Thepa ea recrystallized silicon carbide

Recrystallized silicon carbide (R-SiC) ke sesebelisoa se sebetsang hantle se nang le boima ba bobeli ho daemane, se entsoeng ka mocheso o phahameng ka holimo ho 2000 ℃. E na le lisebelisoa tse ngata tse ntle tsa SiC, joalo ka matla a mocheso o phahameng, khanyetso e matla ea kutu, khanyetso e ntle ea oxidation, ho hanyetsa mocheso o motle joalo-joalo.

● Mekhoa e metle ea ho sebetsa. Recrystallized silicon carbide e na le matla a phahameng le ho satalla ho feta carbon fiber, khanyetso e matla, e ka bapala ts'ebetso e ntle maemong a mocheso o feteletseng, e ka bapala ts'ebetso e ntle ea ho hanyetsa maemong a fapaneng. Ho phaella moo, e boetse e na le ho feto-fetoha ha maemo hantle 'me ha e senyehe habonolo ka ho otlolla le ho koba, e leng ho ntlafatsang haholo ts'ebetso ea eona.

● Ho hanyetsa ho bola ho hoholo. Recrystallized silicon carbide e na le khanyetso e phahameng ea kutu ho mefuta e fapaneng ea mecha ea litaba, e ka thibela khoholeho ea mefuta e mengata ea mecha ea phatlalatso e senyang, e ka boloka thepa ea eona ea mechine ka nako e telele, e na le ho khomarela ka matla, e le hore e be le bophelo bo bolelele ba tšebeletso. Ho phaella moo, e boetse e na le botsitso bo botle ba mocheso, e ka ikamahanya le mefuta e itseng ea liphetoho tsa mocheso, e ntlafatsa phello ea eona ea kopo.

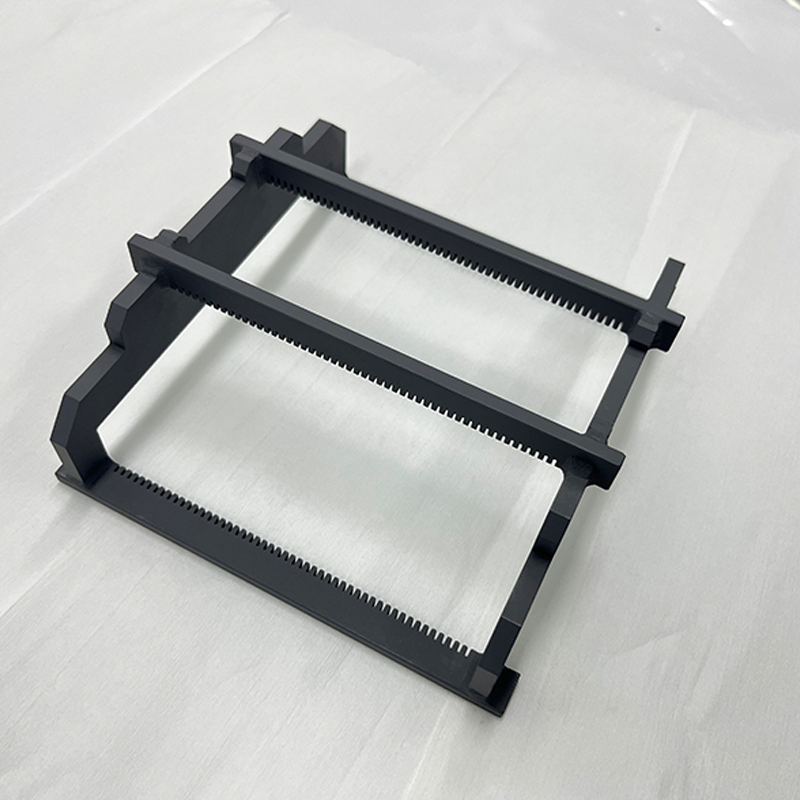

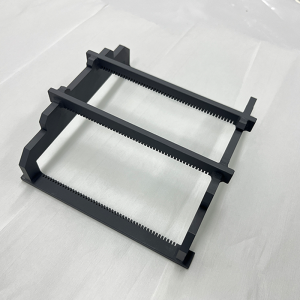

● Sintering ha e fokotsehe. Hobane ts'ebetso ea sintering ha e fokotsehe, ha ho khatello e setseng e tla baka deformation kapa ho phunyeha ha sehlahisoa, 'me likarolo tse nang le libopeho tse rarahaneng le ho nepahala ho phahameng li ka lokisoa.

| 重结晶碳化硅物理特性 Thepa ea 'mele ea Recrystallized Silicon Carbide | |

| 性质 / Thepa | 典型数值 / Boleng bo Tlwaelehileng |

| 使用温度/ Mocheso oa ho sebetsa (°C) | 1600°C (ka oksijene), 1700°C (ho fokotsa tikoloho) |

| SiC含量/ Likahare tsa SiC | 99.96% |

| 自由Si含量/ Likahare tsa Si mahala | <0.1% |

| 体积密度/Boima ba bongata | 2.60-2.70 g/cm3 |

| 气孔率/ Porosity e bonahalang | <16% |

| 抗压强度/ Matla a ho hatella | > 600MPa |

| 常温抗弯强度/Matla a ho kobeha a batang | 80-90 MPa (20°C) |

| 高温抗弯强度Matla a ho kobeha a chesang | 90-100 MPa (1400°C) |

| 热膨胀系数/ Katoloso ea mocheso @1500°C | 4.70 10-6/°C |

| 导热系数/Thermal conductivity @1200°C | 23W/m•K |

| 杨氏模量/ Modulase wa mothapo | 240 GPA |

| 抗热震性/ Ho hanyetsa mocheso oa mocheso | E ntle haholo |

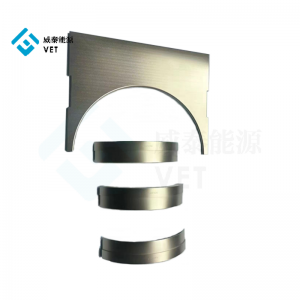

VET Energy ke moetsi oa 'nete oa lihlahisoa tse ikhethileng tsa graphite le silicon carbide tse nang le CVD coating, e ka fanang ka likarolo tse fapaneng tse ikhethileng bakeng sa indasteri ea semiconductor le photovoltaic. Sehlopha sa rona sa tekheniki se tsoa litsing tse phahameng tsa lipatlisiso tsa lapeng, se ka u fa litharollo tsa lisebelisoa tse eketsehileng bakeng sa hau.

Re ntse re tsoela pele ho nts'etsapele lits'ebetso tse tsoetseng pele ho fana ka lisebelisoa tse tsoetseng pele, 'me re entse theknoloji e ikhethileng e nang le tokelo ea molao, e ka etsang hore maqhama lipakeng tsa pente le substrate e tiee le hore e se ke ea oela habonolo.

Re u amohela ka mofuthu hore u etele feme ea rona, ha re buisaneng ka ho eketsehileng!

-

Mehele ea Karolo ea Graphite e nang le Tantalum Carbide Co...

-

Bohloeki bo Phahameng bo Tiileng ba CVD SiC Bongata bo nang le Graphite Base

-

Lesale la tataiso la graphite le koahetsoeng ke TaC

-

Khalase e Matla e Phahameng ea Khalase e Kentsoeng ka Khabone ea Matla a Phahameng Bakeng sa Tee e Phahameng...

-

Custom High Purity SiC Coated Graphite Heater H...

-

MOCVD Graphite Carrier e nang le Coating ea CVD SiC