Sinabasebenzi abaninzi ababalaseleyo abathengi abagqwesileyo ekukhuthazeni, i-QC, kunye nokusebenza ngeentlobo zobunzima obuyingxaki ngaphakathi kwendlela yokuvelisa i-Super Purchasing ye-China ye-SSic+C ye-Oring ejikelezayo ye-Cramic Seal Ring ye-Mechanical Seal, iimveliso zethu kunye nezisombululo ngabathengi abatsha nabaphelelwe lixesha ukuqondwa kunye nokuthenjwa. Samkela abathengi abatsha nabangaphambili ukuba baqhagamshelane nathi malunga nobudlelwane beshishini obunokubakho, uphuculo oluqhelekileyo. Masihambe ngesantya ngaphakathi ebumnyameni!

Sinabasebenzi abaninzi ababalaseleyo abathengi abagqwesileyo ekukhuthazeni, i-QC, kunye nokusebenza ngeentlobo zobunzima obuyingxaki ngaphakathi kwendlela yokuvelisaChina I-Sic+C itywina iRingi, I-Sic+C yokutywinwa, Kuya kufuneka uzive ungenandleko ukusithumela iinkcukacha zakho kwaye siya kukuphendula ngokukhawuleza. Sineqela lobunjineli abanezakhono zokusebenzela zonke iimfuno ezinzulu. Iisampulu zasimahla zinokuthunyelwa kwimeko yakho ukuze wazi iinyani ezingaphezulu. Ukuze ukwazi ukuhlangabezana neminqweno yakho, qiniseka ukuba ngokwenene uziva ukhululekile ukuba uqhagamshelane nathi. Ungasithumelela ii-imeyile kwaye usitsalele umnxeba ngokuthe ngqo. Ukongeza, siyakwamkela ukutyelelwa komzi-mveliso wethu ovela kwihlabathi liphela ngenjongo yokuqonda ngcono umbutho wethu. kunye neentengiso. Kurhwebo lwethu kunye nabarhwebi bamazwe amaninzi, sihlala sibambelela kumgaqo wokulingana kunye nokuxhamla. Lithemba lethu lokuthengisa, ngemizamo edibeneyo, ukurhweba kunye nobuhlobo ukuze sizuze sonke. Sijonge phambili ekufumaneni imibuzo yakho.

ISintered Silicon Carbide Ceramic Bushing

I-silicon carbide engenaxinzelelo (SSIC)iveliswa kusetyenziswa umgubo we-SiC ocolekileyo kakhulu oqulethe izongezo ze-sintering. Icutshungulwa kusetyenziswa iindlela zokubumba eziqhelekileyo kwezinye iikeramics kunye ne-sintered kwi-2,000 ukuya kwi-2,200 ° C kwi-atmosphere ye-inert yegesi.Kwakunye neenguqulelo ezicoliweyo, ezinobungakanani bengqolowa <5 um, iinguqulelo ezicoliweyo ezinobukhulu obuziinkozo ukuya kwi-1.5 mm ziyafumaneka.

I-SSIC yohlulwa ngamandla aphezulu ahlala phantse ngokuthe rhoqo ukuya kumaqondo obushushu aphezulu kakhulu (malunga ne-1,600° C), egcina loo mandla ixesha elide!

Iinzuzo zemveliso:

Ukumelana ne-oxidation yobushushu obuphezulu

Uxhathiso olugqwesileyo lweCorrosion

Ukuxhathisa okulungileyo kweAbrasion

I-coefficient ephezulu yokushisa ukushisa

Ukuzithambisa, ukuxinana okuphantsi

Ukuqina okuphezulu

Uyilo olulungiselelweyo.

Iimpawu zobugcisa:

| Izinto | Iyunithi | Idatha |

| Ukuqina | HS | ≥110 |

| Inqanaba le-Porosity | % | <0.3 |

| Ukuxinana | g/cm3 | 3.10-3.15 |

| Ukucinezela | MPa | >2200 |

| Ukomelela Kweqhekeza | MPa | >350 |

| I-Coefficient yokwandiswa | 10/°C | 4.0 |

| Umxholo weSic | % | ≥99 |

| I-Thermal conductivity | W/mk | >120 |

| Imodyuli ye-elastic | GPA | ≥400 |

| Ubushushu | °C | 1380 |

-

Ibhloko yekhabhoni yegraphite yexabiso eliphezulu esetyenziselwa ...

-

I-Antimony efakwe itywina yegraphite iringi yekhabhoni

-

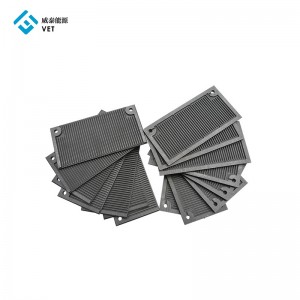

I-Fuel Cell Grade Graphite Plate, iCarbon bipolar ...

-

Ibhlokhi yeCarbon Graphite, isostatic icinezela igrafu...

-

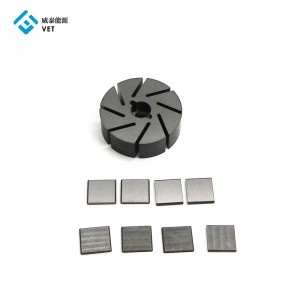

I-Carbon graphite rotor iyathengiswa

-

Ikhabhoni yegraphite vane yeempompo zebusch vacuum

-

Iimpompo zempompo zekharbhoni zokwenziwa kwevacuum & vac...

-

Amakhonkco ekhabhoni kwiitywina zoomatshini, iringi yegraphite...

-

Umsesane wekhabhoni wokutywina, amakhonkco ePiston yeGraphite yeRo...

-

Umzi-mveliso waseTshayina we-Sintered Silicon Carbid...

-

Udongwe lwegraphite crucible otational Ukubumba uhlobo

-

Ipleyiti ye-electrode ehlanganisiweyo ye-vanadium redox fl...

-

Umzobo weGraphite ococekileyo ococekileyo oSetyenzisiweyo ophinde usetyenziswe ngexabiso eliphantsi...

-

Izinto zokufudumeza zegraphite yesiko, iinxalenye zekhabhoni f...

-

Isifudumezi seGraphite esenzelwe wena kwiSemiconductor kwiSi...

-

Ukunyibilika kweMetal okulungiselelwe i-SIC Ingot Mould, iSilico...