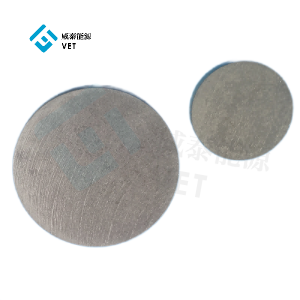

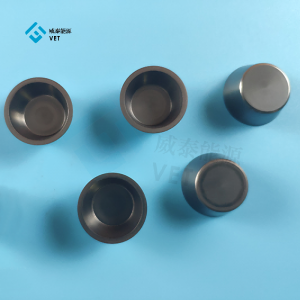

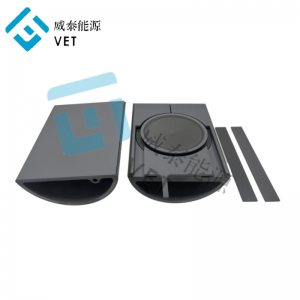

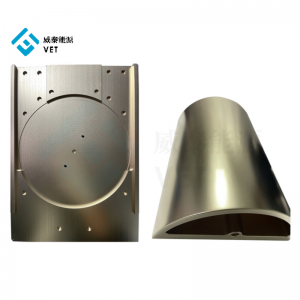

Tantalum Carbide Coating Guide Rings, this product combines Vet-China's cutting-edge CVD coating process to ensure that it provides excellent performance under various harsh conditions. Our Tantalum Carbide material has extremely high hardness and wear resistance, making it an ideal choice for high-load applications.

In high temperature and highly corrosive environments, the excellent wear resistance of Tantalum Carbide Coating Guide Rings can significantly extend the service life of equipment and reduce maintenance frequency. These rings perform well in the semiconductor manufacturing and chemical industries, ensuring that equipment continues to operate stably under high performance.

Choose Vet-China's Tantalum Carbide Coating Guide Rings, you will experience unparalleled product quality and performance. We are committed to providing customers with the best solutions to help your industrial applications improve efficiency and reliability. Whether in extreme working conditions or ordinary environments, these high-hardness guide rings will provide you with strong support and protection.

Vet-China has always focused on technological innovation and customer satisfaction. The launch of Tantalum Carbide Coating Guide Rings marks another breakthrough in our materials science and engineering technology. We look forward to working with you to jointly advance the industry.

TaC coating is a kind of tantalum carbide (TaC) coating prepared by physical vapor deposition technology, it has the following characteristics:

1. High hardness: TaC coating hardness is high, usually can reach 2500-3000HV, is an excellent hard coating.

2. Wear resistance: TaC coating is very wear-resistant, which can effectively reduce the wear and damage of mechanical parts during use.

3. Good high temperature resistance: TaC coating can also maintain its excellent performance under high temperature environment.

4. Good chemical stability: TaC coating has good chemical stability and can resist many chemical reactions, such as acids and bases.

|

碳化钽涂层物理特性物理特性 Physical properties of TaC coating |

|

|

密度 / Density |

14.3 (g/cm³) |

|

比辐射率 / Specific emissivity |

0.3 |

|

热膨胀系数 / Thermal expansion coefficient |

6.3 10-6/K |

|

努氏硬度 / Hardness (HK) |

2000 HK |

|

电阻 / Resistance |

1×10-5 Ohm*cm |

|

热稳定性 / Thermal stability |

<2500℃ |

|

石墨尺寸变化 / Graphite size changes |

-10~-20um |

|

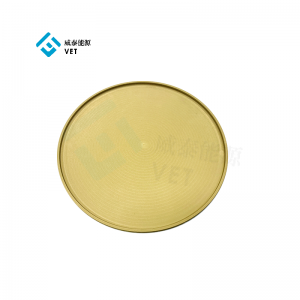

涂层厚度 / Coating thickness |

≥20um typical value (35um±10um) |

Ningbo VET Energy Technology Co., Ltd is a high-tech enterprise focusing on the production and sales of high-end advanced materials, the materials and technology covering graphite, silicon carbide, ceramics, surface treatment and so on. The products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc..

Our technical team comes from top domestic research institutions, can provide more professional material solutions for you.

Warmly welcome you to visit our factory, let's have further discussion!