Sineqela lethu lokuthengisa, iqela loyilo, iqela lobugcisa, iqela le-QC kunye neqela lephakheji. Sineenkqubo ezingqongqo zokulawula umgangatho wenkqubo nganye. Kwakhona, bonke abasebenzi bethu banamava kwintsimi yoshicilelo ngexabiso elicatshulweyo leChina eliPhezulu loBubushushu obuMela ukuHlaza iSilicon Carbide Abrasive Powder Black Silicon Carbide Powder yokupholisha, inzuzo yabaThengi kunye nokwaneliseka ngokuqhelekileyo yeyona njongo yethu inkulu. Khumbula ukunxibelelana nathi. Sinike ithuba, sikubonelele ngokumangalisayo.

Sineqela lethu lokuthengisa, iqela loyilo, iqela lobugcisa, iqela le-QC kunye neqela lephakheji. Sineenkqubo ezingqongqo zokulawula umgangatho wenkqubo nganye. Kwakhona, bonke abasebenzi bethu banamava kwintsimi yokushicilelaChina Silicon Carbide, Sic, Yintoni ixabiso elihle? Sinika abathengi ngexabiso lasefektri. Kwisiseko somgangatho olungileyo, ukusebenza kakuhle kufuneka kuthathelwe ingqalelo kwaye kugcinwe iingeniso ezifanelekileyo eziphantsi nezisempilweni. Yintoni ukuhanjiswa okukhawulezayo? Senza ukuhanjiswa ngokweemfuno zabathengi. Nangona ixesha lokuhambisa lixhomekeke kubungakanani bomyalelo kunye nobunzima balo, sisazama ukubonelela ngeemveliso kunye nezisombululo ngexesha. Ngethemba elinyanisekileyo sinokuba nobudlelwane beshishini bexesha elide.

Ingcaciso yeMveliso

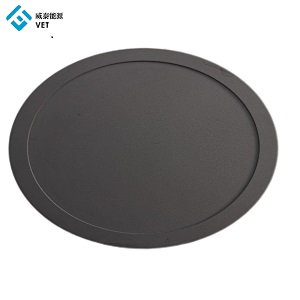

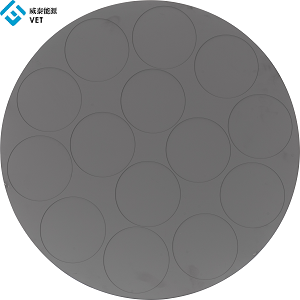

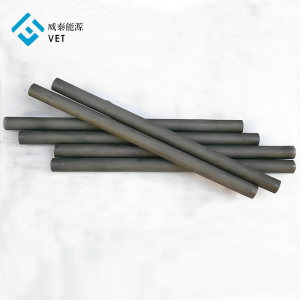

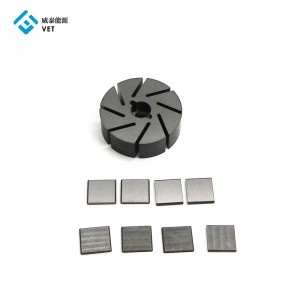

Inkampani yethu ibonelela ngeenkonzo zenkqubo yokugquma kwe-SiC ngendlela ye-CVD kumphezulu wegraphite, iiseramikhi kunye nezinye izinto, ukwenzela ukuba iigesi ezikhethekileyo ezinekhabhoni kunye nesilicon zisabela kubushushu obuphezulu ukuze zifumane ubunyulu obuphezulu beamolekyuli ze-SiC, iimolekyuli ezifakwe kumphezulu wezinto ezigqunyiweyo, zenza umaleko wokhuselo we-SIC.

Iimpawu eziphambili:

1. Ukumelana nobushushu obuphezulu be-oxidation: ukumelana ne-oxidation kusekuhle kakhulu xa ubushushu buphezulu njenge-1600 C.

2. Ukucoceka okuphezulu : yenziwe yi-chemical vapor deposition phantsi kwemeko yokushisa kwe-chlorination ephezulu.

3. Ukumelana nokhukuliseko: ubunzima obuphezulu, indawo edibeneyo, iincinci ezincinci.

4. Ukumelana nokubola: i-asidi, i-alkali, ityuwa kunye nee-reagents eziphilayo.

IiNgcaciso eziphambili ze-CVD-SIC Coating

| Iipropati zeSiC-CVD | ||

| Ulwakhiwo lweCrystal | iFCC β isigaba | |

| Ukuxinana | g/cm ³ | 3.21 |

| Ukuqina | Vickers ubulukhuni | 2500 |

| Ubungakanani benkozo | μm | 2~10 |

| Ucoceko lweMichiza | % | 99.99995 |

| Ubushushu Umthamo | J·kg-1 ·K-1 | 640 |

| Iqondo lobushushu elisezantsi | ℃ | 2700 |

| Amandla eFelexural | MPa (RT 4-point) | 415 |

| Imodulus eselula | I-Gpa (4pt bend, 1300℃) | 430 |

| Ukwandiswa kweThermal (CTE) | 10-6K-1 | 4.5 |

| I-Thermal conductivity | (W/mK) | 300 |

-

Intengiso eshushu yeGrafite eYandisiweyo ecocekileyo eYandisiweyo...

-

Isaphulelo kwihoseyile yeXesha elide Ubonelelo lweCarbon E...

-

Ixabiso eliphantsi le-China High Quality Graphite Rotor...

-

Umzi-mveliso ubonelela ngokuthe ngqo eTshayina ePhakamileyo ePure Carbon ...

-

Ixabiso lesaphulelo Ngokufanelekileyo kwaye liZinzile 60kw W...

-

Umgangatho ogqwesileyo wokuphela kobuso boMechanical Seal Grap...