I-VET Energy Graphite Substrate Wafer Holder iyisiphathi esinembayo esidizayinelwe inqubo ye-PECVD (Plasma Enhanced Chemical Vapor Deposition). Lesi Sibambi Se-Graphite Substrate sekhwalithi ephezulu senziwe ngezinto ezicwebezelayo eziphakeme kakhulu, ezinokumelana nezinga lokushisa eliphakeme kakhulu, ukumelana nokugqwala, ukuzinza kwe-dimensional nezinye izici. Inganikeza inkundla yokweseka ezinzile yenqubo ye-PECVD futhi iqinisekise ukufana nokucaba kokumiswa kwefilimu.

Ithebula le-VET Energy PECVD lokusekela i-graphite wafer linezici ezilandelayo:

▪Ukuhlanzeka okuphezulu:okuqukethwe kokungcola okuphansi kakhulu, gwema ukungcoliswa kwefilimu, qinisekisa ikhwalithi yefilimu.

▪Ukuminyana okuphezulu:ukuminyana okuphezulu, amandla aphezulu emishini, angakwazi ukumelana nokushisa okuphezulu nokucindezela okuphezulu kwemvelo ye-PECVD.

▪Ukuzinza okuhle kwe-dimensional:ushintsho oluncane lwe-dimensional ekushiseni okuphezulu, okuqinisekisa ukuzinza kwenqubo.

▪I-thermal conductivity enhle kakhulu:dlulisa kahle ukushisa ukuze uvimbele ukushisisa kwe-wafer.

▪Ukumelana nokugqwala okuqinile:ingamelana nokuguguleka ngamagesi ahlukahlukene agqwalayo kanye ne-plasma.

▪Isevisi eyenziwe ngokwezifiso:amatafula okusekela ama-graphite anobukhulu obuhlukahlukene kanye nokuma kungenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende.

Izinzuzo Zomkhiqizo

▪Thuthukisa ikhwalithi yefilimu:Qinisekisa ukufakwa kwefilimu efanayo futhi uthuthukise ikhwalithi yefilimu.

▪Nweba impilo yesisetshenziswa:Ukumelana nokugqwala okuhle kakhulu, kwandisa impilo yesevisi yemishini ye-PECVD.

▪Yehlisa izindleko zokukhiqiza:Amathreyi e-graphite asezingeni eliphezulu anganciphisa izinga le-scrap futhi anciphise izindleko zokukhiqiza.

Izinto ze-graphite ezivela ku-SGL:

| Ipharamitha ejwayelekile: R6510 | |||

| Inkomba | Izinga lokuhlola | Inani | Iyunithi |

| Usayizi wokusanhlamvu omaphakathi | ISO 13320 | 10 | μm |

| Ukuminyana ngobuningi | I-DIN IEC 60413/204 | 1.83 | g/cm3 |

| I-porosity evulekile | I-DIN66133 | 10 | % |

| Usayizi wembotshana ophakathi | I-DIN66133 | 1.8 | μm |

| Ukuvumeleka | I-DIN 51935 | 0.06 | cm²/s |

| Ukuqina kwe-Rockwell HR5/100 | I-DIN IEC60413/303 | 90 | HR |

| Ukumelana nogesi okuqondile | I-DIN IEC 60413/402 | 13 | μΩm |

| Amandla e-Flexural | I-DIN IEC 60413/501 | 60 | I-MPa |

| Amandla acindezelayo | I-DIN 51910 | 130 | I-MPa |

| I-modulus yentsha | I-DIN 51915 | 11.5×10³ | I-MPa |

| Ukunwetshwa kokushisa (20-200 ℃) | I-DIN 51909 | 4.2X10-6 | K-1 |

| I-Thermal conductivity (20 ℃) | I-DIN 51908 | 105 | Wm-1K-1 |

Yakhelwe ngokukhethekile ukukhiqizwa kwamaseli elanga asebenza kahle kakhulu, asekela ukucutshungulwa kwe-wafer yosayizi omkhulu we-G12. Idizayini yenkampani yenethiwekhi ethuthukisiwe inyusa kakhulu ukusebenza, inika amandla amanani esivuno aphezulu kanye nezindleko zokukhiqiza eziphansi.

| Into | Uhlobo | Inombolo yenethiwekhi ye-wafer |

| Isikebhe se-PEVCD Grephite - Uchungechunge lwe-156 | 156-13 grephite isikebhe | 144 |

| 156-19 grephite isikebhe | 216 | |

| 156-21 grephite isikebhe | 240 | |

| 156-23 isikebhe se-graphite | 308 | |

| Isikebhe se-PEVCD Grephite - Uchungechunge lwe-125 | 125-15 grephite isikebhe | 196 |

| 125-19 grephite isikebhe | 252 | |

| 125-21 isikebhe se-grphite | 280 |

-

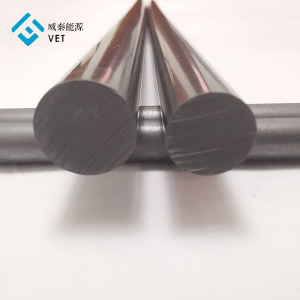

Sekela induku ye-graphite yangokwezifiso izinga lokushisa eliphezulu ...

-

Isistimu yensimu eshisayo yesithando somlilo esisodwa sekristalu

-

I-graphite crucible yokukhula kwekristalu eyodwa

-

I-Carbon Electrode Rod Graphite Rod Iyathengiswa

-

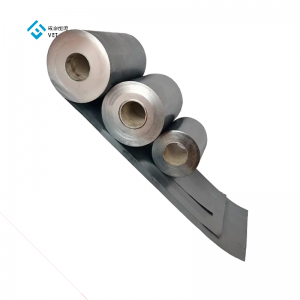

Iphepha le-graphite lamaseli kaphethiloli alikwazi ukumelana ne-h...

-

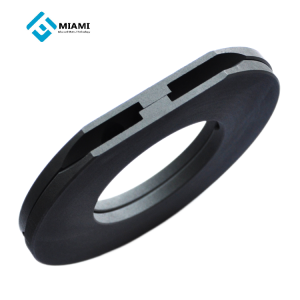

I-Half Bearing Bush I-Resin Yemikhono Yekhabhoni Yangokwezifiso...