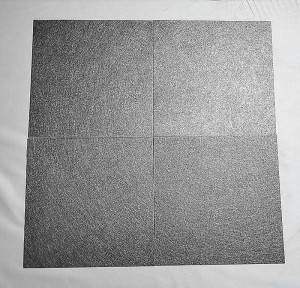

6 Inch Semi Insulating SiC Wafer oo ka socota VET Energy waa xal horumarsan oo loogu talagalay codsiyada tamarta sare iyo kuwa soo noqnoqonaya, oo bixisa kulaylka sare iyo dahaarka korantada. Waferradan yar-yar ee dahaadhka ah ayaa lagama maarmaan u ah horumarinta aaladaha sida cod-weyneyaasha RF, furayaasha korantada, iyo qaybaha kale ee korantada sare leh. Tamarta VET waxay hubisaa tayada iyo waxqabadka joogtada ah, taas oo ka dhigaysa waferradan mid ku habboon geeddi-socodyo badan oo farsamaynta semiconductor ah.

Marka lagu daro sifooyinkooda aadka u wanaagsan, waferradan SiC waxay la jaan qaadayaan agabyo kala duwan oo ay ka mid yihiin Si Wafer, SiC Substrate, SOI Wafer, SiN Substrate, iyo Epi Wafer, taasoo ka dhigaysa kuwo la jaan qaadi kara noocyada kala duwan ee hababka wax soo saarka. Waxaa intaa dheer, alaabta horumarsan sida Gallium Oxide Ga2O3 iyo AlN Wafer waxaa loo isticmaali karaa isku darka waferradan SiC, iyadoo siinaya dabacsanaan xitaa ka weyn qalabka elektiroonigga ah ee awoodda sare leh. Wafers-yada waxaa loogu talagalay is dhexgalka aan kala go 'lahayn ee nidaamyada maaraynta heerka warshadaha sida nidaamyada Cassette, hubinta fududaynta isticmaalka goobaha wax soo saarka ballaaran.

VET Energy waxa ay bixisaa faylal dhammaystiran oo ah substrates semiconductor, oo ay ku jiraan Si Wafer, SiC Substrate, SOI Wafer, SiN Substrate, Epi Wafer, Gallium Oxide Ga2O3, iyo AlN Wafer. Khadkayaga alaabada kala duwan ayaa daboolaya baahiyaha codsiyada kala duwan ee elektiroonigga ah, laga bilaabo korantada korantada ilaa RF iyo optoelectronics.

6 inch semi-insulating SiC wafer wuxuu bixiyaa faa'iidooyin dhowr ah:

Korontada burbursan ee sare: Baaxadda ballaaran ee SiC waxay awood u siineysaa koronto jabin sare, taasoo u oggolaaneysa qalab koronto oo aad u kooban oo hufan.

Hawlgalka heerkulka sare: SiC's kuleyliyaha ugu fiican ayaa awood u siinaya hawlgalka heerkulka sare, hagaajinta isku halaynta qalabka.

Iska caabin hooseeya: Aaladaha SiC waxay muujinayaan iska caabin hoose, yaraynta khasaaraha tamarta iyo hagaajinta waxtarka tamarta.

Tamarta VET waxay bixisaa wafers SiC ah oo la beddeli karo si ay u buuxiso shuruudahaaga gaarka ah, oo ay ku jiraan dhumucyada kala duwan, heerarka doping-ka, iyo dhamaystirka dusha sare. Kooxdayada khabiirku waxay bixiyaan taageero farsamo iyo adeeg iibka kadib si loo xaqiijiyo guushaada.

QAAByada WAFERING

*n-Pm=n-nooca Pm-Grade,n-Ps=n-nooca Ps-Grade,Sl=Semi-lnsulating

| Shayga | 8-inch | 6-inch | 4-inji | ||

| nP | n-Pm | n-Ps | SI | SI | |

| TTV(GBIR) | ≤6um | ≤6um | |||

| Qaanso(GF3YFCD) -Qiimaha saxda ah | ≤15μm | ≤15μm | ≤25μm | ≤15μm | |

| Warp(GF3YFER) | ≤25μm | ≤25μm | ≤40μm | ≤25μm | |

| LTV(SBIR)-10mmx10mm | <2μm | ||||

| Wafer Edge | Beveling | ||||

DHULKA DHAMMAAN

*n-Pm=n-nooca Pm-Grade,n-Ps=n-nooca Ps-Grade,Sl=Semi-lnsulating

| Shayga | 8-inch | 6-inch | 4-inji | ||

| nP | n-Pm | n-Ps | SI | SI | |

| Dhamaystir dusha sare | Polish indhaha laba-geesoodka ah,Si- Waji CMP | ||||

| Dusha sareynta | (10um x 10um) Si-FaceRa≤0.2nm | (5umx5um) Si-Face Ra≤0.2nm | |||

| Chips Edge | Midna Lama ogola (dhererka iyo ballaca≥0.5mm) | ||||

| Indents | Midna lama ogola | ||||

| xoqid (Si-Waji) | Qty.≤5, Wadar ah | Qty.≤5, Wadar ah | Qty.≤5, Wadar ah | ||

| dildilaaca | Midna lama ogola | ||||

| Ka saarida gees | 3mm | ||||

-

Soo saaraha batteriga vanadium stream ce...

-

Gaaska unugga PEM ee faafinta lakabka platinum-ku dahaaran ti...

-

Substrate-ka Silicon-Carbide ee Dahaarka leh ee S...

-

Unugyada Shidaalka Hayaroojin ee kaydka tamarta Saxnaanta Sare ee H...

-

Matoorka unugga shidaalka hydrogen-ka ee biyaha qaboojiyey oo aan...

-

Cabbirka Weyn ee Silicon Carbide Wafer dib loo krishay...