Re boetse re tsepamisitse maikutlo ho ntlafatseng tsamaiso ea lintho le lenaneo la QC e le hore re ka boloka monyetla o motle ka har'a khoebo e hlolisanoang haholo bakeng sa Lihlahisoa tsa Batho China Silicon Carbon Crucible for Ferrous and Non-Ferrous Alloys, Ho fumana tsoelo-pele e tsitsitseng, e nang le phaello, le tsoelo-pele e sa khaotseng ka ho fumana mohiruoa oa rona molemong oa ho ba le tlholisano e tsoelang pele le ho eketsa litheko tsa rona.

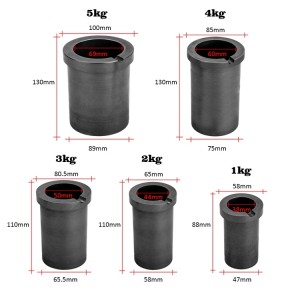

Re boetse re tsepamisitse maikutlo ho ntlafatseng tsamaiso ea lintho le lenaneo la QC e le hore re ka boloka monyetla o motle ka har'a khoebo e hlolisang ka matla bakeng saChina Silika Graphite Crucible, Graphite Foundry Crucible, Khamphani ea rona ke morekisi oa machaba oa thepa ea mofuta ona. Re fana ka khetho e makatsang ea thepa ea boleng bo holimo. Sepheo sa rona ke ho u thabisa ka pokello ea rona e ikhethang ea lintho tse hlokolosi ha re ntse re fana ka boleng le tšebeletso e babatsehang. Sepheo sa rona se bonolo: Ho fana ka lintho tse molemo ka ho fetisisa le tšebeletso ho bareki ba rona ka theko e tlaase ka ho fetisisa.

Lisebelisoa tsa carbon / carbon(eo ka mor'a moo e bitsoang "C / C kapa CFC") ke mofuta oa lintho tse entsoeng ka motsoako o thehiloeng holim'a carbon le ho matlafatsoa ke carbon fiber le lihlahisoa tsa eona (carbon fiber preform). E na le inertia ea carbon le matla a phahameng a carbon fiber. E na le thepa e ntle ea mochini, ho hanyetsa mocheso, ho hanyetsa kutu, ho fokotsa likhohlano le litšobotsi tsa motlakase le tsa motlakase.

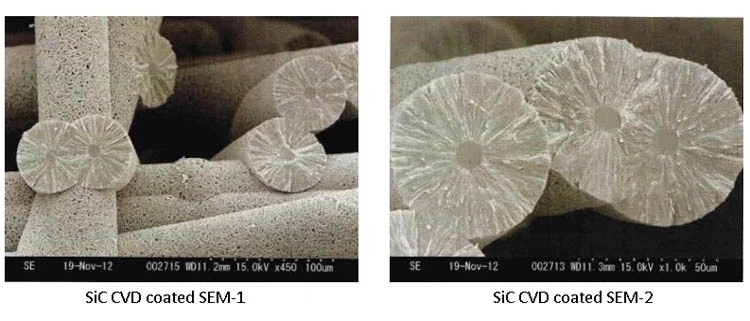

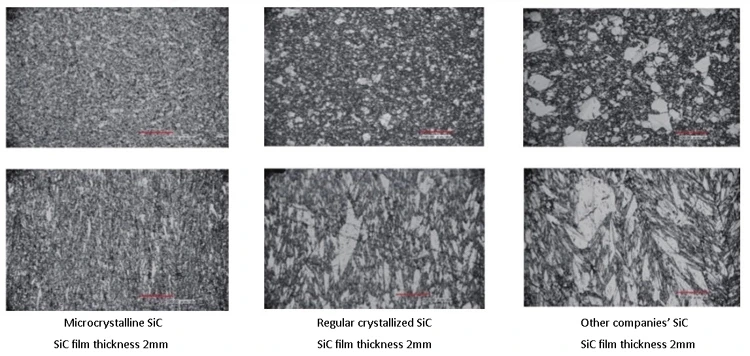

CVD-SiCbarbotage na le litšobotsi tsa sebopeho junifomo, thepa diseke ee, phahameng mocheso hanyetsa, khanyetso oxidation, bohloeki phahameng, acid & alkali ho hanyetsa le reagent manyolo, le thepa e tsitsitseng 'meleng le lik'hemik'hale.

Ha ho bapisoa le lisebelisoa tse phahameng tsa graphite, graphite e qala ho oxidize ho 400C, e tla baka tahlehelo ea phofo ka lebaka la oxidation, e leng se bakang tšilafalo ea tikoloho ho lisebelisoa tsa peripheral le likamore tsa vacuum, le ho eketsa litšila tsa tikoloho e hloekileng.

Leha ho le joalo, ho roala ha SiC ho ka boloka botsitso ba 'mele le lik'hemik'hale ka likhato tse 1600, E sebelisoa haholo indastering ea sejoale-joale, haholo indastering ea semiconductor.

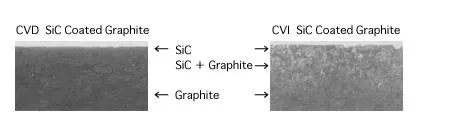

Khamphani ea rona e fana ka lits'ebeletso tsa ts'ebetso ea ho roala ka SiC ka mokhoa oa CVD holim'a graphite, li-ceramics le lisebelisoa tse ling, e le hore likhase tse khethehileng tse nang le k'habone le silicon li sebetsane le mocheso o phahameng ho fumana limolek'hule tsa SiC tse hloekileng, limolek'hule tse behiloeng holim'a lisebelisoa tse koahetsoeng, li etsa lera la tšireletso la SIC. SIC e entsoeng e tlamahane ka thata ho setsi sa graphite, e fana ka lisebelisoa tse khethehileng tsa graphite, kahoo e etsa hore bokaholimo ba graphite bo kopane, bo se ke ba e-ba le Porosity, ho hanyetsa mocheso o phahameng, ho hanyetsa kutu le ho hanyetsa oxidation.

Lintlha tse ka sehloohong:

1. Ho hanyetsa mocheso o phahameng oa oxidation:

khanyetso ea oxidation e ntse e le ntle haholo ha mocheso o le holimo ho 1600 C.

2. Bohloeki bo phahameng: bo entsoeng ka ho kenngoa ha mouoane oa lik'hemik'hale tlas'a boemo bo phahameng ba mocheso oa chlorination.

3. Ho hanyetsa khoholeho ea mobu: boima bo phahameng, bokaholimo bo kopanetsoeng, likaroloana tse ntle.

4. Ho hanyetsa kutu: acid, alkali, letsoai le li-reagents tse phelang.

Lintlha tse ka sehloohong tsa CVD-SIC Coatings:

| SiC-CVD | ||

| Botenya | (g/cc)

| 3.21 |

| Matla a flexural | (Mpa)

| 470 |

| Katoloso ea mocheso | (10-6/K) | 4

|

| Thermal conductivity | (W/mK) | 300

|