Inweta mmezu nke onye zụrụ bụ ebumnuche ụlọ ọrụ anyị na-enweghị njedebe. Anyị ga-eme atụmatụ dị egwu iji nweta azịza ọhụrụ na nke kachasị mma, zute nkọwapụta gị pụrụ iche wee nye gị ndị na-ere ahịa, ndị na-ere ahịa na ndị na-ere ahịa mgbe ọ bụla maka ngwaahịa ọhụrụ Plasma kwalitere CVD Tube Furnace maka Deposition of High- Ihe nkiri siri ike dị mma, nabata ajụjụ gị, a ga-enye ọrụ kacha mma na obi zuru oke.

Inweta mmezu nke onye zụrụ bụ ebumnuche ụlọ ọrụ anyị na-enweghị njedebe. Anyị ga-eme atụmatụ dị egwu iji nweta azịza ọhụrụ na nke kachasị mma, zute nkọwapụta gị pụrụ iche wee nye gị ndị na-ere ahịa tupu ire ere na ire ere.China CVD Tube Furnace na CVD Tube Furnace Chemical Vapor Deposition, Na-esiwanye asọmpi ahịa, Na ezi obi ọrụ elu àgwà ngwaahịa na ọma kwesịrị ekwesị aha, anyị mgbe niile na-enye ndị ahịa nkwado na ihe na usoro iji nweta ogologo oge imekọ ihe ọnụ. Ibi ndụ site n'ịdị mma, mmepe site na kredit bụ nchụso ebighi ebi anyị, Anyị kwenyesiri ike na mgbe nleta gị gachara, anyị ga-abụ ndị mmekọ ogologo oge.

Ihe mejupụtara carbon / carbon(nke a na-akpọ ya "C / C ma ọ bụ CFC") bụ ụdị ihe mejupụtara nke na-adabere na carbon ma mee ka carbon fiber na ngwaahịa ya sie ike (carbon fiber preform). Ọ nwere ma inertia nke carbon na ike dị elu nke eriri carbon. Ọ nwere ezigbo n'ibu Njirimara, okpomọkụ na-eguzogide, corrosion eguzogide, esemokwu damping na thermal na eletriki conductivity àgwà.

CVD-SiCmkpuchi nwere àgwà nke edo Ọdịdị, kọmpat ihe onwunwe, elu okpomọkụ na-eguzogide, ọxịdashọn-eguzogide, elu ịdị ọcha, acid & alkali eguzogide na organic reagent, na anụ ahụ na chemical Njirimara.

N'iji ya tụnyere ihe ndị dị elu nke graphite, graphite na-amalite oxidize na 400C, nke ga-eme ka nkwụsị nke ntụ ntụ n'ihi oxidation, na-ebute mmetọ gburugburu ebe obibi na ngwaọrụ ndị dị n'akụkụ na oghere oghere, na-amụba adịghị ọcha nke gburugburu ebe obibi dị ọcha.

Agbanyeghị, mkpuchi SiC nwere ike idowe nkwụsi ike anụ ahụ na kemịkalụ na ogo 1600, a na-ejikarị ya na ụlọ ọrụ ọgbara ọhụrụ, ọkachasị na ụlọ ọrụ semiconductor.

