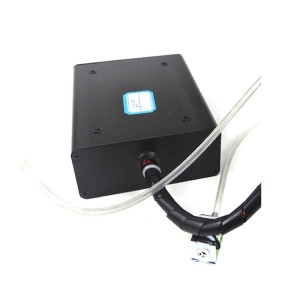

vet-china e hlahisa sekepe sa morao-rao sa Contiguous Wafer Boat se etselitsoeng moloko o latelang oa tlhahiso ea semiconductor. Seketsoana sena se entsoeng ka makhethe se fana ka ho nepahala ho ke keng ha bapisoa ho ts'oaroang ha li-wafer, ho netefatsa ts'ebetso e se nang moeli le ho fokotsa haholo kotsi ea tšenyo nakong ea ts'ebetso.

E hahiloe ka thepa ea boleng bo holimo, Contiguous Wafer Boat e ithorisa ka botsitso bo botle ba mocheso le khanyetso e ikhethang ea lik'hemik'hale, e etsa hore e be e loketseng maemo a phahameng a mocheso le tikoloho e thata ea lik'hemik'hale. Moralo oa eona o mocha o netefatsa hore li-wafers li ts'oaroa ka mokhoa o sireletsehileng 'me li tsamaellana hantle, ho ntlafatsa ts'ebetso le ho eketsa ts'ebetso ea tlhahiso.

Seketsoana sena sa li-wafer se hahelletsoeng hantle se etselitsoe ho fihlela litlhoko tse batloang ke masela a semiconductor a sejoale-joale, a ts'ehetsa boholo le tlhophiso e fapaneng. Ka ho kenyelletsa Contiguous Wafer Boat ho tloha vet-china moleng oa hau oa tlhahiso, o ka lebella ts'ebetso e ntlafetseng, nako e fokotsehileng ea nako, le litefiso tse eketsehileng tsa lihlahisoa.

Eba le phapang pakeng tsa boitlamo ba vet-china ho boleng le boqapi, ho fana ka lihlahisoa tse sutumetsang meeli ea tlhahiso ea semiconductor. Khetha Seketsoana sa Contiguous Wafer 'me u phahamisetse bokhoni ba hau ba ho sebetsa ka liphaephe ho fihla bophahamong bo bocha.

Thepa ea recrystallized silicon carbide

Recrystallized silicon carbide (R-SiC) ke sesebelisoa se sebetsang hantle se nang le boima ba bobeli ho daemane, se entsoeng ka mocheso o phahameng ka holimo ho 2000 ℃. E na le lisebelisoa tse ngata tse ntle tsa SiC, joalo ka matla a mocheso o phahameng, khanyetso e matla ea kutu, khanyetso e ntle ea oxidation, ho hanyetsa mocheso o motle joalo-joalo.

● Mekhoa e metle ea ho sebetsa. Recrystallized silicon carbide e na le matla a phahameng le ho satalla ho feta carbon fiber, khanyetso e matla, e ka bapala ts'ebetso e ntle maemong a mocheso o feteletseng, e ka bapala ts'ebetso e ntle ea ho hanyetsa maemong a fapaneng. Ho phaella moo, e boetse e na le ho feto-fetoha ha maemo hantle 'me ha e senyehe habonolo ka ho otlolla le ho koba, e leng ho ntlafatsang haholo ts'ebetso ea eona.

● Ho hanyetsa ho bola ho hoholo. Recrystallized silicon carbide e na le khanyetso e phahameng ea kutu ho mefuta e fapaneng ea mecha ea litaba, e ka thibela khoholeho ea mefuta e mengata ea mecha ea phatlalatso e senyang, e ka boloka thepa ea eona ea mechine ka nako e telele, e na le ho khomarela ka matla, e le hore e be le bophelo bo bolelele ba tšebeletso. Ho phaella moo, e boetse e na le botsitso bo botle ba mocheso, e ka ikamahanya le mefuta e itseng ea liphetoho tsa mocheso, e ntlafatsa phello ea eona ea kopo.

● Sintering ha e fokotsehe. Hobane ts'ebetso ea sintering ha e fokotsehe, ha ho khatello e setseng e tla baka deformation kapa ho phunyeha ha sehlahisoa, 'me likarolo tse nang le libopeho tse rarahaneng le ho nepahala ho phahameng li ka lokisoa.

| 重结晶碳化硅物理特性 Thepa ea 'mele ea Recrystallized Silicon Carbide | |

| 性质 / Thepa | 典型数值 / Boleng bo Tlwaelehileng |

| 使用温度/ Mocheso oa ho sebetsa (°C) | 1600°C (ka oksijene), 1700°C (ho fokotsa tikoloho) |

| SiC含量/ Likahare tsa SiC | 99.96% |

| 自由Si含量/ Likahare tsa Si mahala | <0.1% |

| 体积密度/Boima ba bongata | 2.60-2.70 g/cm3 |

| 气孔率/ Porosity e bonahalang | <16% |

| 抗压强度/ Matla a ho hatella | > 600MPa |

| 常温抗弯强度/Matla a ho kobeha a batang | 80-90 MPa (20°C) |

| 高温抗弯强度Matla a ho kobeha a chesang | 90-100 MPa (1400°C) |

| 热膨胀系数/ Katoloso ea mocheso @1500°C | 4.70 10-6/°C |

| 导热系数/Thermal conductivity @1200°C | 23W/m•K |

| 杨氏模量/ Modulase wa mothapo | 240 GPA |

| 抗热震性/ Ho hanyetsa mocheso oa mocheso | E ntle haholo |

VET Energy ke themoetsi oa 'nete oa lihlahisoa tse ikhethileng tsa graphite le silicon carbide tse nang le CVD coating,e ka fana katse fapa-fapanenglikarolo tse ikhethileng bakeng sa indasteri ea semiconductor le photovoltaic. OSehlopha sa ur sa tekheniki se tsoa litsing tse phahameng tsa lipatlisiso tsa lapeng, se ka fana ka litharollo tsa lisebelisoa tse ngata tsa litsebimolemong oa hau.

Re tsoela pele ho nts'etsapele lits'ebetso tse tsoetseng pele ho fana ka lisebelisoa tse tsoetseng pele,leba sebelitse theknoloji e ikhethileng e nang le tokelo ea molao, e ka etsang hore maqhama pakeng tsa ho roala le substrate e be thata le ho se khone ho arohana.

| CVD SiC薄膜基本物理性能 Lintho tsa motheo tsa 'mele tsa CVD SiCho roala | |

| 性质 / Thepa | 典型数值 / Boleng bo Tlwaelehileng |

| 晶体结构 / Sebopeho sa Crystal | FCC mohato oa β多晶,主要為(111)取向 |

| 密度 / Ho teteana | 3.21 g/cm³ |

| 硬度 / Ho thatafala | 2500 维氏硬度 (500g mojaro) |

| 晶粒大小 / Mabele SiZe | 2 ~ 10μm |

| 纯度 / Bohloeki ba lik'hemik'hale | 99.99995% |

| 热容 / Bokhoni ba mocheso | 640 J·kg-1·K-1 |

| 升华温度 / Sublimation Mocheso | 2700 ℃ |

| 抗弯强度 / Flexural Matla | 415 MPa RT 4-ntlha |

| 杨氏模量 / Young's Modulus | 430 Gpa 4pt kobeha, 1300 ℃ |

| 导热系数 / ThermalBoikhantšo | 300Wm-1·K-1 |

| 热膨胀系数 / Katoloso ea Mocheso(CTE) | 4.5×10-6K-1 |

Re u amohela ka mofuthu hore u etele feme ea rona, ha re buisaneng ka ho eketsehileng!