Inopisa munda system yepolycrystalline ingot vira

Iyo inopisa yemunda sisitimu yepolycrystalline ingot yekukanda vira ndiyo yakakosha midziyo yepolycrystalline ingot inokandira muindasitiri yephotovoltaic. Zvigadzirwa zvekambani zvinonyanya zvinosanganisira denga, kupisa muviri, ndiro yekuvhara, ndiro yekudzivirira uye zvimwe zvikamu

| siriyero nhamba | zita rechigadzirwa | Sample dhizaini yezvikamu zvechigadzirwa | chigadzirwa chepamusoro | main performance index |

| 1 | Top plate | Quasi-matatu-dimensional chimiro, yakakwira kabhoni fiber yemukati, uchishandisa inopisa kudzvanya uye resin impregnation densification process, pfupi kugadzirwa kutenderera, ma mechanic zvimiro zvehumwe density pane isostatic pressure graphite zvinhu. | VET: Density 1.3g / cm3, kusimba simba :180Mpa, kukotama simba :150Mpa Vanokwikwidza: 1.35g / cm3, kusimba simba ≥180MPa, kukotama simba ≥140MPa

| |

| 2 | Chivharo ndiro | Quasi-matatu-dimensional chimiro, yakakwira kabhoni fiber yemukati, uchishandisa inopisa kudzvanya uye resin impregnation densification process, pfupi yekugadzira kutenderera, ine yakanaka yekupisa yekuvharisa kuita, hupenyu hurefu hwebasa uye zvimwe zvakanaka. | VET: Density 1.4g / cm3, kusimba simba :208Mpa, kukombama simba :195Mpa Vanokwikwidza: 1.45g / cm3, kusimba simba ≥200MPa, kukotama simba ≥160MPa

| |

| 3 | Guard ndiro | Quasi-matatu-dimensional chimiro, yakakwira kabhoni fiber yemukati, uchishandisa inopisa kudzvanya uye resin impregnation densification process, pfupi kugadzirwa kutenderera, ma mechanic zvimiro zve density yakafanana pane yakachena vapor deposition zvigadzirwa. | VET: Density 1.4g / cm3, kusimba simba :208Mpa, kukombama simba :195Mpa Vanokwikwidza: 1.45g / cm3, kusimba simba ≥200MPa, kukotama simba ≥160MPa

| |

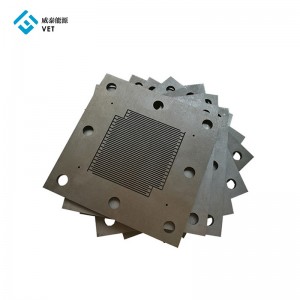

| 4 | Kupisa muviri | Kuburikidza neiyo microstructure dhizaini, chigadzirwa resistivity inovandudzwa, quasi-matatu-dimensional chimiro, yakakwira kabhoni fiber yemukati, uchishandisa inopisa kudzvanya uye resin impregnation densification process, pfupi kugadzirwa kutenderera, density yakafanana, zvimiro zvayo zvemuchina zviri nani pane yakachena vapor deposition zvigadzirwa, hupenyu hurefu hwebasa. | VET: Density 1.5g/cm3, Kupeta simba: 220MPa Kuramba: 18-22x10-5Ω*m Vanokwikwidza: 1.5g / cm3, Kupeta simba: 210MPa Kuramba: 18-22x10-5Ω*m

| |

| 5 | fastener | Kuburikidza neiyo microstructure dhizaini, iyo interlayer density yechigadzirwa inovandudzwa, shanduko yekuchinja inofanana pakati pematanho, uye interlayer bonding simba rakanaka. Iyo yekusiyanisa pressure vapor deposition densification process inotambirwa, uye densification iri yunifomu, uye chiyero chechigadzirwa chakagadzirwa chakakwira. | VET: Density 1.45g/cm3, simba rekukotama: 160Mpa; Vanokwikwidza: Density 1.4g / cm3, kukotama simba: 130MPa

| |

| 6 | Insulation strip | Gamuchira akasiyana maitiro ekurapwa kwepamusoro, kuderedza guruva muchoto, nyore disassembly choto, hupenyu hurefu hwebasa rezvigadzirwa. | VET: Density ≤0.16 g/cm3 Mukwikwidzi: Density ≤ 0.18g / cm3

|

-

2019 Yakakwirira mhando Tsika Rudzi Size Fkm Rubber ...

-

100% Chekutanga Factory China High Purity Graphit...

-

Mutengo Wemufekitari weChina Graphite Bipolar Plate ...

-

Fekitari Yakananga kupa China 12V 200ah RV uye ...

-

Mutengo Sheet yeChina Graphite Crucible yeMel...

-

Factory Outlets China Self-Lubricating Graphite...