM/ODM Heat Resistance Carbon Raschig R...

-

ʻO OEM Kina nā ʻāpana ʻokoʻa i hoʻoheheʻe ʻia ʻo Graphite Block

-

25v Drone Hydrogen Fuel Cell 2000w Hydrogen Fue...

-

Mea hana no Kina ke kumu kūʻai maikaʻi loa hou huahana G...