High-performancetantalum carbide coatedporous graphite chinhu chepamberi chine kuita kwakanakisa. Inobatanidza zvakanakiratantalum carbide coatinguye porous graphite matrix, inoratidza hunhu hwakanakisa uye yakafara mukana wekushandisa.

Nyaya iyi ine zvinhu zvakawanda zvakakosha. Kutanga, thetantalum carbide coatinginopa zvinhu zvakanakisa simba remechani uye corrosion kuramba, zvino chengetedza porous graphite matrix, uye inowedzera hupenyu hwesevhisi yezvinhu. Chechipiri, iyo porous graphite matrix ine yakanyanya porous chimiro, ichipa huwandu hukuru hwe micropores uye mesopores, iyo inopa iyo yakakura chaiyo nzvimbo uye yakanakisa adsorption performance.

TaC coating imhando ye tantalum carbide (TaC) yekubikira yakagadzirwa nemuviri vapor deposition tekinoroji, ine zvinotevera maitiro:

1. Kuomarara kwepamusoro: Kuomarara kweTaC kwakakwira, kazhinji kunogona kusvika 2500-3000HV, iko kuomarara kwakaoma.

2. Pfeka kuramba: TaC coating inonyanya kupfeka-inodzivirira, iyo inogona kunyatso kudzikisa kupfeka uye kukuvadzwa kwemechani zvikamu panguva yekushandiswa.

3. Yakanaka yakakwirira tembiricha kuramba: TaC coating inogonawo kuchengetedza kuita kwayo kwakanakisa pasi pemamiriro ekushisa kwepamusoro.

4. Kugadzikana kwakanaka kwemakemikari: TaC yakavhara ine yakanaka kugadzikana kwemakemikari uye inogona kurwisa maitiro akawanda emakemikari, akadai seasidhi uye mabhesi.

| 碳化钽涂层物理特性物理特性 Zvenyama zve TaC coating | |

| 密度/ Density | 14.3 (g/cm³) |

| 比辐射率 / Chaiyo emssivity | 0.3 |

| 热膨胀系数 / Thermal yekuwedzera coefficient | 6.3 10-6/K |

| 努氏硬度/ Kuoma (HK) | 2000 HK |

| 电阻 / Kupikisa | 1×10-5 Om*cm |

| 热稳定性 / Thermal kugadzikana | <2500℃ |

| 石墨尺寸变化 / Graphite saizi shanduko | -10 ~ -20um |

| 涂层厚度 / Coating ukobvu | ≥20um yakajairika kukosha (35um±10um) |

Ningbo VET Energy Technology Co., Ltd ibhizimusi repamusoro-soro rinotarisa kugadzirwa uye kutengesa kwezvinhu zvepamusoro-soro, zvigadzirwa uye tekinoroji inovhara graphite, silicon carbide, ceramics, kurapwa kwepamusoro uye zvichingodaro. Zvigadzirwa zvinoshandiswa zvakanyanya mu photovoltaic, semiconductor, simba idzva, metallurgy, nezvimwewo.

Chikwata chedu chehunyanzvi chinobva kumasangano epamusoro ekutsvagisa dzimba, anogona kukupa mamwe hunyanzvi zvigadziriso zvekushandisa kwauri.

Tikugashirei noushamwari kuti ushanyire fekitari yedu, ngativei neimwe hurukuro!

-

Good Wear Resistance uye Corrosion Resistance T...

-

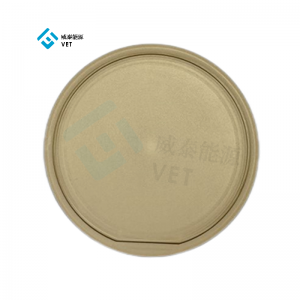

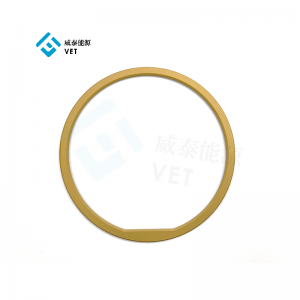

High Pure Tantalum Carbide Coated Ring

-

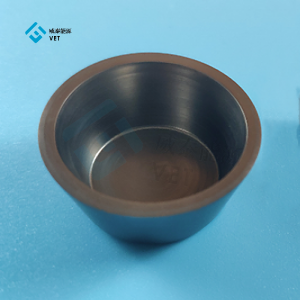

Yakakwira Tembiricha Kugadzikana Girazi kabhoni crucible

-

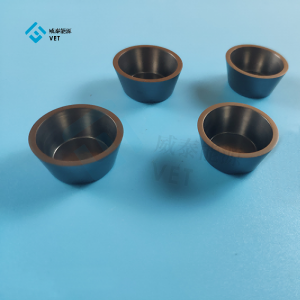

Yakagadzirirwa Girazi Carbon Crucible YeRabhoritari...

-

China Suppliers for Customized TaC Coated Guide...

-

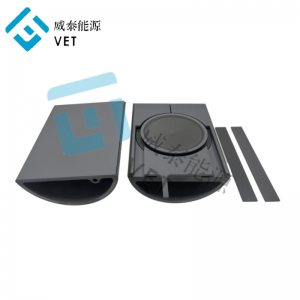

Pamusoro uye Pazasi Graphite Hafu-mwedzi Chikamu cheSi...