Ba SinteredSilicon Carbide (SiC)kristale/Sekepe sa Wafere etselitsoe litlhoko tse matla tsa indasteri ea semiconductor le microelectronics. E fana ka sethala se sireletsehileng bakeng sa ho sebetsana le likristale tsa silicon le li-wafers nakong ea ts'ebetso e phahameng ea mocheso, ho netefatsa hore botšepehi ba bona le bohloeki li bolokiloe hohle.

Likarolo tsa Bohlokoa

- Thermal Stability e ikhethang: E khona ho mamella mocheso ho fihlela ho 1600 ° C, e loketseng bakeng sa lits'ebetso tse hlokang taolo e nepahetseng ea mocheso.

- Khanyetso e Phahameng ea Lik'hemik'hale: E hanyetsana le lik'hemik'hale le likhase tse senyang haholo, e fana ka nako e telele libakeng tse thata tsa ho sebetsa.

- Matla a Matla a Mechini: E boloka botšepehi ba sebopeho tlas'a khatello e phahameng ea maikutlo, ho fokotsa monyetla oa ho senyeha kapa ho senyeha.

- Keketso e Nyenyane ea Thermal: E etselitsoe ho fokotsa kotsi ea ho ts'oha ha mocheso le ho phatloha, e fana ka ts'ebetso e tšepahalang ka tšebeliso e telele.

- Precision Manufacturing: E entsoe ka nepo e phahameng ho fihlela litlhoko tse ikhethileng tsa ts'ebetso le ho amohela boholo bo fapaneng ba kristale le liphaphatha.

Lisebelisoa

• Ho sebetsa ka semiconductor wafer

• tlhahiso ea LED

• Ho hlahisa lisele tsa photovoltaic

• Mekhoa ea ho beha mouoane oa lik'hemik'hale (CVD).

• Patlisiso le nts'etsopele ea mahlale a lintho tse bonahalang

| 烧结碳化硅物理特性 Lintho tse bonahalang tsaSintered/SiliconCarbide | |

| 性质 / Thepa | 典型数值 / Boleng bo Tlwaelehileng |

| 化学成分 / Lik'hemik'haleSebopeho | SiC>95%, Si<5% |

| 体积密度 / Boima ba Bongata | >3.07 g/cm³ |

| 显气孔率/ Porosity e bonahalang porosity e bonahalang | <0.1% |

| 常温抗弯强度/ Modulus ea ho phatloha ho 20℃ | 270 MPa |

| 高温抗弯强度/ Modulus ea ho phatloha ho 1200℃ | 290MPa |

| 硬度/ Ho thatafala ha 20℃ | 2400 Kg/mm² |

| 断裂韧性/ Ho robeha ho thata ho 20% | 3.3MPa · m1/2 |

| 导热系数/ Thermal Conductivity ho 1200℃ | 45w/m .K |

| 热膨胀系数/ Katoloso ea mocheso ho 20-1200℃ | 4.51 × 10-6/℃ |

| 最高工作温度/ Max.mocheso o sebetsang | 1400 ℃ |

| 热震稳定性/ Ho hanyetsa mocheso oa mocheso ho 1200 ℃ | E ntle |

Hobaneng re Khetha Seketsoana sa Rōna sa Sintered Silicon Carbide (SiC) Crystal/Wafer?

Ho khetha SiC Crystal/Wafer Boat ea rona ho bolela ho khetha ho ts'epahala, ho sebetsa hantle le ho phela nako e telele. Sekepe se seng le se seng se etsa mehato e tiileng ea taolo ea boleng ho netefatsa hore se fihlella maemo a holimo ka ho fetisisa a indasteri. Sehlahisoa sena ha se matlafatse tšireletseho le tlhahiso ea ts'ebetso ea hau ea tlhahiso feela empa se boetse se tiisa boleng bo tsitsitseng ba likristale tsa hau tsa silicon le li-wafers. Ka SiC Crystal/Wafer Boat ea rona, o ka tšepa tharollo e tšehetsang bokhabane ba hau ba ts'ebetso.

-

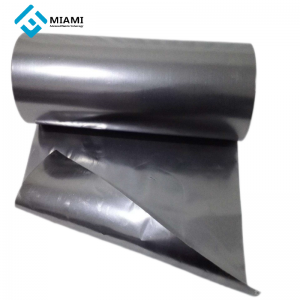

Pampiri e tloahelehileng ea graphite ea pyrolytic e atolosoa ...

-

Fuel Cell 1000w 24v Drone Hydrogen Fuel Cell Kit

-

RTP/RTA SiC Coating Carrier bakeng sa MOCVD Epitaxial...

-

Cell ea Mafura ea Hydrogen e nang le botsitso bo botle le bo phahameng ...

-

2kw Nyenyane Hydrogen Fuel Cell Hydrogen Engine 25...

-

Carbon Graphite Block, graph e hatellang ea isostatic...