Description:

Silicon Carbide have the property of excellent resistant-corrosion, high mechanical strength, high thermal conductivity, good self-lubrication used as seal faces, bearings and tubes in spacecraft, machinery, metallurgy, printing and dyeing, foodstuff, pharmaceutical, auto industry and so on. When the sic faces are combined with graphite faces the friction is the smallest and they can be made into mechanical seals which are able to work in highest working requirements.

Silicon Carbide Basic Properties:

-Low density

-High thermal conductivity (close to aluminium)

-Good thermal shock resistance

-Liquid and gas proof

-High refractoriness(can be used at 1450℃ in air and 1800℃ in neutral atmosphere)

-It is not affacted by corrosion and do not wet with melted aluminium or melted zinc

-High hardness

-Low friction coefficient

-Abrasion resistance

-Resists to basic and strong acids

-Polisheable

-High mechanical strength

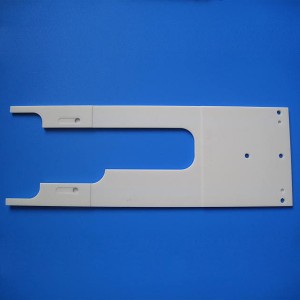

Silicon Carbide Application:

-Mechanical seals, bearings, thrust bearings, etc

-Rotating joints

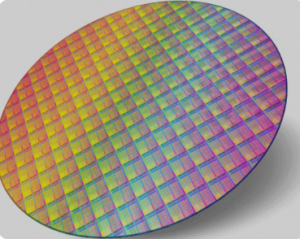

-Semiconductor and coating

-Pads Pump components

-Chemical components

-Mirrors for industrial laser systems.

- Continuous-flow reactors, heat exchangers, etc.

Feature

Silicon carbide is formed in two ways:

1)Pressureless sintered silicon carbide

After the pressureless sintered silicon carbide material is etched, the crystal phase diagram under the 200X optical microscope shows that the distribution and size of the crystals are uniform, and the largest crystal does not exceed 10μm.

2) Reaction sintered silicon carbide

After the reaction sintered silicon carbide chemically treats the flat and smooth section of the material, the crystal

distribution and size under the 200X optical microscope are uniform, and the free silicon content does not exceed 12%.

|

Technical Properties |

|||

|

Index |

Unit |

Value |

|

|

Material Name |

Pressureless Sintered Silicon Carbide |

Reaction Sintered Silicon Carbide |

|

|

Composition |

SSiC |

RBSiC |

|

|

Bulk Density |

g/cm3 |

3.15 ± 0.03 |

3 |

|

Flexural Strength |

MPa (kpsi) |

380(55) |

338(49) |

|

Compressive Strength |

MPa (kpsi) |

3970(560) |

1120(158) |

|

Hardness |

Knoop |

2800 |

2700 |

|

Breaking Tenacity |

MPa m1/2 |

4 |

4.5 |

|

Thermal Conductivity |

W/m.k |

120 |

95 |

|

Coefficient of Thermal Expansion |

10-6/°C |

4 |

5 |

|

Specific Heat |

Joule/g 0k |

0.67 |

0.8 |

|

Max temperature in air |

℃ |

1500 |

1200 |

|

Elastic Modulus |

Gpa |

410 |

360 |