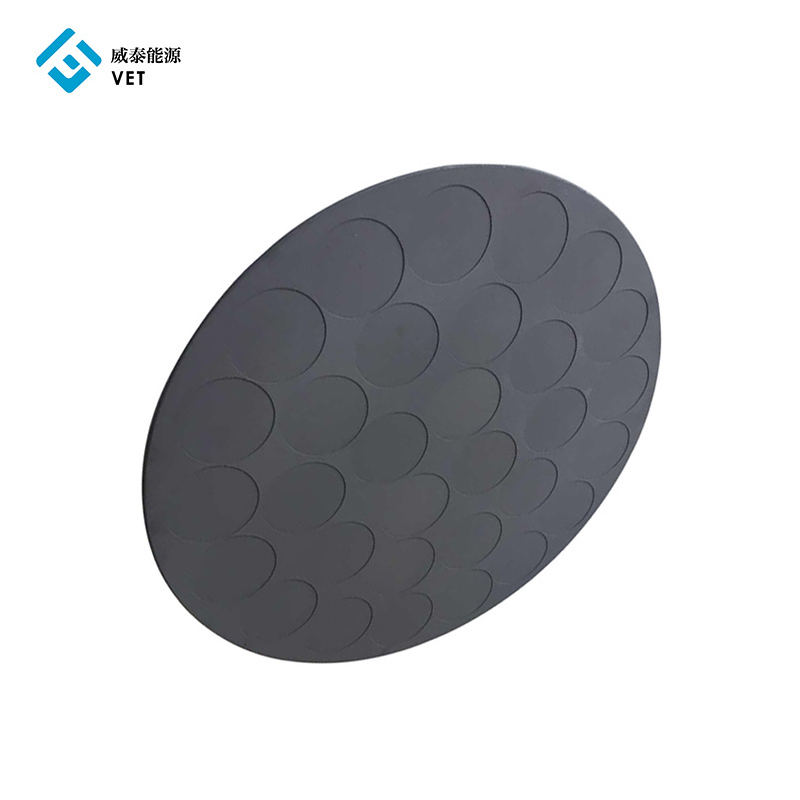

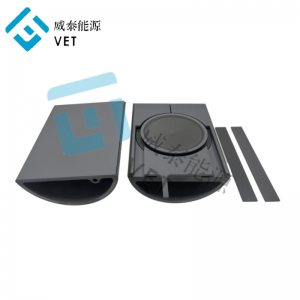

The VET Energy SiC Coated MOCVD Susceptor is a high-performance product engineered for consistent and reliable performance in wafer processing applications. Featuring a superior SiC coating, it offers exceptional heat resistance, thermal uniformity, and corrosion resistance. Ideal for MOCVD equipment, this silicon carbide coated susceptor ensures optimal wafer growth and extended equipment lifespan.

Product Features:

1. High-temperature oxidation resistance up to 1700℃: Our SiC coating provides exceptional thermal stability, even in the most demanding MOCVD environments.

2. High purity and thermal uniformity: The silicon carbide susceptor guarantees minimal impurities and consistent heating across the wafer, ensuring superior crystal quality.

3. Excellent corrosion resistance: Resistant to acids, alkalis, salts, and organic reagents, our susceptor maintains its integrity in various chemical environments.

4. High hardness, dense surface, and fine particles: These properties contribute to a longer service life and enhanced durability.

Our CVD silicon carbide coated Product Benefits and Applications

MOCVD susceptors deliver significant advantages in semiconductor manufacturing. The SiC coating enhances wafer quality, reduces defects, and optimizes production efficiency. VET Energy supplies a wide range of silicon carbide products tailored to the specific needs of the semiconductor and photovoltaic industries.

Product Customization and Technical Support

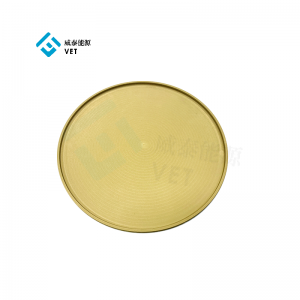

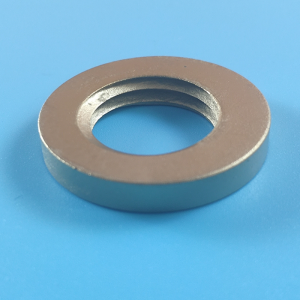

As a leading manufacturer of silicon carbide and graphite products, VET Energy offers customized solutions with various coatings like SiC, TaC, glassy carbon, and pyrolytic carbon. Our experienced team can provide expert guidance and support for your specific application.

Ningbo VET Energy Technology Co., Ltd is a high-tech enterprise focusing on the development and production of high-end advanced materials, the materials and technology including graphite, silicon carbide, ceramics, surface treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc., these products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc.

Our technical team comes from top domestic research institutions, and have developed multiple patented technologies to ensure product performance and quality, can also provide customers with professional material solutions.