Iipropati ze-silicon carbide ehlaziyiweyo

I-silicon carbide ehlaziyiweyo (i-R-SiC) yinto ephezulu yokusebenza enobunzima besibini kuphela kwidayimane, eyenziwe kubushushu obuphezulu obungaphezulu kwe-2000 ℃. Igcina iipropathi ezininzi ezigqwesileyo ze-SiC, ezinje ngamandla obushushu obuphezulu, ukuxhathisa okuqinileyo kwe-corrosion, ukuxhathisa okugqwesileyo kwe-oxidation, ukuchasana kakuhle nokothuka kwe-thermal njalo njalo.

● Iimpawu ezigqwesileyo zoomatshini. I-silicon carbide ehlaziyiweyo inamandla aphezulu kunye nokuqina kune-carbon fiber, ukuchasana kweempembelelo eziphezulu, kunokudlala ukusebenza kakuhle kwiindawo eziphakamileyo zokushisa, kunokudlala ukusebenza kakuhle kokulinganisa kwiimeko ezahlukeneyo. Ukongezelela, ibuye ibe nokuguquguquka okulungileyo kwaye ayonakaliswa lula ngokuzolula kunye nokugoba, okuphucula kakhulu ukusebenza kwayo.

● Ukumelana ne-corrosion ephezulu. I-silicon carbide ehlaziyiweyo inokumelana nokugqwala okuphezulu kwiindidi ezahlukeneyo zeendaba, inokuthintela ukukhukuliseka kweentlobo ezahlukeneyo zeendaba ezitshabalalisayo, inokugcina iipropathi zayo zemishini ixesha elide, inokuqina okuqinileyo, ukuze ibe nobomi obude benkonzo. Ukongezelela, ikwanayo nokuzinza okuhle kwe-thermal, iyakwazi ukulungelelanisa uluhlu oluthile lokutshintsha kweqondo lokushisa, ukuphucula umphumo wesicelo sayo.

● Ukuhlambalaza akufihli. Ngenxa yokuba inkqubo ye-sintering ayinciphisi, akukho xinzelelo olushiyekileyo luya kubangela ukuguqulwa okanye ukuqhekeka kwemveliso, kunye neengxenye ezinemilo enzima kunye nokuchaneka okuphezulu kunokulungiswa.

| 重结晶碳化硅物理特性 Iimpawu ezibonakalayo zeRecrystallized Silicon Carbide | |

| 性质 / Ipropati | 典型数值 / Ixabiso eliqhelekileyo |

| 使用温度/ Ubushushu bokusebenza (°C) | 1600°C (neoksijini), 1700°C (ukunciphisa okusingqongileyo) |

| SiC含量/ Umxholo weSiC | > 99.96% |

| 自由Si含量/ Isiqulatho sasimahla seSi | < 0.1% |

| 体积密度/Unizi lolwapho kuyiwa khona | 2.60-2.70 g / cm3 |

| 气孔率/ I-porosity ebonakalayo | < 16% |

| 抗压强度/ Amandla oxinzelelo | > 600MPa |

| 常温抗弯强度/Amandla okugoba okubandayo | 80-90 MPa (20°C) |

| 高温抗弯强度Amandla okugoba ashushu | 90-100 MPa (1400°C) |

| 热膨胀系数/ Ukwandiswa kweThermal @1500°C | 4.70 10-6/°C |

| 导热系数/I-Thermal conductivity @1200°C | 23W/m•K |

| 杨氏模量/ Imodyuli yeelastiki | 240 GPA |

| 抗热震性/ Ukuxhathisa ukothuka kobushushu | Ulunge kakhulu |

Amandla eVET yi iumenzi wokwenyani weemveliso ezenziwe ngokwezifiso zegraphite kunye nesilicon carbide ene-CVD coating,inokubonelelaezahlukeneyoiindawo ezilungiselelwe i-semiconductor kunye ne-photovoltaic industry. OIqela le-ur lobuchwephesha livela kumaziko aphezulu ophando lwasekhaya, linokubonelela ngezisombululo zemathiriyeli yobuchwepheshayeyakho.

Siqhubeka siphuhlisa iinkqubo eziphambili ukubonelela ngemathiriyeli ephezulu kakhulu,kwayebaye benza iteknoloji ekhethekileyo yelungelo elilodwa lomenzi wechiza, enokwenza iqhina phakathi kwengubo kunye ne-substrate ibe ngqongqo kwaye ingabikho lula kwi-deachment.

| CVD SiC薄膜基本物理性能 Iimpawu ezisisiseko ze-CVD SiCukutyabeka | |

| 性质 / Ipropati | 典型数值 / Ixabiso eliqhelekileyo |

| 晶体结构 / Ulwakhiwo lweCrystal | iFCC β isigaba多晶,主要為(111)取向 |

| 密度 / Ubuninzi | 3.21 g/cm³ |

| 硬度 / Ukuqina | 2500 维氏硬度 (500g umthwalo) |

| 晶粒大小 / Iinkozo uSiZe | 2 ~ 10μm |

| 纯度 / Ukucoceka kwemichiza | 99.99995% |

| 热容 / Umthamo wobushushu | 640 J·kg-1·K-1 |

| 升华温度 / Iqondo lobushushu elisezantsi | 2700℃ |

| 抗弯强度 / Amandla e-Flexural | 415 MPa RT 4-point |

| 杨氏模量 / Imodyuli yabaselula | 430 Gpa 4pt bend, 1300℃ |

| 导热系数 / ThermalUkuqhuba | 300Wm-1·K-1 |

| 热膨胀系数 / Ukwandiswa kweThermal(CTE) | 4.5×10-6K-1 |

Wamkelekile ngokufudumeleyo ukuba undwendwele umzi-mveliso wethu, makhe sibenengxoxo eyongezelelekileyo!

-

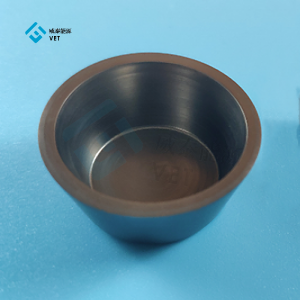

Uzinzo lobushushu obuphezulu beglasi yekhabhoni crucible

-

Ukumelana nokuNxitywa okuLungileyo kunye noKuxhathisa ukuMhlwa T...

-

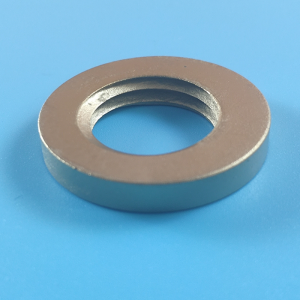

I-TaC Coated Graphite Ring

-

I-Tantalum Carbide (TaC) uMvelisi weNgqungquthela kwi ...

-

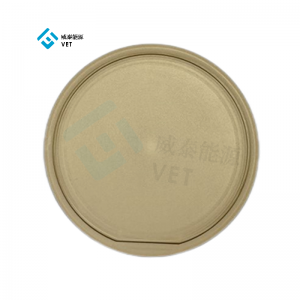

Ubungakanani oMkhulu obuphinde buphinde bufakwe kwiSilicon Carbide Wafer...

-

Umbhobho oPhezulu weTantalum Carbide weSiC Ukhala...