Khamphani ea rona e ikemiselitse ho sebetsa ka bots'epehi, ho sebeletsa bareki bohle ba rona, le ho sebetsa ka mahlale a macha le mochini o mocha kamehla bakeng sa thekiso e chesang ea China Mirror Polish Silicon Carbide Nitride Ceramic Rod Si3n4 Ceramic Tube, Na u ntse u batla sehlahisoa sa boleng bo holimo se lumellanang le setšoantšo sa hau se setle ha u ntse u atolosa sehlahisoa kapa litšebeletso tsa hau? Leka litharollo tsa rona tsa boleng bo holimo. Khetho ea hau e tla ipaka e le bohlale!

Khamphani ea rona e ikemiselitse ho sebetsa ka botšepehi, ho sebeletsa bareki bohle ba rona, le ho sebetsa ka theknoloji e ncha le mochini o mocha kamehlaChina Silicon Nitride, Molamu oa Si3n4, Re 'nile ra tsitlallela ho fetoha ha tharollo, re sebelisitse lichelete tse ntle le basebetsi ho ntlafatsa theknoloji, le ho thusa ntlafatso ea tlhahiso, ho finyella litlhoko tsa litebello tse tsoang linaheng tsohle le libaka.

Sintered Silicon Carbide Ceramic Bushing

Sintered silicon carbide (SSIC)e hlahisoa ho sebelisoa phofo e ntle haholo ea SiC e nang le li-additives tsa sintering. E sebetsoa ka ho sebelisa mekhoa ea ho etsa e tloaelehileng bakeng sa li-ceramics tse ling 'me e siiloe ka 2,000 ho 2,200 ° C moeeng oa khase ea inert. Hape hammoho le liphetolelo tse ntle, tse nang le boholo ba lijo-thollo <5 um, liphetolelo tse mahoashe tse nang le boholo ba lijo-thollo ho fihlela ho 1.5 mm li fumaneha.

SSIC e khetholloa ka matla a phahameng a lulang a batla a sa fetohe ho fihlela mocheso o phahameng haholo (hoo e ka bang 1,600 ° C), a boloka matla ao ka nako e telele!

Melemo ea sehlahisoa:

Ho hanyetsa mocheso o phahameng oa oxidation

E babatsehang Corrosion resistance

Khahlano e ntle ea Abrasion

High coefficient ea mocheso conductivity

Ho itšehla thajana, boima bo tlase

Boima bo phahameng

Moralo o hlophisitsoeng.

Thepa ea tekheniki:

| Lintho | Yuniti | Lintlha |

| Ho thatafala | HS | ≥110 |

| Porosity Rate | % | <0.3 |

| Botenya | g/cm3 | 3.10-3.15 |

| E hatellang | MPa | >2200 |

| Matla a Fractural | MPa | >350 |

| Coefficient ea katoloso | 10/°C | 4.0 |

| Litaba tsa Sic | % | ≥99 |

| Thermal conductivity | W/mk | >120 |

| Elastic modulus | GPA | ≥400 |

| Mocheso | °C | 1380 |

-

Litheko tse ngata ka ho fetisisa tsa carbon graphite block tse sebelisetsoang ...

-

Antimony e kentsoeng tiiso ea graphite carbon ring

-

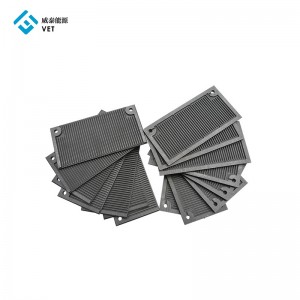

Fuel Cell Grade Graphite Plate, Carbon bipolar ...

-

Carbon Graphite Block, graph e hatellang ea isostatic...

-

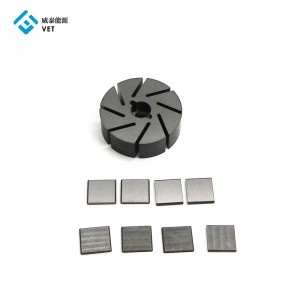

Carbon graphite rotor ea rekisoa

-

Carbon graphite vane bakeng sa lipompo tsa busch vacuum

-

Liphanele tsa pompo ea carbon bakeng sa ho etsa vacuum & vac...

-

Mehele ea khabone ka litiiso tsa mochini, selikalikoe sa graphite ...

-

Carbon seal ring , Graphite Piston Rings bakeng sa Ro...

-

Feme ea China bakeng sa China Sintered Silicon Carbid...

-

Clay graphite crucible otational Molding mofuta

-

Letlapa le kopaneng la electrode bakeng sa vanadium redox fl...

-

Customable cheap reusable High Pure Graphite Graphi...

-

Lintho tse futhumatsang tsa graphite, likarolo tsa carbon f ...

-

Sefuthumatsi sa Graphite se ikhethileng bakeng sa Semiconductor Si...

-

Customized Melting SIC Ingot Mould,Silico...