Mohala oa sehlahisoa oa VET Energy ha o felle feela ho li-wafers tsa silicon. Re boetse re fana ka lisebelisoa tse ngata tse fapaneng tsa semiconductor substrate, ho kenyeletsoa SiC Substrate, SOI Wafer, SiN Substrate, Epi Wafer, joalo-joalo, hammoho le lisebelisoa tse ncha tse pharalletseng tsa semiconductor tse kang Gallium Oxide Ga2O3 le AlN Wafer. Lihlahisoa tsena li ka fihlela litlhoko tsa ts'ebeliso ea bareki ba fapaneng ho lisebelisoa tsa motlakase tsa motlakase, maqhubu a seea-le-moea, li-sensor le likarolo tse ling.

Libaka tsa kopo:

•Li-circuits tse kopaneng:E le lisebelisoa tsa mantlha tsa tlhahiso e kopaneng ea potoloho, li-wafers tsa silicon tsa mofuta oa P li sebelisoa haholo lipotolohong tse fapaneng tsa mohopolo, mehopolo, jj.

•Lisebelisoa tsa motlakase:Li-wafer tsa silicon tsa mofuta oa P li ka sebelisoa ho etsa lisebelisoa tsa motlakase joalo ka li-transistors tsa motlakase le diode.

•Sensora:Li-wafers tsa silicon tsa mofuta oa P li ka sebelisoa ho etsa mefuta e fapaneng ea li-sensor, joalo ka li-sensor tsa khatello, li-sensor tsa mocheso, jj.

•Lisele tsa letsatsi:Li-wafers tsa silicon tsa mofuta oa P ke karolo ea bohlokoa ea lisele tsa letsatsi.

VET Energy e fa bareki litharollo tsa liphaephe tse ikhethileng, 'me e khona ho etsa li-wafers ka mokhoa o fapaneng oa ho hanyetsa, likahare tse fapaneng tsa oksijene, botenya bo fapaneng le litlhaloso tse ling ho latela litlhoko tse ikhethileng tsa bareki. Ntle le moo, re boetse re fana ka ts'ehetso ea botekgeniki le ts'ebeletso ea morao-rao ho thusa bareki ho rarolla mathata a fapaneng a kopaneng le ts'ebetso ea tlhahiso.

LIEKETSENG TSIETSO

*n-Pm=n-mofuta oa Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulation

| Ntho | 8-Intshi | 6-Intshi | 4-Intshi | ||

| nP | n-Pm | n-Pes | SI | SI | |

| TTV(GBIR) | ≤6um | ≤6um | |||

| Bow(GF3YFCD)-Boleng bo Felletseng | ≤15μm | ≤15μm | ≤25μm | ≤15μm | |

| Warp(GF3YFER) | ≤25μm | ≤25μm | ≤40μm | ≤25μm | |

| LTV(SBIR) -10mmx10mm | <2μm | ||||

| Wafer Edge | Beveling | ||||

SEBAKA PHETHA

*n-Pm=n-mofuta oa Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulation

| Ntho | 8-Intshi | 6-Intshi | 4-Intshi | ||

| nP | n-Pm | n-Pes | SI | SI | |

| Surface Finish | Mahlakore a mabeli a Optical Polish, Si- Face CMP | ||||

| SurfaceRoughness | (10um x 10um) Si-FaceRa≤0.2nm | (5umx5um) Si-Face Ra≤0.2nm | |||

| Li-Chips tsa Edge | Ha ho e dumellwe (bolelele le bophara≥0.5mm) | ||||

| Li-indent | Ha ho le e 'ngoe e Lumelloang | ||||

| Scratches(Si-Face) | Kty.≤5, Kakaretso | Kty.≤5, Kakaretso | Kty.≤5, Kakaretso | ||

| Mapetso | Ha ho le e 'ngoe e Lumelloang | ||||

| Kenyelletso ea Edge | 3mm | ||||

-

Solar Graphite Boat bakeng sa Pecvd

-

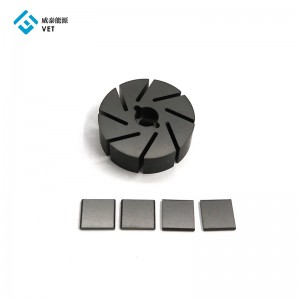

Graphite rotor bakeng sa pompo ea vacuum

-

Metsi a pholileng a 100KW hydrogen Fuel Cell Stack bakeng sa...

-

Seleng ea Mafura a Hydrogen Pem Drone Jenereithara ea Hydrogen...

-

Mofuta o tlase oa hydrogen fuel drone Sofc hydrogen gene...

-

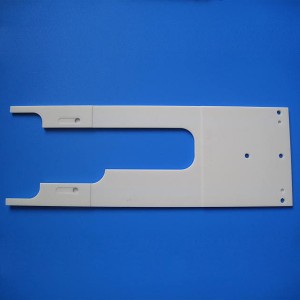

Semiconductor thepa consumables alumina cer...