Hot field system of polycrystalline ingot furnace

The hot field system of polycrystalline ingot casting furnace is the key equipment of polycrystalline ingot casting in photovoltaic industry. The company's products mainly include roof, heating body, cover plate, protection plate and other parts

|

serial number |

product name |

Sample drawing of product parts |

product superiority |

main performance index |

|

1 |

Top plate |

Quasi-three-dimensional structure, high carbon fiber content, using hot pressing and resin impregnation densification process, short production cycle, the mechanical properties of the same density than isostatic pressure graphite materials. |

VET: Density 1.3g /cm3, tensile strength :180Mpa, bending strength :150Mpa Competitors: 1.35g/cm3, tensile strength ≥180MPa, bending strength ≥140MPa

|

|

|

2 |

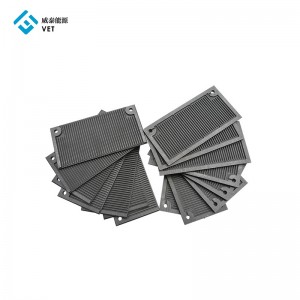

Cover plate |

Quasi-three-dimensional structure, high carbon fiber content, using hot pressing and resin impregnation densification process, short production cycle, with good thermal insulation performance, long service life and other advantages. |

VET: Density 1.4g /cm3, tensile strength :208Mpa, bending strength :195Mpa Competitors: 1.45g /cm3, tensile strength ≥200MPa, bending strength ≥160MPa

|

|

|

3 |

Guard plate |

Quasi-three-dimensional structure, high carbon fiber content, using hot pressing and resin impregnation densification process, short production cycle, the mechanical properties of the same density than pure vapor deposition products. |

VET: Density 1.4g /cm3, tensile strength :208Mpa, bending strength :195Mpa Competitors: 1.45g /cm3, tensile strength ≥200MPa, bending strength ≥160MPa

|

|

|

4 |

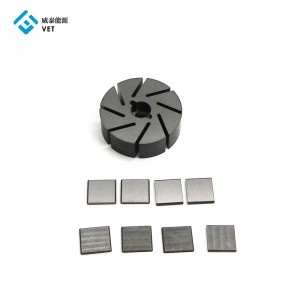

Heating body |

Through the microstructure design, the product resistivity is improved, quasi-three-dimensional structure, high carbon fiber content, using hot pressing and resin impregnation densification process, short production cycle, the same density, its mechanical properties are better than pure vapor deposition products, long service life. |

VET: Density 1.5g/cm3, Bending strength: 220MPa Resistivity: 18-22x10-5Ω*m Competitors: 1.5g /cm3, Bending strength: 210MPa Resistivity: 18-22x10-5Ω*m

|

|

|

5 |

fastener |

Through the microstructure design, the interlayer density of the product is improved, the transition layer is uniform between the layers, and the interlayer bonding force is good. The differential pressure vapor deposition densification process is adopted, and the densification is uniform, and the machined product rate is high. |

VET: Density 1.45g/cm3, bending strength: 160Mpa; Competitors: Density 1.4g /cm3, bending strength: 130MPa

|

|

|

6 |

Insulation strip |

Adopt a variety of processes for surface treatment, reduce dust in the furnace, convenient disassembly furnace, long service life of products. |

VET: Density ≤0.16 g/cm3 Competitor: Density ≤ 0.18g /cm3

|

-

Quality Inspection for China Antioxidation Grap...

-

Supply ODM China Graphite Felt Carbon Graphite ...

-

Price Sheet for China Direct Supply High Conduc...

-

OEM/ODM Manufacturer High Efficiency Stainless ...

-

SiC coating graphite MOCVD Wafer carriers, Gra...

-

OEM China Supply Flexible Graphite Molded Packi...