Bayani:

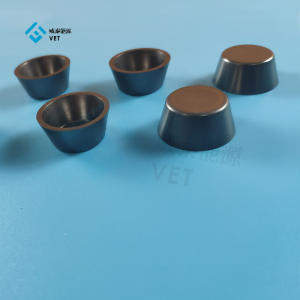

Silicon Carbide suna da kaddarorin kyakkyawan juriya-lalata, babban ƙarfin injina, haɓakar zafin jiki mai ƙarfi, mai kyau mai mai da ake amfani da shi azaman fuskokin hatimi, bearings da bututu a cikin jirgin sama, injina, ƙarfe, bugu da rini, kayan abinci, magunguna, masana'antar mota da sauransu. kan. Lokacin da aka haɗa fuskokin sic tare da fuskokin graphite gogayya ita ce mafi ƙanƙanta kuma ana iya sanya su cikin hatimin injina waɗanda ke da ikon yin aiki cikin buƙatun aiki mafi girma.

Silicon Carbide Basic Properties:

-Ƙarancin yawa

- High thermal conductivity (kusa da aluminum)

-Kyakkyawan juriyar girgiza zafin zafi

-Tabbatar ruwa da gas

-High refractoriness (za a iya amfani da a 1450 ℃ a cikin iska da kuma 1800 ℃ a tsaka tsaki yanayi)

-Ba a shafe shi da lalata kuma kar a jika da narkakken aluminum ko narkar da zinc

-Babban taurin

- Low gogayya coefficient

-Abrasion juriya

-Ya tsayayya da asali kuma mai ƙarfi acid

- mai goge baki

-High inji ƙarfi

Aikace-aikacen Silicon Carbide:

-Mechanical like, bearings, tura bearings, da dai sauransu

-Juyawan haɗin gwiwa

-Semiconductor da shafi

-Pads Pump abubuwan

- Abubuwan sinadaran

-Madubi don tsarin Laser masana'antu.

- Reactor mai ci gaba da gudana, masu musayar zafi, da sauransu.

Siffar

Silicon carbide yana samuwa ta hanyoyi biyu:

1) Silicon carbide mara ƙarfi mara ƙarfi

Bayan abin da ba shi da matsi na silicon carbide an yi shi, zanen lokaci na kristal a ƙarƙashin 200X microscope na gani yana nuna cewa rarrabawa da girman lu'ulu'u iri ɗaya ne, kuma mafi girman crystal bai wuce 10μm ba.

2) Reaction sintered silicon carbide

Bayan abun da ya faru sintered silicon carbide chemically yana kula da sashin layi mai santsi da santsi na kayan, crystal

Rarraba da girma a ƙarƙashin microscope na gani na 200X iri ɗaya ne, kuma abun cikin siliki na kyauta bai wuce 12% ba.

| Abubuwan Fasaha | |||

| Fihirisa | Naúrar | Daraja | |

| Sunan Abu | Sintered Silicon Carbide mara matsi | Reaction Sintered Silicon Carbide | |

| Abun ciki | SSiC | RBSiC | |

| Yawan yawa | g/cm3 | 3.15 ± 0.03 | 3 |

| Ƙarfin Flexural | MPa (kpsi) | 380(55) | 338 (49) |

| Ƙarfin Ƙarfi | MPa (kpsi) | 3970(560) | 1120 (158) |

| Tauri | Knoop | 2800 | 2700 |

| Breaking Tenacity | MPa m1/2 | 4 | 4.5 |

| Thermal Conductivity | W/mk | 120 | 95 |

| Coefficient na Thermal Expansion | 10-6/C | 4 | 5 |

| Takamaiman Zafi | Joule/g 0k | 0.67 | 0.8 |

| Matsakaicin zafin jiki a cikin iska | ℃ | 1500 | 1200 |

| Modul na roba | Gpa | 410 | 360 |

-

M graphite takarda High tsarki high carbon ...

-

Factory wadata m graphite takarda artifici ...

-

Carbon Carbon Gilashi Mai Kyau Mai Jurewa Lalacewa...

-

Mai sana'anta kai tsaye yana ba da inganci mai inganci ...

-

PECVD tire/danko mai amfani da carbon fiber ƙarfafa ...

-

Ƙarfin Ajiyayyen Ƙarfin Man Fetur Cell Pem Membrane El...