SiC e koahetsoeng kaSubstrate ea graphite bakeng sa Semiconductor, ho roala ha silicon carbide,Motlatsi oa MOCVD,

Substrate ea graphite, Substrate ea graphite bakeng sa Semiconductor, Motlatsi oa MOCVD, Silicon Carbide Coating,

Melemo e khethehileng ea li-susceptors tsa graphite tse koahetsoeng ka SiC li kenyelletsa bohloeki bo phahameng haholo, ho roala homogenous le bophelo bo botle ba ts'ebeletso. Li boetse li na le khanyetso e phahameng ea lik'hemik'hale le thepa ea botsitso ba mocheso.

Ho roala ha SiC eaSubstrate ea graphitebakeng sa lits'ebetso tsa Semiconductor e hlahisa karolo e nang le bohloeki bo phahameng le ho hanyetsa sepakapaka sa oxidizing.

CVD SiC kapa CVI SiC e sebelisoa ho Graphite ea likarolo tse bonolo kapa tse rarahaneng tsa moralo. Ho roala ho ka sebelisoa ka botenya bo sa tšoaneng le likarolong tse kholo haholo.

Likaroloana:

· Excellent Thermal Shock Resistance

· Ho Hanyetsa ho Tšoaroa ha 'Mele ho babatsehang

· Excellent Chemical Resistance

· Bohloeki bo Phahameng ka ho Fetisisa

· Ho fumaneha ka Sebopeho se Ratang

· E ka sebelisoa tlas'a Oxidizing Atmosphere

Maemo a Tloaelehileng a Base Graphite Material:

| Tekano e Hlahang: | 1.85 g/cm3 |

| Ho hanyetsa Motlakase: | 11 μΩm |

| Flexural Strenth: | 49 MPa (500kgf/cm2) |

| Bothata ba Lebōpo: | 58 |

| Molora: | <5ppm |

| Thermal Conductivity: | 116 W/mK (100 kcal/mhr-℃) |

Carbon e fana ka li-susceptors le likarolo tsa graphite bakeng sa lisebelisoa tsohle tsa morao-rao tsa epitaxy. Potefolio ea rona e kenyelletsa li-barrel susceptors bakeng sa li-unit tse kentsoeng le tsa LPE, li-susceptors tsa pancake bakeng sa LPE, CSD, le li-unit tsa Gemini, le li-susceptors tse nang le sephaephe se le seng bakeng sa li-unit tse kentsoeng le tsa ASM.

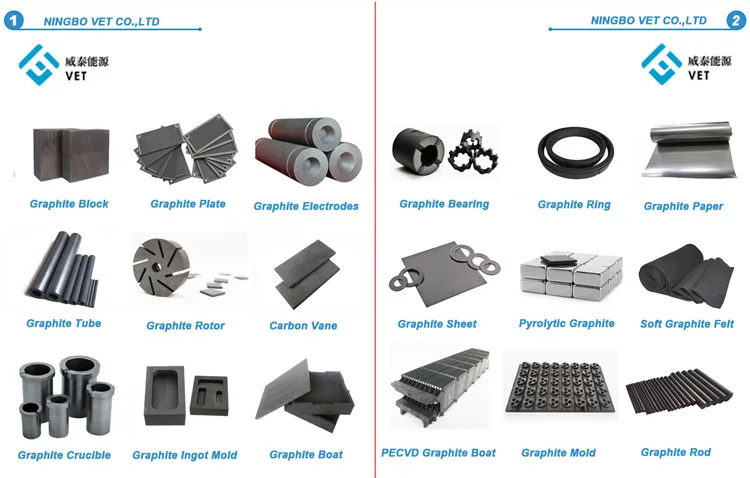

Lihlahisoa tse ling

-

Sefuthumatsi sa graphite Silicon carbide (SiC) SiC coati...

-

Sefuthumatsi sa Graphite se ikhethileng bakeng sa Semiconductor Si...

-

Customized Melting SIC Ingot Mould,Silico...

-

customized Silicon SIC hlobo silicon SSIC RBSIC...

-

CVD SiC Coated Carbon-carbon Composite CFC Seketsoana...

-

Plate e Kopantsoeng ea Carbon-Carbon E Nang le SiC Coating

-

CVD sic coating carbon-carbon composite hlobo

-

CVD sic barbotage cc composite molamu, silicon carbi ...

-

khauta le silevera casting hlobo Silicon Mould, Si...