VET Energy silicon carbide (SiC) epitaxial wafer yog ib qho kev ua haujlwm siab dav bandgap semiconductor cov khoom uas muaj qhov kub thiab txias tsis kam, siab zaus thiab siab zog yam ntxwv. Nws yog qhov zoo tshaj plaws substrate rau lub cim tshiab ntawm lub zog hluav taws xob cov khoom siv hluav taws xob. VET Energy siv MOCVD epitaxial thev naus laus zis kom loj hlob zoo SiC epitaxial khaubncaws sab nraud povtseg ntawm SiC substrates, kom ntseeg tau tias kev ua tau zoo thiab sib xws ntawm wafer.

Peb Silicon Carbide (SiC) Epitaxial Wafer muaj kev sib raug zoo nrog ntau yam khoom siv semiconductor xws li Si Wafer, SiC Substrate, SOI Wafer, thiab SiN Substrate. Nrog nws cov txheej txheem epitaxial muaj zog, nws txhawb cov txheej txheem siab heev xws li Epi Wafer kev loj hlob thiab kev koom ua ke nrog cov ntaub ntawv zoo li Gallium Oxide Ga2O3 thiab AlN Wafer, kom ntseeg tau tias siv tau ntau yam thoob plaws cov thev naus laus zis sib txawv. Tsim los ua kom tau raws li kev lag luam-tus qauv Cassette tuav cov tshuab, nws ua kom muaj txiaj ntsig zoo thiab ua haujlwm tau zoo hauv cov khoom siv hluav taws xob semiconductor.

VET Energy cov khoom lag luam tsis txwv rau SiC epitaxial wafers. Peb kuj muab ntau yam khoom siv semiconductor, suav nrog Si Wafer, SiC Substrate, SOI Wafer, SiN Substrate, Epi Wafer, thiab lwm yam. Tsis tas li ntawd, peb tseem tab tom tsim cov khoom siv hluav taws xob tshiab dav dav, xws li Gallium Oxide Ga2O3 thiab AlN Wafer, kom tau raws li lub zog hluav taws xob kev lag luam yav tom ntej.

WAFFERING SPECIFICATIONS

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Qib,Sl=Semi-lnsulating

| Yam khoom | 8-Inch | 6-Inch | 4-Inch | ||

| np | n- Pm | n-Ps | SI | SI | |

| TVV (GBIR) | ≤ 6 hli | ≤ 6 hli | |||

| Hneev (GF3YFCD) - Tus Nqi Tsis Muaj | ≤15μm | ≤15μm | ≤ 25μm | ≤15μm | |

| Warp (GF3YFER) | ≤ 25μm | ≤ 25μm | ≤ 40μm | ≤ 25μm | |

| LTV (SBIR)-10mmx10mm | < 2 m os | ||||

| Wafer Ntug | Beveling | ||||

NTAU NTAU

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Qib,Sl=Semi-lnsulating

| Yam khoom | 8-Inch | 6-Inch | 4-Inch | ||

| np | n- Pm | n-Ps | SI | SI | |

| Nto tiav | Ob chav sab Optical Polish, Si- ntsej muag CMP | ||||

| SurfaceRoughness | (10um x 10um) Si-FaceRa≤0.2nm | (5umx5um) Si-Face Ra≤0.2nm | |||

| Ntug Chips | Tsis Muaj Kev Tso Cai (ntev thiab dav ≥0.5mm) | ||||

| Indents | Tsis Muaj Tso Cai | ||||

| Scratches (Si-Face) | Qty.≤ 5, Ua kom tiav | Qty.≤ 5, Ua kom tiav | Qty.≤ 5, Ua kom tiav | ||

| Kev tawg | Tsis Muaj Tso Cai | ||||

| Ntug Exclusion | 3mm ib | ||||

-

Roj Cell 1000w 24v Drone Hydrogen Roj Cell Cov Khoom Siv

-

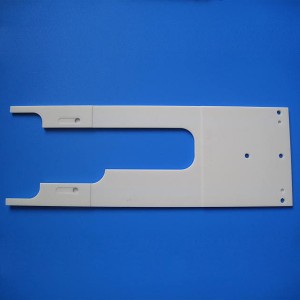

Cov khoom siv semiconductor consumables alumina cer...

-

Graphite Plug Resin Impregnated Thrust Bearings Cov...

-

High Strength Graphite / Carbon Fiber Rope rau Se...

-

1000w Pemfc Fuel Cell Stack Rau Uav Pemfc ...

-

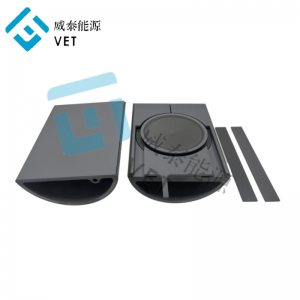

Sab saum toj thiab hauv qab Graphite Ib nrab-lub hli Part rau Si...