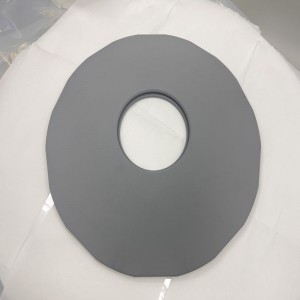

Silicon carbide sheet tray ke karolo ea bohlokoa e sebelisoang lits'ebetsong tse fapaneng tsa tlhahiso ea semiconductor. Re sebelisa theknoloji ea rona e nang le tokelo ea molao ho etsa terei ea silicon carbide e nang le bohloeki bo phahameng ka ho fetesisa, ho ts'oana hantle ha moaparo le bophelo bo botle ba ts'ebeletso, hammoho le ho hanyetsa lik'hemik'hale tse phahameng le thepa ea botsitso ba mocheso.

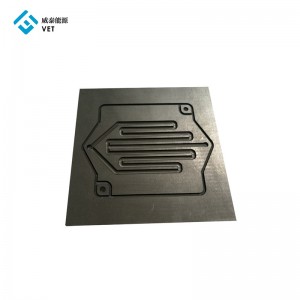

VET Energy ke moetsi oa 'nete oa lihlahisoa tsa graphite le silicon carbide tse nang le liphahlo tse fapaneng tse kang SiC, Tac, pyrolytic carbon, glassy carbon, joalo-joalo, e ka fana ka likarolo tse fapaneng tse hlophisitsoeng bakeng sa indasteri ea semiconductor le photovoltaic. Sehlopha sa rona sa tekheniki se tsoa litsing tse phahameng tsa lipatlisiso tsa lapeng, se ka u fa litharollo tsa lisebelisoa tse eketsehileng bakeng sa hau.

Re ntse re tsoela pele ho nts'etsapele lits'ebetso tse tsoetseng pele ho fana ka lisebelisoa tse tsoetseng pele, 'me re entse theknoloji e ikhethileng e nang le tokelo ea molao, e ka etsang hore maqhama lipakeng tsa pente le substrate e tiee le hore e se ke ea oela habonolo.

Likarolo tsa lihlahisoa tsa rona:

1. Ho hanyetsa mocheso o phahameng oa oxidation ho fihlela ho 1700 ℃.

2. Bohloeki bo phahameng le ho tšoana ha mocheso

3. Ho hanyetsa ha kutu e ntle haholo: acid, alkali, letsoai le li-reagents tsa manyolo.

4. Boima bo phahameng, bokaholimo bo kopanetsoeng, likaroloana tse ntle.

5. Bophelo bo bolelele ba tšebeletso le bo tšoarellang haholoanyane

| CVD SiC薄膜基本物理性能 Lintho tsa motheo tsa 'mele tsa CVD SiCho roala | |

| 性质 / Thepa | 典型数值 / Boleng bo Tlwaelehileng |

| 晶体结构 / Sebopeho sa Crystal | FCC mohato oa β多晶,主要為(111)取向 |

| 密度 / Ho teteana | 3.21 g/cm³ |

| 硬度 / Ho thatafala | 2500 维氏硬度 (500g mojaro) |

| 晶粒大小 / Mabele SiZe | 2 ~ 10μm |

| 纯度 / Bohloeki ba lik'hemik'hale | 99.99995% |

| 热容 / Bokhoni ba mocheso | 640 J·kg-1·K-1 |

| 升华温度 / Sublimation Mocheso | 2700 ℃ |

| 抗弯强度 / Flexural Matla | 415 MPa RT 4-ntlha |

| 杨氏模量 / Young's Modulus | 430 Gpa 4pt kobeha, 1300 ℃ |

| 导热系数 / ThermalBoikhantšo | 300Wm-1·K-1 |

| 热膨胀系数 / Katoloso ea Mocheso(CTE) | 4.5×10-6K-1 |

Re u amohela ka mofuthu hore u etele feme ea rona, ha re buisaneng ka ho eketsehileng!

-

Factory Cheap Hot China 1700 Degree Vacuum Tube...

-

Theko e Tsitsitseng ea Tlholisano China Compact Thermal O...

-

100% Original Quality High Matla Graphi...

-

Heater ea nako e telele ea SIC e koahetsoeng ka Graphite bakeng sa MOCVD ...

-

Moetsi oa Purity Graphite Rod Density Gr...

-

Feme ea OEM bakeng sa terata e tlase ea 1j79, Soft Magnetic All...