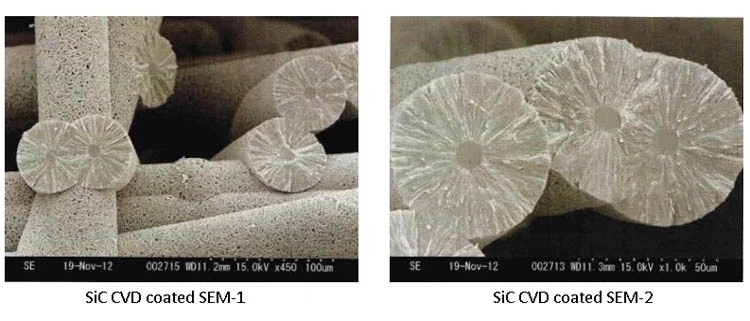

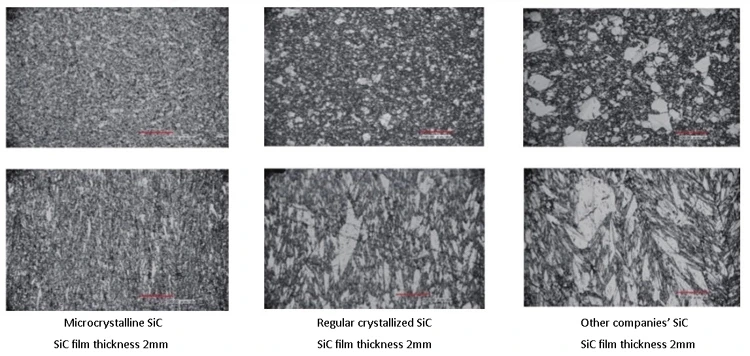

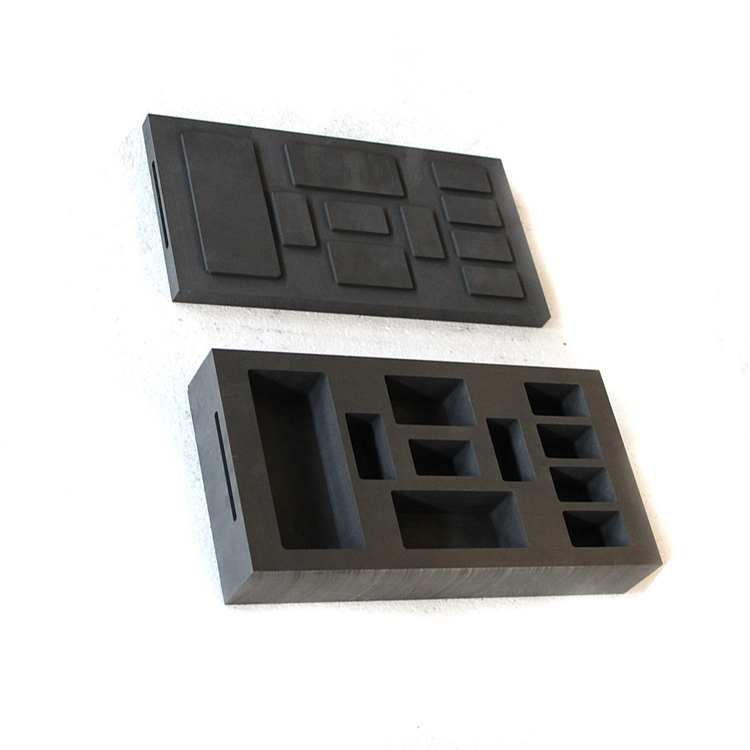

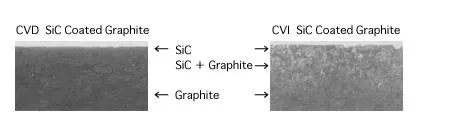

Ụlọ ọrụ anyị na-enye ọrụ usoro mkpuchi SiC site na usoro CVD n'elu graphite, ceramics na ihe ndị ọzọ, nke mere na gas pụrụ iche nwere carbon na silicon na-emeghachi omume na okpomọkụ dị elu iji nweta mkpụrụ ndụ SiC dị ọcha, ụmụ irighiri ihe ndị a na-edebe n'elu ihe ndị a na-ekpuchi, na-akpụ oyi akwa mkpuchi SIC. The SIC guzobere na-ike bonded na graphite isi, na-enye graphite isi pụrụ iche Njirimara, si otú na-eme ka elu nke graphite kọmpat, Porosity-free, elu okpomọkụ nguzogide, corrosion iguzogide na oxidation resistance.

Isi atụmatụ:

1. Nguzogide oxidation dị elu:

Nguzogide oxidation ka dị ezigbo mma mgbe okpomọkụ dị elu dị ka 1600 C.

2. Nnukwu ịdị ọcha: nke a na-eme site na ntinye ikuku kemịkalụ n'okpuru ọnọdụ chlorination dị elu.

3. Nguzogide nbibi: elu ike, kọmpat elu, ezigbo ahụ.

4. Nguzogide corrosion: acid, alkali, nnu na organic reagents.

Nkọwa bụ isi nke mkpuchi CVD-SIC:

| SiC-CVD | ||

| Njupụta | (g/cc)

| 3.21 |

| Ike mgbanwe | (Mpa)

| 470 |

| Mgbasa ọkụ ọkụ | (10-6/K) | 4

|

| Thermal conductivity | (W/mK) | 300

|