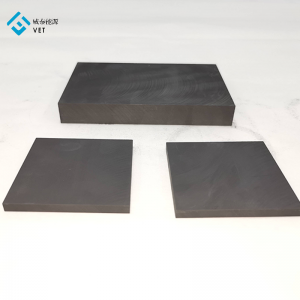

I-VET Energy PECVD inkqubo ye-graphite wafer support yi-core consumable eyenzelwe i-PECVD (i-plasma ephuculweyo yokubeka umphunga wekhemikhali) inkqubo. Le mveliso yenziwe ngezinto ezicocekileyo, ezinoxinano oluphezulu lwegraphite, ezinokumelana nobushushu obuphezulu, ukumelana nokugqwala, ukuzinza kwe-dimensional kunye nezinye iimpawu, inokubonelela ngeqonga lenkxaso elizinzileyo lenkqubo ye-PECVD, ukuqinisekisa ukufana kunye nokunyanzeliswa kwefilimu.

Uyilo lwe-"graphite support" ye-VET Energy graphite wafer support ayikwazi ukuxhasa ngokufanelekileyo i-wafer, kodwa inikezela nokuzinza kwe-thermal kwiqondo lokushisa eliphezulu kunye noxinzelelo oluphezulu lwe-PECVD bume ukuqinisekisa ukuzinza kwenkqubo.

Inkxaso ye-VET Energy PECVD ye-graphite wafer inezi mpawu zilandelayo:

▪Ukucoceka okuphezulu:umxholo wokungcola ophantsi kakhulu, kuphephe ukungcoliseka kwefilimu, ukuqinisekisa umgangatho wefilimu.

▪Ukuxinana okuphezulu:ukuxinana okuphezulu, amandla omatshini aphezulu, anokumelana nobushushu obuphezulu kunye noxinzelelo oluphezulu lwe-PECVD bume.

▪Uzinzo olululo lwemilinganiselo:utshintsho oluncinci lwe-dimensional kwiqondo lokushisa eliphezulu ukuqinisekisa ukuzinza kwenkqubo.

▪I-thermal conductivity egqwesileyo:ngokufanelekileyo ukudlulisa ubushushu ukuthintela ukufudumeza kwewafer.

▪Ukuchasa umhlwa okuqinileyo:Iyakwazi ukuxhathisa ukhukuliseko ngeegesi ezonakalisayo ezahlukeneyo kunye neplasma.

▪Inkonzo eyenzelwe wena:Iitafile zenkxaso yegraphite yobukhulu obuhlukeneyo kunye neemilo zingenziwa ngokwezifiso ngokweemfuno zabathengi.

Imathiriyeli yeGrafite evela kwi-SGL:

| Iparamitha eqhelekileyo: R6510 | |||

| Isalathiso | Umgangatho wovavanyo | Ixabiso | Iyunithi |

| Ubungakanani obuphakathi kweenkozo | ISO 13320 | 10 | μm |

| Unizi lolwapho kuyiwa khona | I-DIN IEC 60413/204 | 1.83 | g/cm3 |

| I-porosity evulekile | DIN66133 | 10 | % |

| Ubungakanani bepore obuphakathi | DIN66133 | 1.8 | μm |

| Ukufikeleleka | DIN 51935 | 0.06 | cm²/s |

| Ubunzima be-Rockwell HR5/100 | I-DIN IEC60413/303 | 90 | HR |

| Ukuxhatshazwa kombane okuthe ngqo | I-DIN IEC 60413/402 | 13 | μΩm |

| Amandla e-Flexural | I-DIN IEC 60413/501 | 60 | MPa |

| Amandla acinezelayo | DIN 51910 | 130 | MPa |

| Imodyuli yolutsha | DIN 51915 | 11.5×10³ | MPa |

| Ukwandiswa kweThermal(20-200℃) | DIN 51909 | 4.2X10-6 | K-1 |

| I-Thermal conductivity (20℃) | DIN 51908 | 105 | Wm-1K-1 |

Yenzelwe ngokukodwa ukwenziwa komgangatho ophezulu wokwenziwa kweeseli zelanga, ezixhasa i-G12 ubungakanani obukhulu bokusetyenzwa kwe-wafer. Uyilo oluphuculweyo lomthwali wonyusa kakhulu umthamo, uvumela amazinga esivuno aphezulu kunye neendleko eziphantsi zemveliso.

| Into | Uhlobo | Inombolo yomphathi wewafer |

| PEVCD Grephite iphenyane - The 156 series | 156-13 isikhephe segrephite | 144 |

| 156-19 isikhephe segrephite | 216 | |

| 156-21 isikhephe segrephite | 240 | |

| 156-23 isikhephe segraphite | 308 | |

| PEVCD Grephite iphenyane - The 125 series | 125-15 isikhephe segrephite | 196 |

| 125-19 isikhephe segrephite | 252 | |

| 125-21 isikhephe se-grphite | 280 |

-

Unikezelo lwebloko yegraphite ecocekileyo ecocekileyo yokunxiba-resis...

-

Ubushushu obuphezulu bepleyiti yegraphite ubushushu obuphezulu kunye...

-

Iphepha elenzelwe ukucoceka okuphezulu kwegraphite, i-artificial s...

-

Ubushushu obuphezulu begraphite intonga ephezulu ...

-

IGraphite/ICarbon Fiber eLukiweyo iNtambo yeVacuum F...

-

New Ultra-high thermal conductivity bhetyebhetye gr...