Ho latela khopolo ea "boleng, lits'ebeletso, ts'ebetso le kholo", re amohetse litšepiso le thoriso ho tsoa ho moreki oa lapeng le lefats'e ka bophara bakeng sa Setifikeiti sa IOS China 99.5%Sepheo sa Sic CeramicSilicon Carbide Sputtering Target for Coating, Sepheo sa rona sa mantlha ke ho fa bareki ba rona lefats'eng ka bophara boleng bo botle, theko ea tlholisano, phano e khotsofatsang le lits'ebeletso tse ntle haholo.

Ho latela khopolo ea "boleng, lits'ebeletso, ts'ebetso le kholo", re amohetse litšepiso le thoriso ho tsoa ho shopper ea lapeng le lefats'e ka bophara bakeng saChina Silicon Carbide Sputtering Target, Sepheo sa Sic Ceramic, Hona joale re na le tsamaiso e thata le e feletseng ea taolo ea boleng, e tiisang hore sehlahisoa se seng le se seng se ka finyella litlhoko tsa boleng ba bareki. Ntle le moo, lintho tsohle tsa rona li hlahlobiloe ka thata pele li romelloa.

Lisebelisoa tsa carbon / carbon(eo ka mor'a moo e bitsoang "C / C kapa CFC") ke mofuta oa lintho tse entsoeng ka motsoako o thehiloeng holim'a carbon le ho matlafatsoa ke carbon fiber le lihlahisoa tsa eona (carbon fiber preform). E na le inertia ea carbon le matla a phahameng a carbon fiber. E na le thepa e ntle ea mochini, ho hanyetsa mocheso, ho hanyetsa kutu, ho fokotsa likhohlano le litšobotsi tsa motlakase le tsa motlakase.

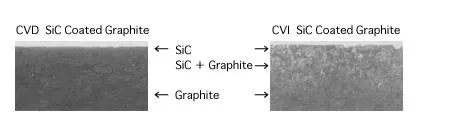

CVD-SiCbarbotage na le litšobotsi tsa sebopeho junifomo, thepa diseke ee, phahameng mocheso hanyetsa, khanyetso oxidation, bohloeki phahameng, acid & alkali ho hanyetsa le reagent manyolo, le thepa e tsitsitseng 'meleng le lik'hemik'hale.

Ha ho bapisoa le lisebelisoa tse phahameng tsa graphite, graphite e qala ho oxidize ho 400C, e tla baka tahlehelo ea phofo ka lebaka la oxidation, e leng se bakang tšilafalo ea tikoloho ho lisebelisoa tsa peripheral le likamore tsa vacuum, le ho eketsa litšila tsa tikoloho e hloekileng.

Leha ho le joalo, ho roala ha SiC ho ka boloka botsitso ba 'mele le lik'hemik'hale ka likhato tse 1600, E sebelisoa haholo indastering ea sejoale-joale, haholo indastering ea semiconductor.

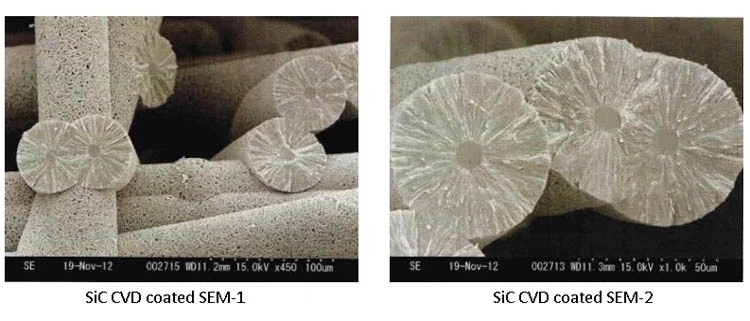

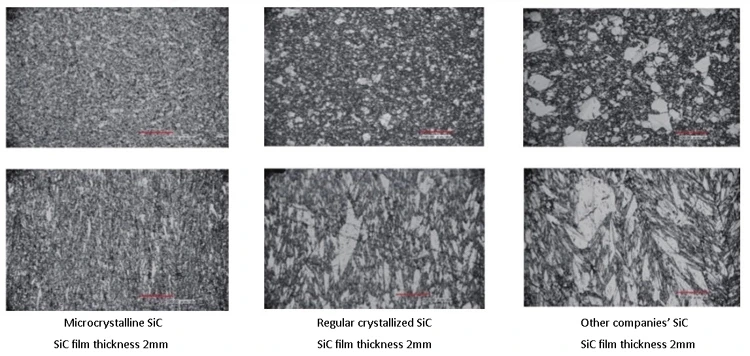

Khamphani ea rona e fana ka lits'ebeletso tsa ts'ebetso ea ho roala ka SiC ka mokhoa oa CVD holim'a graphite, li-ceramics le lisebelisoa tse ling, e le hore likhase tse khethehileng tse nang le k'habone le silicon li sebetsane le mocheso o phahameng ho fumana limolek'hule tsa SiC tse hloekileng, limolek'hule tse behiloeng holim'a lisebelisoa tse koahetsoeng, li etsa lera la tšireletso la SIC. SIC e entsoeng e tlamahane ka thata ho setsi sa graphite, e fana ka lisebelisoa tse khethehileng tsa graphite, kahoo e etsa hore bokaholimo ba graphite bo kopane, bo se ke ba e-ba le Porosity, ho hanyetsa mocheso o phahameng, ho hanyetsa kutu le ho hanyetsa oxidation.

Lintlha tse ka sehloohong:

1. Ho hanyetsa mocheso o phahameng oa oxidation:

khanyetso ea oxidation e ntse e le ntle haholo ha mocheso o le holimo ho 1600 C.

2. Bohloeki bo phahameng: bo entsoeng ka ho kenngoa ha mouoane oa lik'hemik'hale tlas'a boemo bo phahameng ba mocheso oa chlorination.

3. Ho hanyetsa khoholeho ea mobu: boima bo phahameng, bokaholimo bo kopanetsoeng, likaroloana tse ntle.

4. Ho hanyetsa kutu: acid, alkali, letsoai le li-reagents tse phelang.

Lintlha tse ka sehloohong tsa CVD-SIC Coatings:

| SiC-CVD | ||

| Botenya | (g/cc)

| 3.21 |

| Matla a flexural | (Mpa)

| 470 |

| Katoloso ea mocheso | (10-6/K) | 4

|

| Thermal conductivity | (W/mK) | 300

|