Carbon / carbon composites(daga baya ana kiranta "C/C ko CFC”) wani nau'i ne na nau'i mai nau'i wanda ya dogara da carbon kuma an ƙarfafa shi ta hanyar carbon fiber da samfuransa (carbon fiber preform). Yana da duka inertia na carbon da babban ƙarfin carbon fiber. Yana da kyawawan kaddarorin inji, juriya mai zafi, juriya na lalata, damping damping da thermal da halayen halayen lantarki.

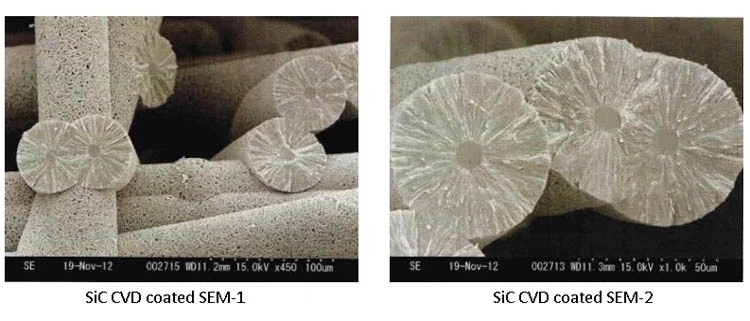

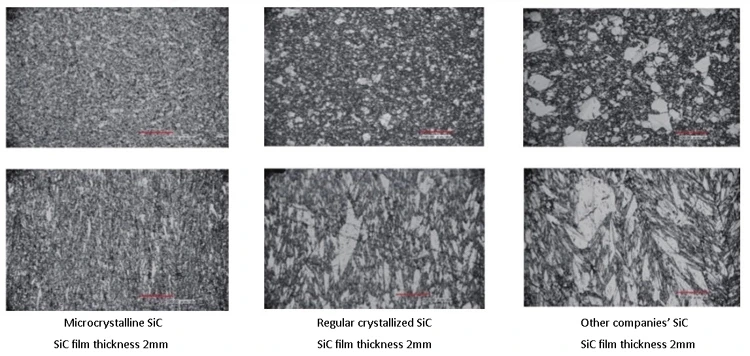

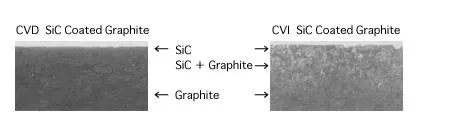

CVD-SiCshafi yana da halaye na uniform tsarin, m abu, high zafin jiki juriya, hadawan abu da iskar shaka juriya, high tsarki, acid&alkali juriya da Organic reagent, tare da barga jiki da sinadaran Properties.

Idan aka kwatanta da kayan aikin graphite mai tsabta, graphite ya fara oxidize a 400C, wanda zai haifar da asarar foda saboda iskar shaka, haifar da gurɓataccen muhalli ga na'urorin da ke kewaye da ɗakunan sarari, da haɓaka ƙazantattun yanayi mai tsafta.

Koyaya, murfin SiC na iya kiyaye kwanciyar hankali ta jiki da sinadarai a digiri 1600, Ana amfani da shi sosai a masana'antar zamani, musamman a masana'antar semiconductor.

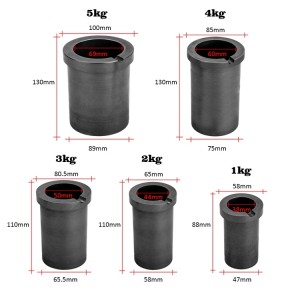

Kamfaninmu yana ba da sabis na tsarin aikin SiC ta hanyar CVD akan saman graphite, yumbu da sauran kayan, don haka iskar gas na musamman da ke ɗauke da carbon da silicon suna amsawa a babban zafin jiki don samun ƙwayoyin SiC masu tsabta, ƙwayoyin da aka ajiye akan saman kayan da aka rufe, kafa SIC kariya Layer. SIC da aka kafa yana da ƙarfi ga tushen graphite, yana ba da ginshiƙi na musamman na graphite, don haka yin saman ƙaramin graphite, mara ƙarfi, juriya mai girma, juriya na lalata da juriya na iskar shaka.

Babban fasali:

1. High zafin jiki oxidation juriya:

juriya na iskar oxygen har yanzu yana da kyau sosai lokacin da zafin jiki ya kai 1600 C.

2. Babban tsarki: sanya ta hanyar tururin sinadarai a ƙarƙashin yanayin chlorination mai zafi.

3. Juriya juriya: babban taurin, m surface, lafiya barbashi.

4. Lalata juriya: acid, alkali, gishiri da kuma Organic reagents.

Babban Takaddun Shafi na CVD-SIC Coatings:

| SiC-CVD | ||

| Yawan yawa | (g/cc)

| 3.21 |

| Ƙarfin sassauƙa | (Mpa)

| 470 |

| Fadada thermal | (10-6/K) | 4

|

| Ƙarfafawar thermal | (W/mK) | 300

|