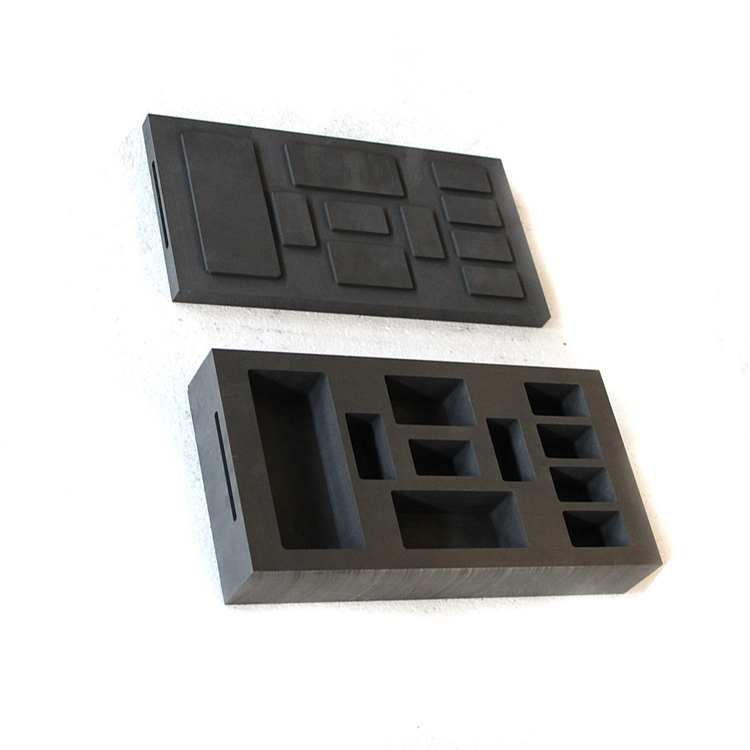

TheRahoton da aka ƙayyade na CVDCC Composite Mould, Carbon-Carbon Composite Mould, C/C Mold daga vet-china wani babban aiki mold tsara don masana'antu da bukatar high thermal da sinadaran juriya. Thehadadden carbon-carbonTsarin, haɓakawa tare da murfin CVD SiC (Silicon Carbide), yana ba da dorewa na musamman da kwanciyar hankali a ƙarƙashin matsanancin yanayin zafi, yana mai da shi manufa don aikace-aikacen buƙatu kamar masana'antar semiconductor, sararin samaniya, da sassan kera motoci.

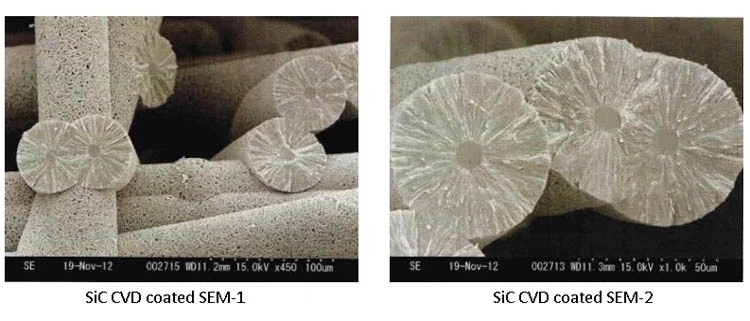

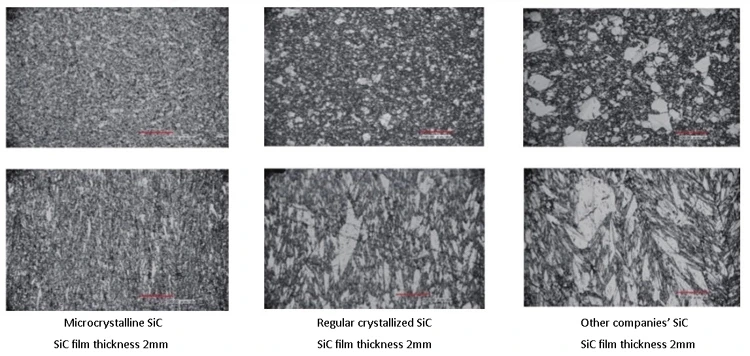

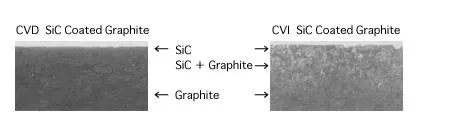

TheCVD SiC shafiyana ba da juriya na ban mamaki ga lalacewa da iskar shaka, yana tsawaita tsawon rayuwar ƙirar da kuma tabbatar da ingantaccen aiki a cikin yanayi mara kyau. Wannan fasaha na ci gaba na sutura kuma yana inganta taurin saman, yana kare ƙura a lokacin matakan zafi mai zafi da hana lalacewa ko lalacewa. Samfuran vet-china sun dace sosai don masana'antu masu amfani da suCVD SiC zobeda aka gyara, samar da mafi kyawun bayani don ƙirƙira madaidaici.

Baya ga suturar SiC, daCVD TaC shafiHakanan za'a iya amfani da shi don haɓaka juriya na sinadarai, yin ƙirar ƙira don aikace-aikace daban-daban waɗanda ke buƙatar kariya daga abubuwa masu lalata. Ƙwarewar Vet-china a cikin CVD SiC da C/C composites yana tabbatar da cewa an ƙera kowane nau'in ƙira tare da daidaito, yana ba da babban aiki a cikin masana'antu da mahalli na fasaha.

Haɗuwa da CVD SiC da carbon-carbon composite kayan yana tabbatar da cewa CVD SiC Coating CC Composite Mould, Carbon-Carbon Composite Mould, C / C Mold ya fi dacewa a cikin matakai da ke tattare da zafi mai zafi, sinadarai, da damuwa na inji, samar da masu amfani tare da dogon lokaci, amintaccen mold bayani.

Babban fasali:

1. High zafin jiki oxidation juriya:

juriya na iskar oxygen har yanzu yana da kyau sosai lokacin da zafin jiki ya kai 1600 C.

2. Babban tsarki: sanya ta hanyar tururin sinadarai a ƙarƙashin yanayin chlorination mai zafi.

3. Juriya juriya: babban taurin, m surface, lafiya barbashi.

4. Lalata juriya: acid, alkali, gishiri da kuma Organic reagents.

Babban Takaddun Shafi na CVD-SIC Coatings:

| SiC-CVD | ||

| Yawan yawa | (g/cc)

| 3.21 |

| Ƙarfin sassauƙa | (Mpa)

| 470 |

| Fadada thermal | (10-6/K) | 4

|

| Ƙarfafawar thermal | (W/mK) | 300

|