Tamarta VET waxay isticmaashaa nadiif aad u sarreeyaSilicon carbide (SiC)ay samaysay uumiga kiimikada(CVD)sida alaabta isha ee koritaankaSiC crystalsGaadiidka uumiga jirka (PVT). Gudaha PVT, agabka isha waxaa lagu shubaa acufanoo lagu hoos dulsaaray crystal abuurka.

Isha nadiifka ah ee sare ayaa loo baahan yahay si loo soo saaro tayo sare lehSiC crystals.

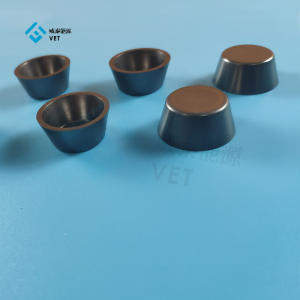

Tamarta VET waxay ku takhasustay bixinta SiC qayb weyn oo loogu talagalay PVT sababtoo ah waxay leedahay cufnaanta ka sareysa walxaha walxaha yar yar ee ay sameeyeen gubashada degdega ah ee Si iyo gaasaska ka kooban C. Si ka duwan wejiga adag ee jilbiska ama falcelinta Si iyo C, uma baahna foorno qallafsan oo u go'an ama tallaabo waqti-qaadasho ah oo foornada koritaanka ah. Walxahaan waaweyni waxa ay leeyihiin heer uumi-bax joogto ah oo ku dhow, kaas oo wanaajinaya labbiska orodka-la-socod.

Hordhac:

1. U diyaari CVD-SiC block il: Marka hore, waxaad u baahan tahay inaad diyaariso il-xidhka CVD-SiC tayo sare leh, kaas oo inta badan ah nadiif sare iyo cufnaan sare. Tan waxaa lagu diyaarin karaa habka uumiga kiimikada (CVD) ee hoos yimaada xaaladaha falcelinta habboon.

2. Diyaarinta substrate: Dooro substrate ku habboon sida substrate-ka SiC kobaca crystal-ka. Qalabka substrate-ka sida caadiga ah loo isticmaalo waxaa ka mid ah silikoon carbide, silicon nitride, iwm., kuwaas oo si fiican ula mid ah kiristaalka SiC ee sii kordhaya.

3. Kululaynta iyo sublimation: Dhig CVD-SiC isha block iyo substrate foorno heerkul sare oo bixi xaaladaha sublimation habboon. Sublimation waxay ka dhigan tahay in heerkulka sare, isha xannibaadda ay si toos ah uga beddesho xaalad adag oo uumiga, ka dibna dib-u-cusbooneysii dusha sare ee substrate si uu u sameeyo hal crystal.

4. Xakamaynta heerkulka: Inta lagu jiro habka sublimation, heerkulka heerkulka iyo qaybinta heerkulku waxay u baahan yihiin in si sax ah loo xakameeyo si kor loogu qaado sublimation ee isha block iyo koritaanka kiristaalo hal. Xakamaynta heerkulka ku habboon waxay gaari kartaa tayada kristanta ugu fiican iyo heerka koritaanka.

5. Xakamaynta jawiga: Inta lagu jiro habka sublimation, jawiga falcelinta sidoo kale wuxuu u baahan yahay in la xakameeyo. Gaaska aan nadiifka ahayn ee nadiifka ah (sida argon) ayaa inta badan loo isticmaalaa sidii gaas qaade si loo ilaaliyo cadaadiska ku habboon iyo nadiifnimada loogana hortago wasakhowga wasakhda.

6. Kobaca kareemka kali ah: Ilaha xannibaadda CVD-SiC wuxuu maraa marxaladda uumiga inta lagu jiro habka sublimation-ka oo dib-u-cusbooneysii dusha sare ee substrate si uu u sameeyo qaab dhismeed quraarad ah. Kobaca degdega ah ee kiristaalo kaliya ee SiC waxa lagu gaadhi karaa xaaladaha sublimation ee habboon iyo xakamaynta heerkulka heerkulka.

-

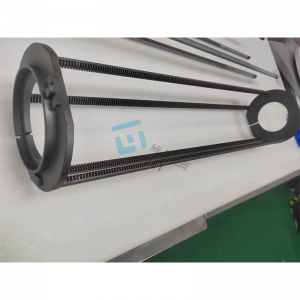

Tantalum Carbide Tube tayo sare leh oo loogu talagalay SiC

-

Kaarboon dhalo ah oo tayo sare leh oo u adkaysata daxalka...

-

Daahan Tantalum carbide: xidho u adkaysta, sare-...

-

Cabbirka Weyn ee Silicon Carbide Wafer dib loo krishay...

-

Nadiifinta Sare ee Caadiga ah ee SiC Dahaarka Garaafiga Heater H...

-

Wax qabad sare oo tantalum carbide ah oo dahaadhay dalool...