I-VET Energy silicon carbide (SiC) i-epitaxial wafer yimathiriyeli ye-semiconductor ebanzi ebanzi esebenza kakhulu enokumelana nobushushu obuphezulu, i-frequency ephezulu kunye neempawu zamandla aphezulu. Yi-substrate efanelekileyo kwisizukulwana esitsha sezixhobo zombane zamandla. I-VET Amandla isebenzisa iteknoloji ye-MOCVD epitaxial ephucukileyo ukukhula umgangatho ophezulu we-SiC epitaxial layers kwii-substrates ze-SiC, ukuqinisekisa ukusebenza okugqwesileyo kunye nokuhambelana kwe-wafer.

I-Silicon Carbide yethu (i-SiC) ye-Epitaxial Wafer inikezela ngokuhambelana okugqwesileyo kunye nezixhobo ezahlukeneyo ze-semiconductor ezibandakanya i-Si Wafer, i-SiC Substrate, i-SOI Wafer, kunye ne-SiN Substrate. Ngomaleko wayo owomeleleyo we-epitaxial, ixhasa iinkqubo eziphambili ezifana nokukhula kwe-Epi Wafer kunye nokudityaniswa nezinto ezifana ne-Gallium Oxide Ga2O3 kunye ne-AlN Wafer, iqinisekisa ukusetyenziswa ngeendlela ezahlukeneyo kwiitekhnoloji ezahlukeneyo. Eyilwe ukuba ihambelane ne-industry-standard Cassette handling systems, iqinisekisa ukusebenza ngokufanelekileyo kunye nokulungelelaniswa kwemisebenzi kwiindawo zokwenziwa kwe-semiconductor.

Umgca wemveliso we-VET Energy awuphelelanga kwii-wafers ze-SiC epitaxial. Sikwabonelela ngoluhlu olubanzi lwezixhobo ze-semiconductor substrate, ezibandakanya iSi Wafer, iSiC Substrate, i-SOI Wafer, iSiN Substrate, i-Epi Wafer, njl. Ukongeza, sikwaqhuba ngokukhutheleyo izinto ezintsha ze-semiconductor ze-bandgap, ezifana ne-Gallium Oxide Ga2O3 kunye ne-AlN Wafer, ukuhlangabezana nebango lexesha elizayo lezixhobo zombane ze-elektroniki.

IINGCACISO ZOKUPHAZAMISEKA

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulation

| Into | 8-intshi | 6-Intshi | 4-intshi | ||

| nP | n-Pm | n-Nd | SI | SI | |

| TTV(GBIR) | ≤6um | ≤6um | |||

| I-Bow(GF3YFCD)-Ixabiso elipheleleyo | ≤15μm | ≤15μm | ≤25μm | ≤15μm | |

| Warp(GF3YFER) | ≤25μm | ≤25μm | ≤40μm | ≤25μm | |

| I-LTV(SBIR)-10mmx10mm | <2μm | ||||

| Wafer Edge | Beveling | ||||

UPHANDO GQIBELA

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulation

| Into | 8-intshi | 6-Intshi | 4-intshi | ||

| nP | n-Pm | n-Nd | SI | SI | |

| Umphezulu Gqiba | Icala eliphindwe kabini le-Optical Polish, iSi- Face CMP | ||||

| Ubunzima boMphezulu | (10um x 10um) Si-FaceRa≤0.2nm | (5umx5um) Si-Face Ra≤0.2nm | |||

| IiChips zoMda | Akukho okuvunyelweyo (ubude nobubanzi≥0.5mm) | ||||

| Iindenti | Akukho Ivumelekileyo | ||||

| Imikrwelo(Si-Face) | Ubuninzi.≤5,Yongezeleka | Ubuninzi.≤5,Yongezeleka | Ubuninzi.≤5,Yongezeleka | ||

| Iintanda | Akukho Ivumelekileyo | ||||

| Ukungabandakanywa kuMda | 3mm | ||||

-

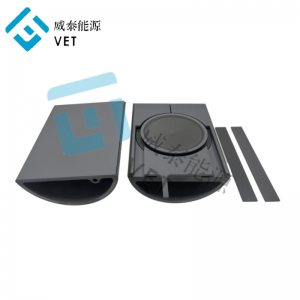

I-Fuel Cell 1000w 24v Drone Hydrogen Fuel Cell Kit

-

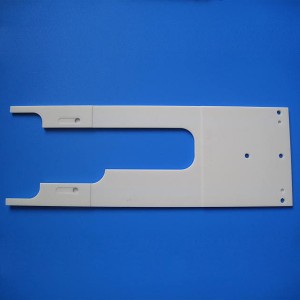

Semiconductor izixhobo ezinokusetyenziswa alumina cer...

-

I-Graphite Plug Resin Impregnated Thrust Bearings...

-

Amandla aphezulu eGraphite/Intambo yeCarbon Fiber yeSe...

-

I-1000w ye-Pemfc Stack ye-Fuel Cell Stack ye-Uav Pemfc...

-

Phezulu nasezantsi kweGraphite Isiqingatha senyanga yeSigaba seSi...