Incazelo:

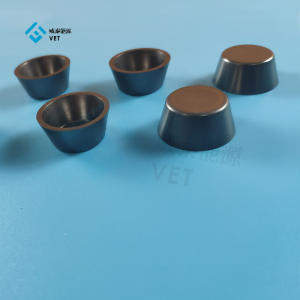

I-Silicon Carbide inendawo yokumelana nokugqwala okuhle kakhulu, amandla amakhulu emishini, amandla aphezulu okushisa, ukuzigcoba okuhle okusetshenziswa njengobuso bophawu, amabherethi namashubhu kumkhumbi-mkhathi, imishini, i-metallurgy, ukuphrinta nokudaya, ukudla, imithi, imboni yezimoto nokunye. ku. Lapho ubuso be-sic buhlanganiswe nobuso be-graphite ukungqubuzana kuncane kakhulu futhi kungenziwa kube izigxivizo zemishini ezikwazi ukusebenza ngezidingo eziphezulu zokusebenza.

Izakhiwo eziyisisekelo ze-Silicon Carbide:

-Ukuminyana okuphansi

-Ukushisa okuphezulu kwe-thermal (eduze ne-aluminium)

-Ukumelana nokushaqeka okuhle kokushisa

-Ubufakazi boketshezi negesi

-I-refractoriness ephezulu (ingasetshenziswa ku-1450 ℃ emoyeni kanye ne-1800 ℃ emkhathini ongathathi hlangothi)

-Ayithintwa ukugqwala futhi ayimanzi nge-aluminium encibilikisiwe noma i-zinc encibilikisiwe

-Ukuqina okuphezulu

-I-coefficient yokungqubuzana ephansi

-Ukumelana nemihuzuko

-Imelana nama-asidi ayisisekelo futhi aqinile

-Kuyaphucuzeka

-Amandla aphezulu emishini

Isicelo seSilicon Carbide:

- Izigxivizo zemishini, ama-bearings, ama-thrust bears, njll

-Ukuzungeza amalunga

- Semiconductor kanye enamathela

-Pads Pump izingxenye

-Izingxenye zamakhemikhali

-Izibuko zezinhlelo ze-laser zezimboni.

- Ama-reactors agelezayo aqhubekayo, izishintshisi zokushisa, njll.

Isici

I-silicon carbide yenziwa ngezindlela ezimbili:

1) I-silicon carbide engenasici

Ngemva kokuba impahla ye-silicon carbide engacindezeli isifakiwe, umdwebo wesigaba se-crystal ngaphansi kwe-200X optical microscope ubonisa ukuthi ukusatshalaliswa nobukhulu bamakristalu kufana, futhi ikristalu enkulu kunazo zonke ayidluli i-10μm.

2) Ukusabela sintered Silicon carbide

Ngemuva kokusabela i-silicon carbide iphatha ngamakhemikhali ingxenye eyisicaba nebushelelezi yezinto ezibonakalayo, ikristalu

ukusatshalaliswa nosayizi ngaphansi kwe-200X optical microscope kufana, futhi okuqukethwe kwe-silicon yamahhala akudluli u-12%.

| Izakhiwo Zobuchwepheshe | |||

| Inkomba | Iyunithi | Inani | |

| Igama Lempahla | Pressureless Sintered Silicon Carbide | Ukusabela Sintered Silicon Carbide | |

| Ukwakheka | I-SSiC | I-RBSiC | |

| Ukuminyana kwenqwaba | g/cm3 | 3.15 ± 0.03 | 3 |

| Amandla e-Flexural | I-MPa (kpsi) | 380(55) | 338(49) |

| Amandla Acindezelayo | I-MPa (kpsi) | 3970(560) | 1120(158) |

| Ukuqina | Knoop | 2800 | 2700 |

| Breaking Tenacity | I-MPa m1/2 | 4 | 4.5 |

| I-Thermal Conductivity | W/mk | 120 | 95 |

| I-Coefficient of Thermal Expansion | 10-6/°C | 4 | 5 |

| Ukushisa Okuthize | I-Joule/g 0k | 0.67 | 0.8 |

| Izinga lokushisa eliphezulu emoyeni | ℃ | 1500 | 1200 |

| I-Elastic Modulus | I-Gpa | 410 | 360 |

-

Iphepha le-graphite eliguquguqukayo Ukuhlanzeka okuphezulu kwekhabhoni ephezulu...

-

Ifekthri inikezela nge-flexible graphite paper artifici...

-

Ikhabhoni Yengilazi Yekhwalithi Ephakeme Ekwazi ukumelana nokugqwala ...

-

Umkhiqizi uhlinzeka ngokuqondile ngekhwalithi ephezulu...

-

Ithreyi/isithwali se-PECVD sisebenzisa i-carbon fibre reinforce...

-

Isipele Esiphathekayo Samandla Isibaseli Cell Pem Membrane El...