Features:

· Excellent Thermal Shock Resistance

· Excellent Physical Shock Resistance

· Excellent Chemical Resistance

· Super High Purity

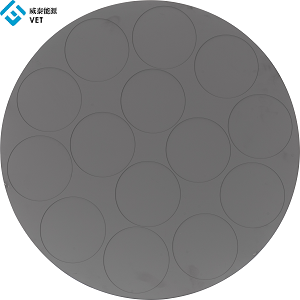

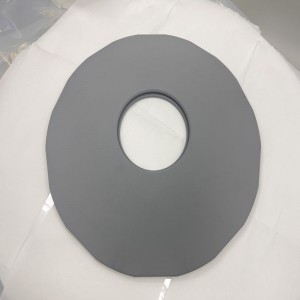

· Availability in Complex Shape

·Usable under Oxidizing Atmosphere

Application:

Product Features and Advantages:

1. Superior Thermal Resistance: With a high-purity SiC coating, the substrate withstands extreme temperatures, ensuring consistent performance in demanding environments such as epitaxy and semiconductor fabrication.

2. Enhanced Durability: The SiC coated graphite components are designed to resist chemical corrosion and oxidation, increasing the substrate’s lifespan compared to standard graphite substrates.

3. Vitreous Coated Graphite: The unique vitreous structure of the SiC coating provides excellent surface hardness, minimizing wear and tear during high-temperature processing.

4. High Purity SiC Coating: Our substrate ensures minimal contamination in sensitive semiconductor processes, offering reliability for industries that require stringent material purity.

5. Wide Market Application: The SiC coated graphite susceptor market continues to grow as demand for advanced SiC coated products in semiconductor manufacturing increases, positioning this substrate as a key player in both the graphite wafer carrier market and the silicon carbide coated graphite trays market.

Typical Properties of Base Graphite Material:

| Apparent Density: | 1.85 g/cm3 |

| Electrical Resistivity: | 11 μΩm |

| Flexural Strenth: | 49 MPa (500kgf/cm2) |

| Shore Hardness: | 58 |

| Ash: | <5ppm |

| Thermal Conductivity: | 116 W/mK (100 kcal/mhr-℃) |

|

CVD SiC薄膜基本物理性能 Basic physical properties of CVD SiC coating |

|

|

性质 / Property |

典型数值 / Typical Value |

|

晶体结构 / Crystal Structure |

FCC β phase 多晶,主要为(111)取向 |

|

密度 / Density |

3.21 g/cm³ |

|

硬度 / Hardness |

2500 维氏硬度(500g load) |

|

晶粒大小 / Grain SiZe |

2~10μm |

|

纯度 / Chemical Purity |

99.99995% |

|

热容 / Heat Capacity |

640 J·kg-1·K-1 |

|

升华温度 / Sublimation Temperature |

2700℃ |

|

抗弯强度 / Flexural Strength |

415 MPa RT 4-point |

|

杨氏模量 / Young' s Modulus |

430 Gpa 4pt bend, 1300℃ |

|

导热系数 / Thermal Conductivity |

300W·m-1·K-1 |

|

热膨胀系数 / Thermal Expansion(CTE) |

4.5×10-6K-1 |

VET Energy is the real manufacturer of customized graphite and silicon carbide products with different coatings like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc., can supply various customized parts for semiconductor and photovoltaic industry.

Our technical team comes from top domestic research institutions, can provide more professional material solutions for you.

We continuously develop advanced processes to provide more advanced materials, and have worked out an exclusive patented technology, which can make the bonding between the coating and the substrate tighter and less prone to detachment.

Warmly welcome you to visit our factory, let's have further discussion!