Tlhaloso:

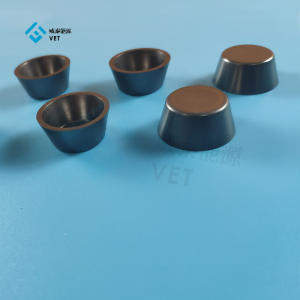

Silicon Carbide e na le thepa e ntle ea ho hanyetsa-corrosion, matla a phahameng a mochini, ts'ebetso e phahameng ea mocheso, ho itlotsa hantle ho sebelisoa e le lifahleho tsa tiiso, li-bearings le li-tubes sebakeng sa spacecraft, mochini, metallurgy, khatiso le dae, lijo, meriana, indasteri ea likoloi joalo-joalo. ho. Ha lifahleho tsa sic li kopantsoe le lifahleho tsa graphite khohlano ke e nyenyane ka ho fetisisa 'me e ka etsoa litiiso tsa mechine tse khonang ho sebetsa ka litlhoko tse phahameng ka ho fetisisa tsa ho sebetsa.

Lintho tsa Motheo tsa Silicon Carbide:

-Tekano e tlase

- High conductivity ea mocheso (haufi le aluminium)

-Ho hanyetsa mocheso o motle oa mocheso

-Bopaki ba metsi le khase

- Refractoriness e phahameng (e ka sebelisoa ho 1450 ℃ moeeng le 1800 ℃ moeeng o sa nke lehlakore)

-Ha e angoe ke kutu ebile ha e kolobise ka aluminium e qhibilihisitsoeng kapa zinc e qhibilihisitsoeng.

-Bothata bo phahameng

- Coefficient e tlase ea likhohlano

-Khanyetso ea ho senya

- E hanyetsana le li-acids tsa motheo le tse matla

- E bonolo

- Matla a phahameng a mochine

Sesebelisoa sa Silicon Carbide:

- Litiiso tsa mochini, li-bearings, li-thrust bearings, joalo-joalo

-Manonyeletso a potolohang

-Semiconductor le ho roala

-Pads Pump likarolo

-Likarolo tsa lik'hemik'hale

- Liipone bakeng sa tsamaiso ea laser ea indasteri.

- Li-reactors tse tsoelang pele, li-heaters tsa mocheso, joalo-joalo.

Sebopeho

Silicon carbide e thehoa ka litsela tse peli:

1) Sintered silicon carbide e se nang khatello

Ka mor'a hore lisebelisoa tsa silicon carbide tse se nang khatello li behoe, setšoantšo sa kristale se tlas'a microscope ea 200X se bontša hore kabo le boholo ba likristale li tšoana, 'me kristale e kholo ka ho fetisisa ha e fete 10μm.

2) Reaction sintered silicon carbide

Kamora karabelo ea sintered silicon carbide ka lik'hemik'hale e tšoara karolo e bataletseng le e boreleli ea thepa, kristale

kabo le boholo tlas'a microscope ea 200X ea mahlo li tšoana, 'me litaba tsa silicon tsa mahala ha li fete 12%.

| Theknoloji Thepa | |||

| Index | Yuniti | Boleng | |

| Lebitso la Boitsebiso | Pressureless Sintered Silicon Carbide | Reaction Sintered Silicon Carbide | |

| Sebopeho | SSiC | RBSiC | |

| Boima ba Bongata | g/cm3 | 3.15 ± 0.03 | 3 |

| Flexural Matla | MPa (kpsi) | 380(55) | 338(49) |

| Matla a Khatellang | MPa (kpsi) | 3970(560) | 1120(158) |

| Ho thatafala | Knoop | 2800 | 2700 |

| Qetello e Fetang | MPa m1/2 | 4 | 4.5 |

| Thermal Conductivity | W/mk | 120 | 95 |

| Coefficient ea Katoloso ea Thermal | 10-6/°C | 4 | 5 |

| Mocheso o khethehileng | Joule/g 0k | 0.67 | 0.8 |

| Mocheso o moholo moeeng | ℃ | 1500 | 1200 |

| Elastic modulus | GPA | 410 | 360 |

-

Flexible graphite paper Bohloeki bo phahameng ba khabone e phahameng...

-

Feme ea feme e feto-fetohang ea pampiri ea graphite...

-

Khabone ea Khalase ea Khalase ea Boleng bo Phahameng e hanyetsanang le kutu ...

-

Moetsi o fana ka boleng bo holimo ka kotloloho ...

-

PECVD terei/mojari o sebelisa carbon fiber reinfor...

-

Portable Backup Power Fuel Cell Pem Membrane El...