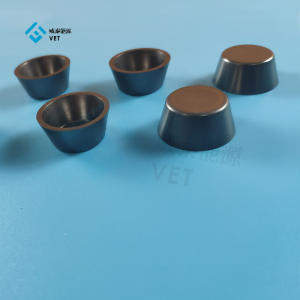

I-VET Amandla isebenzisa ubunyulu obuphezulu kakhului-silicon carbide (SiC)yenziwe yikhemikhali yokubeka umphunga(CVD)njengomthombo wemathiriyeli yokukhulaIikristale zeSiCngothutho lomoya womzimba (PVT). Kwi-PVT, i-source material ilayishwa kwi-ai-cruciblekwaye ifakwe kwikristale yembewu.

Umthombo wococeko oluphezulu uyafuneka ukwenza umgangatho ophezuluIikristale zeSiC.

I-VET Energy igxile ekuboneleleni ngamasuntswana amasuntswana e-SiC ye-PVT ngenxa yokuba inoxinano oluphezulu kunesixhobo esinesuntswana elincinci elenziwe kukutsha okuzenzekelayo kwe-Si kunye neegesi ezine-C. Ngokungafaniyo ne-slid-phase sintering okanye i-reaction ye-Si kunye ne-C, ayifuni isithando somlilo esizinikezeleyo okanye inyathelo elithatha ixesha lokutshisa kwisithando somlilo. Esi sisixhobo esinamasuntswana amakhulu sinesantya esiphantse sibe ngumphunga, esiphucula ukufana kwe-run-to-run.

Intshayelelo:

1. Lungiselela umthombo webhloko ye-CVD-SiC: Okokuqala, kufuneka ulungiselele umthombo webhloko we-CVD-SiC ophezulu, odla ngokucoceka okuphezulu kunye nokuxinana okuphezulu. Oku kunokulungiswa nge-chemical vapor deposition (CVD) indlela phantsi kweemeko ezifanelekileyo zokusabela.

2. Ukulungiswa kweSubstrate: Khetha i-substrate efanelekileyo njenge-substrate ye-SiC enye yokukhula kwekristale. Izinto ezisetyenziswa ngokuqhelekileyo kwi-substrate ziquka i-silicon carbide, i-silicon nitride, njl., ezinomdlalo olungileyo kunye ne-SiC eyodwa yekristale ekhulayo.

3. Ukufudumeza kunye ne-sublimation: Beka umthombo webhloko ye-CVD-SiC kunye ne-substrate kwisithando somlilo esiphezulu kwaye unikeze iimeko ezifanelekileyo ze-sublimation. I-Sublimation ithetha ukuba kwiqondo lokushisa eliphezulu, umthombo webhloko utshintsha ngokuthe ngqo ukusuka kwisigxina ukuya kwisimo somoya, kwaye uphinde udibanise kwi-substrate surface ukuze wenze i-crystal eyodwa.

4. Ukulawulwa kweqondo lokushisa: Ngexesha lenkqubo ye-sublimation, i-gradient yeqondo lokushisa kunye nokusabalalisa ukushisa kufuneka kulawulwe ngokuchanekileyo ukukhuthaza i-sublimation yomthombo webhloko kunye nokukhula kweekristale enye. Ukulawulwa kobushushu obufanelekileyo kunokufikelela umgangatho ofanelekileyo wekristale kunye nesantya sokukhula.

5. Ulawulo lwe-Atmosphere: Ngexesha lenkqubo ye-sublimation, umoya wokuphendula nawo kufuneka ulawulwe. Igesi ye-inert ecocekileyo ephezulu (efana ne-argon) idla ngokusetyenziswa njengegesi yokuthwala ukugcina uxinzelelo olufanelekileyo kunye nokucoceka kunye nokukhusela ukungcoliswa kokungcola.

6. Ukukhula kwekristale enye: Umthombo webhlokhi ye-CVD-SiC ufumana inguqu yesigaba somphunga ngexesha lenkqubo ye-sublimation kwaye iphinda ibuyele kwi-substrate surface ukwenza isakhiwo se-crystal esisodwa. Ukukhula okukhawulezayo kweekristale enye ye-SiC kunokufezekiswa ngeemeko ezifanelekileyo ze-sublimation kunye nolawulo lweqondo lobushushu.

-

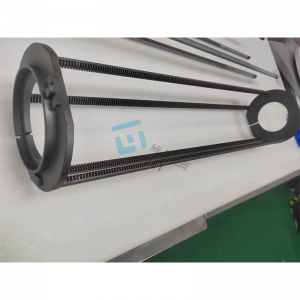

Umbhobho oPhezulu weTantalum Carbide weSiC Ukhala...

-

Ikhabhoni yeglasi eneglasi ekwaziyo ukumelana nokutyiwa ...

-

I-Tantalum carbide iyagquma: ukumelana nokunxiba, okuphezulu-...

-

Ubungakanani oMkhulu obuphinde buphinde bufakwe kwiSilicon Carbide Wafer...

-

Isifudumezi Sesifudumezi seGraphite seSiko esiPhezulu seSiC esigqunywe ...

-

Ukusebenza okuphezulu kwetantalum carbide egqunywe ngamathambo...