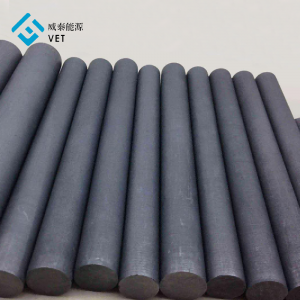

Vet-China Silicon Carbide Ceramic Coating is a high-performance protective coating made of extremely hard and wear-resistant silicon carbide (SiC) material, which provides excellent chemical corrosion resistance and high-temperature stability. These characteristics are crucial in semiconductor production, so Silicon Carbide Ceramic Coating is widely used in key components of semiconductor manufacturing equipment.

The specific role of Vet-China Silicon Carbide Ceramic Coating in semiconductor production is as follows:

Enhance equipment durability: Silicon Carbide Ceramic Coating Silicon Carbide Ceramic Coating provides excellent surface protection for semiconductor manufacturing equipment with its extremely high hardness and wear resistance. Especially in high-temperature and highly corrosive process environments, such as chemical vapor deposition (CVD) and plasma etching, the coating can effectively prevent the surface of the equipment from being damaged by chemical erosion or physical wear, thereby significantly extending the service life of the equipment and reducing downtime caused by frequent replacement and repair.

Improve process purity: In the semiconductor manufacturing process, tiny contamination may cause product defects. The chemical inertness of Silicon Carbide Ceramic Coating allows it to remain stable under extreme conditions, preventing the material from releasing particles or impurities, thereby ensuring the environmental purity of the process. This is particularly important for manufacturing steps that require high precision and high cleanliness, such as PECVD and ion implantation.

Optimize thermal management: In high-temperature semiconductor processing, such as rapid thermal processing (RTP) and oxidation processes, the high thermal conductivity of Silicon Carbide Ceramic Coating enables uniform temperature distribution inside the equipment. This helps reduce thermal stress and material deformation caused by temperature fluctuations, thereby improving product manufacturing accuracy and consistency.

Support complex process environments: In processes that require complex atmosphere control, such as ICP etching and PSS etching processes, the stability and oxidation resistance of Silicon Carbide Ceramic Coating ensure that the equipment maintains stable performance in long-term operation, reducing the risk of material degradation or equipment damage due to environmental changes.

|

CVD SiC薄膜基本物理性能 Basic physical properties of CVD SiC coating |

|

|

性质 / Property |

典型数值 / Typical Value |

|

晶体结构 / Crystal Structure |

FCC β phase 多晶,主要为(111)取向 |

|

密度 / Density |

3.21 g/cm³ |

|

硬度 / Hardness |

2500 维氏硬度(500g load) |

|

晶粒大小 / Grain SiZe |

2~10μm |

|

纯度 / Chemical Purity |

99.99995% |

|

热容 / Heat Capacity |

640 J·kg-1·K-1 |

|

升华温度 / Sublimation Temperature |

2700℃ |

|

抗弯强度 / Flexural Strength |

415 MPa RT 4-point |

|

杨氏模量 / Young' s Modulus |

430 Gpa 4pt bend, 1300℃ |

|

导热系数 / Thermal Conductivity |

300W·m-1·K-1 |

|

热膨胀系数 / Thermal Expansion(CTE) |

4.5×10-6K-1 |

Warmly welcome you to visit our factory, let's have further discussion!