Re na le bareki ba bangata ba hloahloa ba hloahloa ho phahamiseng, QC, le ho sebetsa ka mefuta ea mathata a thata ka har'a mokhoa oa ho reka bakeng sa Super Purchasing bakeng sa China SSic+C Oring Rotating Creramic Seal Ring bakeng sa Mechanical Seal, Lihlahisoa tsa rona le tharollo ke bareki ba bacha le ba siiloeng ke nako ka mokhoa o ts'oanang. Re amohela bareki ba bacha le ba nakong e fetileng ho ikopanya le rona bakeng sa likamano tse ka bang teng tsa khoebo, ntlafatso e tloaelehileng. A re phakiseng ka hare ho lefifi!

Re na le bareki ba bangata ba hloahloa ba hloahloa ho phahamiseng, QC, le ho sebetsa ka mefuta ea mathata a thata ka har'a mokhoa oa ho hlahisaChina SSic + C Seal Ring, Ho Tiisa SSic+C, U lokela ho ikutloa u lokolohile ho re romella lintlha tsa hau 'me re tla u araba kapele. Re na le sehlopha sa boenjiniere se hloahloa ho sebeletsa litlhoko tsohle tse tebileng. Mehlala ea mahala e ka romelloa molemong oa hau ho tseba lintlha tse ngata haholo. E le hore u tsebe ho finyella litakatso tsa hau, etsa bonnete ba hore u ikutloa u lokolohile ho ikopanya le rona. O ka re romella mangolo-tsoibila mme oa re letsetsa hang-hang. Ho feta moo, re thabela ho etela fektheri ea rona ho tsoa lefats'eng lohle bakeng sa ho tsebahatsa mokhatlo oa rona hamolemo. le thepa. Khoebong ea rona le bahoebi ba linaha tse 'maloa, hangata re khomarela molao-motheo oa ho lekana le ho thusana. Ke tšepo ea rona ho rekisa, ka boiteko bo kopanetsoeng, khoebo le setsoalle molemong oa rona. Re labalabela ho fumana lipotso tsa hau.

Sintered Silicon Carbide Ceramic Bushing

Sintered silicon carbide (SSIC)e hlahisoa ho sebelisoa phofo e ntle haholo ea SiC e nang le li-additives tsa sintering. E sebetsoa ka ho sebelisa mekhoa ea ho etsa e tloaelehileng bakeng sa li-ceramics tse ling 'me e siiloe ka 2,000 ho 2,200 ° C moeeng oa khase ea inert. Hape hammoho le liphetolelo tse ntle, tse nang le boholo ba lijo-thollo <5 um, liphetolelo tse mahoashe tse nang le boholo ba lijo-thollo ho fihlela ho 1.5 mm li fumaneha.

SSIC e khetholloa ka matla a phahameng a lulang a batla a sa fetohe ho fihlela mocheso o phahameng haholo (hoo e ka bang 1,600 ° C), a boloka matla ao ka nako e telele!

Melemo ea sehlahisoa:

Ho hanyetsa mocheso o phahameng oa oxidation

E babatsehang Corrosion resistance

Khahlano e ntle ea Abrasion

High coefficient ea mocheso conductivity

Ho itšehla thajana, boima bo tlase

Boima bo phahameng

Moralo o hlophisitsoeng.

Thepa ea tekheniki:

| Lintho | Yuniti | Lintlha |

| Ho thatafala | HS | ≥110 |

| Porosity Rate | % | <0.3 |

| Botenya | g/cm3 | 3.10-3.15 |

| E hatellang | MPa | >2200 |

| Matla a Fractural | MPa | >350 |

| Coefficient ea katoloso | 10/°C | 4.0 |

| Litaba tsa Sic | % | ≥99 |

| Thermal conductivity | W/mk | >120 |

| Elastic modulus | GPA | ≥400 |

| Mocheso | °C | 1380 |

-

Litheko tse ngata ka ho fetisisa tsa carbon graphite block tse sebelisetsoang ...

-

Antimony e kentsoeng tiiso ea graphite carbon ring

-

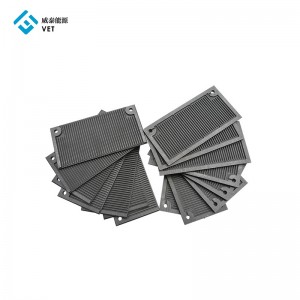

Fuel Cell Grade Graphite Plate, Carbon bipolar ...

-

Carbon Graphite Block, graph e hatellang ea isostatic...

-

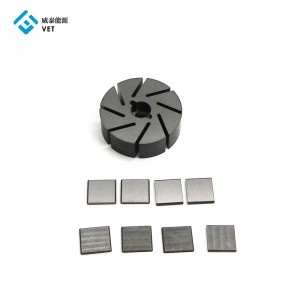

Carbon graphite rotor ea rekisoa

-

Carbon graphite vane bakeng sa lipompo tsa busch vacuum

-

Liphanele tsa pompo ea carbon bakeng sa ho etsa vacuum & vac...

-

Mehele ea khabone ka litiiso tsa mochini, selikalikoe sa graphite ...

-

Carbon seal ring , Graphite Piston Rings bakeng sa Ro...

-

Feme ea China bakeng sa China Sintered Silicon Carbid...

-

Clay graphite crucible otational Molding mofuta

-

Letlapa le kopaneng la electrode bakeng sa vanadium redox fl...

-

Customable cheap reusable High Pure Graphite Graphi...

-

Lintho tse futhumatsang tsa graphite, likarolo tsa carbon f ...

-

Sefuthumatsi sa Graphite se ikhethileng bakeng sa Semiconductor Si...

-

Customized Melting SIC Ingot Mould,Silico...