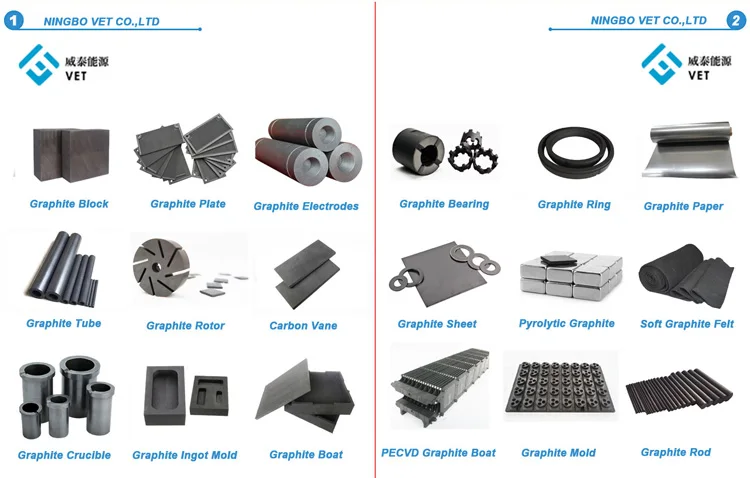

Likaroloana:

- Mabele a matle

- Sebopeho sa homogeneous

- Boima bo phahameng

- Excellent mogote conductivity

- Matla a phahameng a mochine

- Ts'ebetso e nepahetseng ea motlakase

- Ho koloba ho fokolang ho litšepe tse qhibilihisitsoeng

Boholo bo Tloaelehileng:

| Li-blocks | Bolelele x Bophara x Botenya (mm) 200x200x70, 250x130x100, 300x150x100, 280x140x110, 400x120x120, 300x200x120, 780x210x120, 330x260x120, 650x200x135, 650x210x135, 380x290x140, 500x150x150, 350x70x30, 350x30x30 400x170x160, 550x260x160, 490x300x180, 600x400x200, 400x400x400 |

| Lipotoloho | Diameter (mm): 60, 100, 125, 135, 150, 200, 250, 300, 330, 400, 455 Botenya (mm): 100, 135, 180, 220, 250, 300, 450 |

* Litekanyo tse ling lia fumaneha ka kopo.

Litlhaloso:

| Litlhaloso | Yuniti | Boleng |

| Boima ba Bongata | g/cc | 1.70 - 1,85 |

| Matla a Khatellang | MPa | 30 - 80 |

| Matla a Kobehang | MPa | 15-40 |

| Bothata ba lebopo | 30 - 50 | |

| Khanyetso e Itseng | micro ohm.m | 8.0 - 15.0 |

| Molora (Kreiti e Tlwaelehileng) | % | 0.05 - 0.2 |

| Molora (hloekisitsoe) | ppm | 30 - 50 |

Lisebelisoa:

- Li-molds, li-chute, li-sleeve, sheathes, linings, joalo-joalo ka mekhoa e tsoelang pele ea ho lahla bakeng sa ho etsa tšepe e bōpehileng, tšepe e entsoeng ka tšepe, koporo, aluminium.

- Li-mold tsa sintering bakeng sa li-carbides tse samenteng le lisebelisoa tsa daemane.

- Sintering hlobo bakeng sa likarolo tsa elektroniki.

- Electrodes bakeng sa EDM.

- Licheso, lithebe tsa mocheso, li-crucibles, liketsoana ka har'a libopi tse ling tsa indasteri (joalo ka libopi tsa ho hula silicon ea monocrystalline kapa likhoele tsa optical).

- Li-bearings le litiiso ka har'a lipompo, li-turbine le li-motor.

- joalo joalo.

-

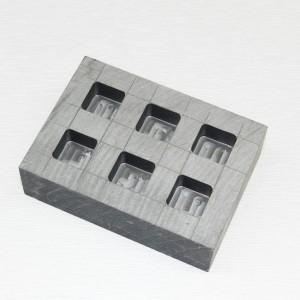

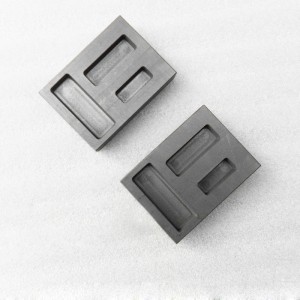

150g ea khauta ea Graphite Ingot Mold

-

10oz khauta ho lahla Graphite Ingot Mold

-

0.5Lb Copper Graphite Ingot Mold

-

0.25oz silevera ea Graphite Ingot Mold

-

1.75oz khauta Graphite Ingot Mold

-

1kg khauta Graphite Ingot Mold

-

1oz Gold Bar Graphite Ingot Mold

-

3Kg Gold Bar Graphite Ingot Mold

-

Lesela le kentsoeng la Carbon Fiber, le entsoeng ka khabone ...

-

Motsoako oa carbon fiber o ikutloa acf bakeng sa ho lahloa ...

-

Antimony Alloy Graphite Bushings/ Ho beha

-

Theko e tlase China Manufacture of Carbon Graphi...

-

Carbon block theko e ntle ka ho fetisisa ea sebōpi sa arc