Bophelo bo boleleleSIC e koahetsoeng ka Graphite Heaterbakeng sa MOCVD K465i, Graphite Heater bakeng sa epitaxy,

heater ea graphite, Graphite Heater bakeng sa MOCVD, heater, SIC e koahetsoeng ka Graphite Heater,

MOCVD Substrate Heater, Lisebelisoa tsa ho futhumatsa bakeng sa MOCVD

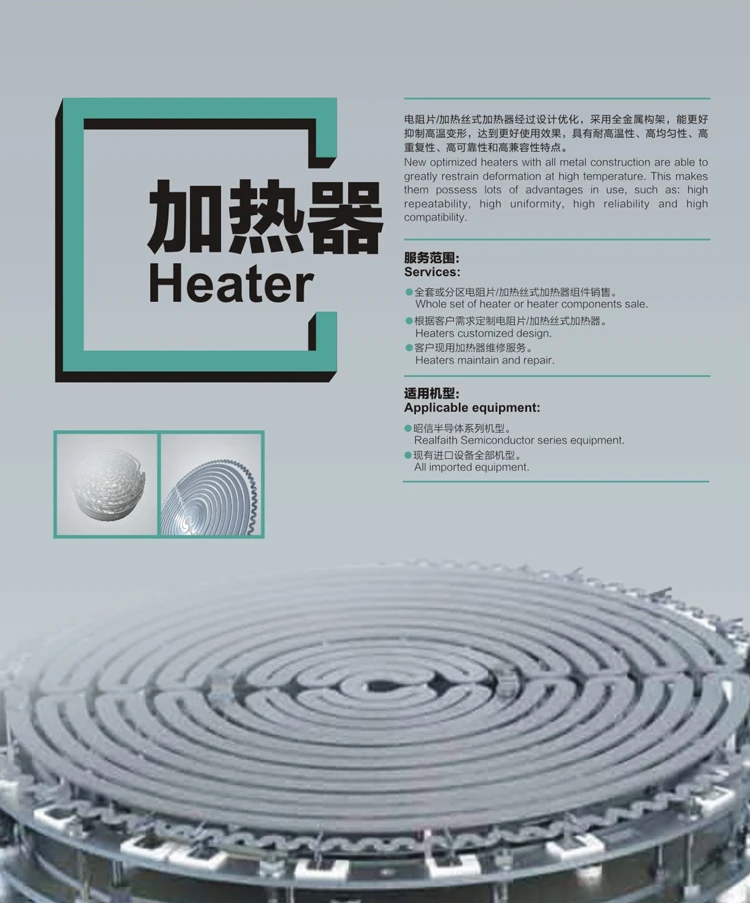

Graphiteheater:

Theheater ea graphitelikarolo li sebelisoa seboping se phahameng sa mocheso se nang le mocheso o fihlileng ho likhato tse 2200 sebakeng sa vacuum le likhato tse 3000 sebakeng sa khase e nang le deoxidized le e kentsoeng.

Lintho tse ka sehloohong tsa heater ea graphite:

1. ho tšoana ha mohaho oa ho futhumatsa.

2. conductivity e ntle ea motlakase le mojaro o phahameng oa motlakase.

3. ho hanyetsa kutu.

4. inoxidizability.

5. bohloeki bo phahameng ba lik'hemik'hale.

6. matla a phahameng a mechine.

Molemo ke matla a matla, boleng bo phahameng le tlhokomelo e tlaase.

Re ka hlahisa anti-oxidation le nako e telele ea bophelo ba graphite crucible, hlobo ea graphite le likarolo tsohle tsa heater ea graphite.

Lintlha tse ka sehloohong tsa heater ea graphite:

| Tlhaloso ea Setsebi | VET-M3 |

| Boima ba Bongata (g/cm3) | ≥1.85 |

| Litaba tsa Molora (PPM) | ≤500 |

| Bothata ba Lebopo | ≥45 |

| Khanyetso e Khethehileng (μ.Ω.m) | ≤12 |

| Flexural Strength (Mpa) | ≥40 |

| Compressive Strength (Mpa) | ≥70 |

| Max. Boholo ba Mabele (μm) | ≤43 |

| Coefficient of Thermal Katoloso Mm/°C | ≤4.4 * 10-6 |

Mofuthu oa graphite bakeng sa sebōpi sa motlakase o na le thepa ea ho hanyetsa mocheso, ho hanyetsa oxidation, conductivity e ntle ea motlakase le matla a molemo a mochine. Re ka sebelisa mefuta e fapaneng ea heater ea graphite ho latela meralo ea bareki.

-

Silicone ring carbon seal ring pompo ea mochini ...

-

1KW Air-Cooling Hydrogen Fuel Cell Stack e nang le M...

-

Carbon graphite rotor e qala sehlahisoa se secha Chaena

-

2kW pem fuel cell hydrogen jenereithara, matla a macha ...

-

3kW hydrogen fuel cell , mafura cell stack

-

6KW Hydrogen Fuel Cell Stack, jenereithara ea haedrojene...

-

Lesela le kentsoeng la Carbon Fiber, le entsoeng ka khabone ...

-

Aero Graphite Mold Bakeng sa Photovoltaic

-

Anti-Oxidant Graphite Rotor le Shaft bakeng sa Alumi...

-

Litheko tse ngata ka ho fetisisa tsa carbon graphite block tse sebelisetsoang ...

-

Morekisi ea nang le Carbon Graphite Mold ea boleng bo holimo

-

Bipolar plate hydrogen fuel cell jenereithara 40 k...

-

Theko e tlase China Manufacture of Carbon Graphi...

-

pompo ea metsi ea potoloho ea koloi, Potoloho ea Pholiso ...

-

Carbon block price , tšepe e khotsofetse bakeng sa mocheso t ...