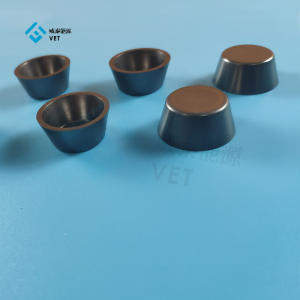

VET Energy siv ultra-siab puritysilicon carbide (SiC)tsim los ntawm chemical vapor deposition(CVD)raws li cov khoom siv rau kev loj hlobSiC siv lead ualos ntawm lub cev vapor thauj (PVT). Hauv PVT, cov khoom siv yog thauj mus rau hauv acruciblethiab sublimated mus rau lub noob siv lead ua.

Lub siab purity qhov yuav tsum tau ua kom zooSiC siv lead ua.

VET Energy tshwj xeeb hauv kev muab cov khoom loj SiC rau PVT vim tias nws muaj qhov ntom ntom dua li cov khoom me me uas tsim los ntawm kev sib xyaw ua ke ntawm Si thiab C-muaj roj. Tsis zoo li cov txheej txheem sintering los yog cov tshuaj tiv thaiv ntawm Si thiab C, nws tsis tas yuav muaj lub siab sintering rauv lossis lub sij hawm siv sintering kauj ruam hauv qhov cub loj hlob. Cov khoom loj-particle no muaj ze li ntawm evaporation tus nqi, uas txhim kho kev khiav-rau-khiav uniformity.

Taw qhia:

1. Npaj CVD-SiC thaiv qhov chaw: Ua ntej, koj yuav tsum tau npaj cov khoom zoo CVD-SiC thaiv qhov chaw, uas feem ntau yog cov purity siab thiab siab ceev. Qhov no tuaj yeem npaj tau los ntawm kev siv tshuaj vapor deposition (CVD) raws li qhov tsim nyog cov tshuaj tiv thaiv.

2. Kev npaj substrate: Xaiv ib lub substrate tsim nyog raws li lub substrate rau SiC ib tug crystal kev loj hlob. Feem ntau siv cov khoom siv substrate muaj xws li silicon carbide, silicon nitride, thiab lwm yam, uas muaj qhov zoo sib xws nrog SiC ib leeg siv lead ua.

3. Cua sov thiab sublimation: Muab CVD-SiC thaiv qhov chaw thiab substrate rau hauv qhov cub kub kub thiab muab cov sublimation tsim nyog. Sublimation txhais tau hais tias nyob rau ntawm qhov kub thiab txias, qhov thaiv qhov chaw ncaj qha hloov ntawm cov khoom mus rau lub xeev vapor, thiab tom qab ntawd rov ua dua rau ntawm qhov chaw substrate kom tsim tau ib qho siv lead ua.

4. Kev tswj qhov kub thiab txias: Thaum lub sij hawm sublimation txheej txheem, qhov kub ntawm gradient thiab kub faib yuav tsum tau tswj kom meej meej los txhawb lub sublimation ntawm lub block qhov chaw thiab kev loj hlob ntawm ib tug crystals. Kev tswj qhov kub kom tsim nyog tuaj yeem ua tiav qhov zoo tshaj plaws siv lead ua zoo thiab tus nqi loj hlob.

5. Kev tswj huab cua: Thaum lub sij hawm sublimation txheej txheem, cov tshuaj tiv thaiv huab cua kuj yuav tsum tau tswj. High-purity inert gas (xws li argon) feem ntau yog siv los ua cov pa roj carbon monoxide kom tswj tau qhov tsim nyog thiab purity thiab tiv thaiv kom tsis txhob muaj kab mob los ntawm impurities.

6. Ib leeg siv lead ua kev loj hlob: CVD-SiC thaiv qhov chaw nkag mus rau theem vapor hloov thaum lub sij hawm sublimation txheej txheem thiab recondenses ntawm lub substrate nto los tsim ib tug crystal qauv. Kev loj hlob sai ntawm SiC ib leeg muaju tuaj yeem ua tiav los ntawm qhov tsim nyog sublimation tej yam kev mob thiab kub gradient tswj.

-

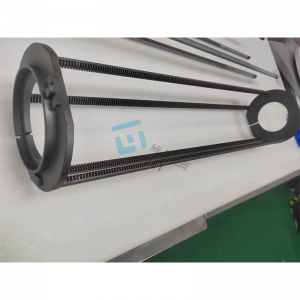

High-Quality Tantalum Carbide Tube rau SiC Crys ...

-

Corrosion-resistant High Quality Glassy Carbon ...

-

Tantalum carbide txheej: hnav-tiv taus, siab-...

-

Loj Loj Recrystallized Silicon Carbide Wafer ...

-

Custom High Purity SiC Coated Graphite rhaub H...

-

High-kev ua tau zoo tantalum carbide coated ntx...