Hunhu hwakanaka hunouya pakutanga; service iri pamberi; sangano kushandira pamwe” ndihwo huzivi hwebhizinesi redu hunogara huchicherechedzwa nekuteverwa nekambani yedu nemutengo wakachipa China High Temperature Resistance Molybdenum Graphite Crucible Metal Melting Pot, Kuona anotenda!

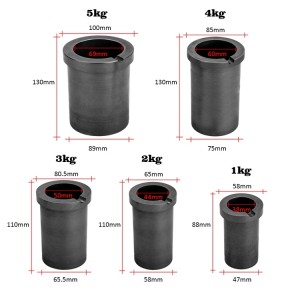

Hunhu hwakanaka hunouya pakutanga; service iri pamberi; sangano kushandira pamwe” ndihwo huzivi hwebhizinesi hwedu hunogara huchicherechedzwa nekuteverwa nekambani yeduChina Molybdenum Crucible, Crucibles Kutengeswa, Isu tinopa sevhisi ine ruzivo, mhinduro nekukurumidza, kuendesa panguva, mhando yepamusoro uye mutengo wakanaka kune vatengi vedu. Kugutsikana uye kiredhiti yakanaka kune wese mutengi ndiyo yedu yekutanga. Isu tinotarisa pane zvese zvekugadzirisa maodha kune vatengi kusvika vawana zvakachengeteka uye zvine ruzha zvigadzirwa zvine yakanaka logistics sevhisi uye mutengo wehupfumi. Zvichienderana neizvi, zvinhu zvedu zvinotengeswa zvinotengeswa zvakanyanya munyika dziri muAfrica, Mid-East neSoutheast Asia. Tichitevedzera huchenjeri hwebhizinesi hwe'mutengi kutanga, tungamira mberi', tinogamuchira nemoyo wese vatengi vanobva kumusha nekune dzimwe nyika kuti vashande nesu.

Carbon / carbon composite(zvino zvinozonzi "C / C kana CFC") imhando yezvakaumbwa zvinhu izvo zvakavakirwa pakabhoni uye inosimbiswa nekabhoni fiber uye zvigadzirwa zvayo (carbon fiber preform). Iine zvose inertia yekabhoni uye simba rakakwirira re carbon fiber. Iyo ine yakanaka yemagetsi zvivakwa, kupisa kupisa, corrosion resistance, friction damping uye thermal uye magetsi conductivity maitiro.

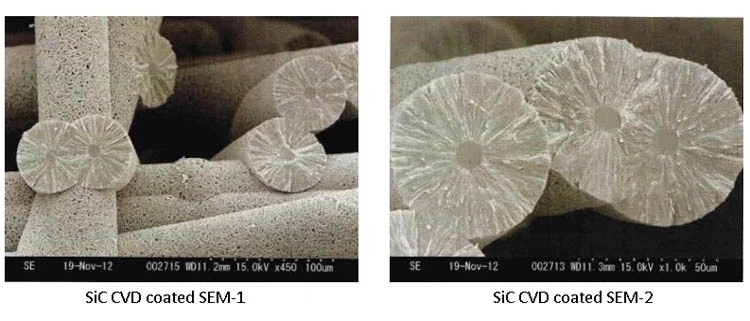

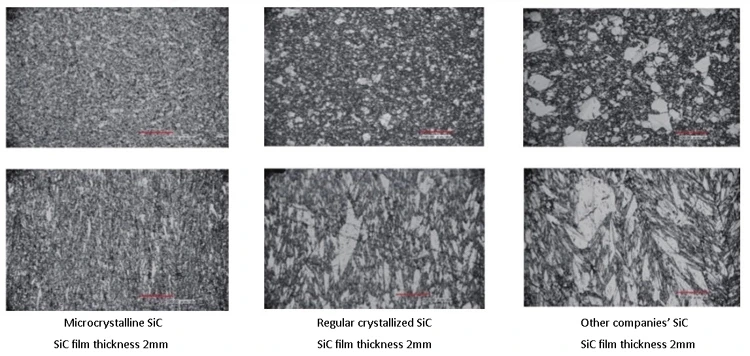

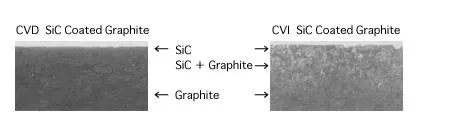

CVD-SiCCoating ine hunhu hwechimiro chakafanana, compact material, yakakwirira tembiricha kuramba, oxidation kuramba, kuchena kwakanyanya, acid & alkali kuramba uye organic reagent, ine yakagadzikana yemuviri nemakemikari zvinhu.

Zvichienzaniswa nepamusoro-kuchena graphite zvinhu, graphite inotanga oxidize pa 400C, iyo inokonzera kurasikirwa kwehupfu nekuda kweoxidation, zvichiita kuti kusvibiswa kwezvakatipoteredza kune zvigadzirwa zveparipheral uye vacuum chambers, uye kuwedzera kusvibiswa kwepamusoro-kuchena kwezvakatipoteredza.

Nekudaro, SiC coating inogona kuchengetedza kugadzikana kwemuviri uye kemikari pa1600 madhigirii, Inoshandiswa zvakanyanya muindasitiri yemazuva ano, kunyanya muindasitiri yesemiconductor.

Kambani yedu inopa SiC yekuvhara maitiro masevhisi neCVD nzira pamusoro pegraphite, ceramics uye zvimwe zvinhu, kuitira kuti akakosha magasi ane kabhoni uye silicon aite pakupisa kwepamusoro kuti awane kuchena kweSiC mamorekuru, mamorekuru akaiswa pamusoro pezvinhu zvakavharwa, achigadzira SIC yekudzivirira layer. Iyo SIC yakaumbwa inosungirirwa zvakasimba kune iyo graphite base, ichipa iyo graphite base yakakosha zvivakwa, nekudaro ichiita pamusoro peiyo graphite compact, Porosity-isina, yakakwirira tembiricha kuramba, corrosion kuramba uye oxidation kuramba.

Main features:

1. High tembiricha oxidation kuramba:

iyo oxidation kuramba ichiri yakanaka kwazvo kana tembiricha yakakwira kusvika 1600 C.

2. Kuchena kwepamusoro: yakagadzirwa nemakemikari vapor deposition pasi pekushisa kwakanyanya kweklorination mamiriro.

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, munyu uye organic reagents.

Zvinonyanya Kutaurwa zveCVD-SIC Coatings:

| SiC-CVD | ||

| Density | (g/cc)

| 3.21 |

| Flexural simba | (Mpa)

| 470 |

| Kuwedzera kupisa | (10-6/K) | 4

|

| Thermal conductivity | (W/mK) | 300

|