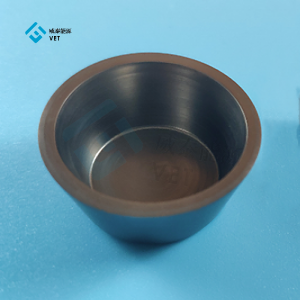

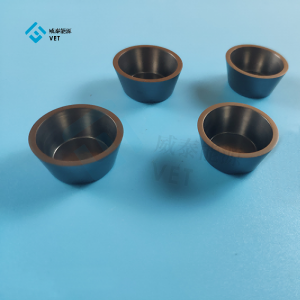

Tshebetso e phahamengtantalum carbide e koahetsoengporous graphite ke thepa e tsoetseng pele e nang le ts'ebetso e babatsehang. E kopanya melemo eaho roala ha tantalum carbidele porous graphite matrix, e bonts'ang litšobotsi tse ntle haholo le bokhoni bo pharaletseng ba ts'ebeliso.

Boitsebiso bona bo na le likarolo tse 'maloa tsa bohlokoa. Ea pele, theho roala ha tantalum carbidee fana ka thepa e babatsehang matla a mochine le ho hanyetsa kutu, ho sireletsa ka katleho porous graphite matrix, le ho lelefatsa bophelo ba tšebeletso ea thepa. Ea bobeli, porous graphite matrix e na le sebopeho se nang le li-porous tse ngata, tse fanang ka palo e kholo ea micropores le mesopores, e leng se fanang ka sebaka se seholo se khethehileng sa holimo le ts'ebetso e babatsehang ea adsorption.

Ho roala ha TaC ke mofuta oa tantalum carbide (TaC) e lokiselitsoeng ke theknoloji ea ho beha mouoane oa 'mele, e na le litšobotsi tse latelang:

1. Boima bo phahameng: boima ba ho roala ha TaC bo phahame, hangata bo ka fihla ho 2500-3000HV, ke seaparo se thata se babatsehang.

2. Ho hanyetsa ho roala: Ho roala ha TaC ho thata haholo, ho ka fokotsang ho senyeha ha likarolo tsa mochine nakong ea tšebeliso.

3. Ho hanyetsa mocheso o phahameng: Ho roala ha TaC ho ka boela ha boloka ts'ebetso ea eona e babatsehang tlas'a tikoloho ea mocheso o phahameng.

4. Botsitso bo botle ba lik'hemik'hale: Ho roala ha TaC ho na le botsitso bo botle ba lik'hemik'hale 'me ho ka hanela liphetoho tse ngata tsa lik'hemik'hale, tse kang li-acids le metheo.

| 碳化钽涂层物理特性物理特性 Lintho tse bonahalang tsa TaC ho roala | |

| 密度/ Ho teteana | 14.3 (g/cm³) |

| 比辐射率 / Mosi o kgethehileng | 0.3 |

| 热膨胀系数 / Coefficient ea katoloso ea mocheso | 6.3 10-6/K |

| 努氏硬度/ Ho thatafala (HK) | 2000 HK |

| 电阻 / Khanyetso | 1×10-5 Ohm*cm |

| 热稳定性 / Ho tsitsa ha mocheso | <2500℃ |

| 石墨尺寸变化 / Liphetoho tsa boholo ba graphite | -10 ~ 20um |

| 涂层厚度 / Botenya ba ho roala | ≥20um boleng bo tloaelehileng (35um±10um) |

Ningbo VET Energy Technology Co., Ltd ke khoebo ea theknoloji e phahameng e shebaneng le tlhahiso le thekiso ea thepa ea boleng bo holimo, thepa le theknoloji e koahelang graphite, silicon carbide, ceramics, kalafo ea holim'a metsi joalo-joalo. Lihlahisoa li sebelisoa haholo ho photovoltaic, semiconductor, matla a macha, metallurgy, joalo-joalo.

Sehlopha sa rona sa tekheniki se tsoa litsing tse phahameng tsa lipatlisiso tsa lapeng, se ka u fa litharollo tsa lisebelisoa tse eketsehileng bakeng sa hau.

Re u amohela ka mofuthu hore u etele feme ea rona, ha re buisaneng ka ho eketsehileng!

-

Good Wear Resistance le Corrosion Resistance T...

-

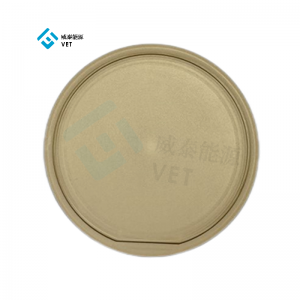

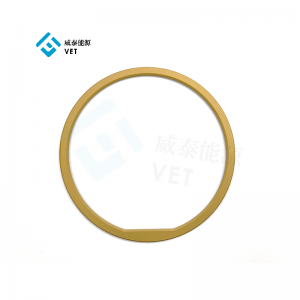

Bohloeki bo Phahameng Tantalum Carbide Coated Ring

-

Mocheso o Phahameng O tsitsitseng Khalase ea khabone ea khabone

-

K'habone ea Khalase e Iketselitsoeng Bakeng sa Lab...

-

Bafepedi ba China bakeng sa Tataiso e Kgethehileng ya TaC...

-

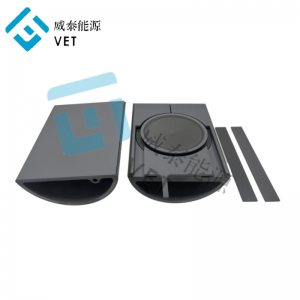

Karolo e ka holimo le e ka tlaase ea Graphite Half-moon ea Si...