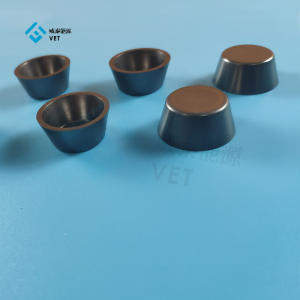

I-VET Energy isebenzisa ubumsulwa obuphezulu kakhului-silicon carbide (SiC)akhiwe ngokufakwa komhwamuko wamakhemikhali(CVD)njengomthombo wokukhulaAmakristalu e-SiCngokuthuthwa komhwamuko obonakalayo (PVT). Ku-PVT, impahla yomthombo ilayishwa ku-acruciblefuthi ifakwe ngaphansi kwekristalu lembewu.

Kudingeka umthombo wokuhlanzeka okuphezulu ukuze kukhiqizwe ikhwalithi ephezuluAmakristalu e-SiC.

I-VET Energy igxile ekuhlinzekeni i-SiC enezinhlayiyana ezinkulu ze-PVT ngenxa yokuthi inokuminyana okuphezulu kunento eyizinhlayiyana ezincane ezakhiwe ukushiswa okuzenzakalelayo kwamagesi aqukethe u-Si kanye no-C. Ngokungafani ne-solid-phase sintering noma ukusabela kuka-Si no-C, akudingi isithando somlilo esizinikele noma isinyathelo sokushisa isikhathi esiningi esithandweni sokukhula. Le nto eyizinhlayiya ezinkulu inezinga elicishe libe njalo lokuhwamuka, elenza ngcono ukufana kokugijima kuya kokugijima.

Isingeniso:

1. Lungiselela umthombo we-block ye-CVD-SiC: Okokuqala, udinga ukulungisa umthombo we-block we-CVD-SiC wekhwalithi ephezulu, ovame ukuhlanzeka okuphezulu nokuphakama okuphezulu. Lokhu kungalungiswa ngendlela ye-chemical vapor deposition (CVD) ngaphansi kwezimo ezifanele zokusabela.

2. Ukulungiswa kwe-substrate: Khetha i-substrate efanelekile njenge-substrate yokukhula kwekristalu eyodwa ye-SiC. Izinto ezisetshenziswa kakhulu ze-substrate zifaka i-silicon carbide, i-silicon nitride, njll., ehambisana kahle nekristalu eyodwa ye-SiC ekhulayo.

3. Ukushisa kanye ne-sublimation: Beka umthombo wokuvimba we-CVD-SiC kanye ne-substrate esithandweni sokushisa esiphezulu futhi unikeze izimo ezifanele ze-sublimation. I-Sublimation isho ukuthi ekushiseni okuphezulu, umthombo webhulokhi ushintsha ngokuqondile usuka kokuqinile uye esimweni somhwamuko, bese uphinda ujiya endaweni engaphansi ukuze wenze ikristalu eyodwa.

4. Ukulawulwa kwezinga lokushisa: Phakathi nenqubo ye-sublimation, i-gradient yokushisa nokusabalalisa kwezinga lokushisa kudinga ukulawulwa ngokunembile ukuze kukhuthazwe i-sublimation yomthombo we-block kanye nokukhula kwamakristalu owodwa. Ukulawula izinga lokushisa okufanelekile kungafinyelela ikhwalithi yekristalu efanelekile nezinga lokukhula.

5. Ukulawulwa komkhathi: Phakathi nenqubo yokwenziwa kwe-sublimation, umkhathi wokusabela nawo udinga ukulawulwa. I-high-purity gas inert (njenge-argon) ivame ukusetshenziswa njengegesi elithwalayo ukuze kugcinwe ukucindezela okufanele nokuhlanzeka nokuvimbela ukungcoliswa ukungcola.

6. Ukukhula kwekristalu okukodwa: Umthombo webhulokhi we-CVD-SiC uthola ukuguqulwa kwesigaba somhwamuko phakathi nenqubo ye-sublimation futhi uphinde ubuyele endaweni engaphansi ukuze wenze isakhiwo sekristalu esisodwa. Ukukhula okusheshayo kwamakristalu e-SiC eyodwa kungafinyelelwa ngezimo ezifanele ze-sublimation kanye nokulawulwa kwe-gradient lokushisa.

-

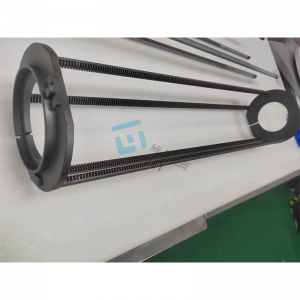

I-High-Quality Tantalum Carbide Tube ye-SiC Crys...

-

Ikhabhoni Yengilazi Yekhwalithi Ephakeme Ekwazi ukumelana nokugqwala ...

-

I-Tantalum carbide coating: ukumelana nokugqokwa, okuphezulu ...

-

Usayizi Omkhulu Owenziwe kabusha weSilicon Carbide Wafer...

-

Isifudumezi Sesifudumezi Se-Graphite Esenziwe Ngokwezifiso Esihlanzekile SiC...

-

Ukusebenza okuphezulu kwe-tantalum carbide embozwe ngezimbotshana...