We’ve been also concentrating on bettering the things management and QC method in order that we could continue to keep terrific benefit inside the fiercely-competitive company for Renewable Design for Pure Graphite Block, Our hugely specialized process eliminates the component failure and offers our customers unvarying high quality, allowing us to control cost, plan capacity and maintain consistent on time delivery.

We’ve been also concentrating on bettering the things management and QC method in order that we could continue to keep terrific benefit inside the fiercely-competitive company for Density Rectangle Graphite Block, Isostatic Graphite Block, Pure Round Graphite Block, Our company, is always regarding quality as company’ s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

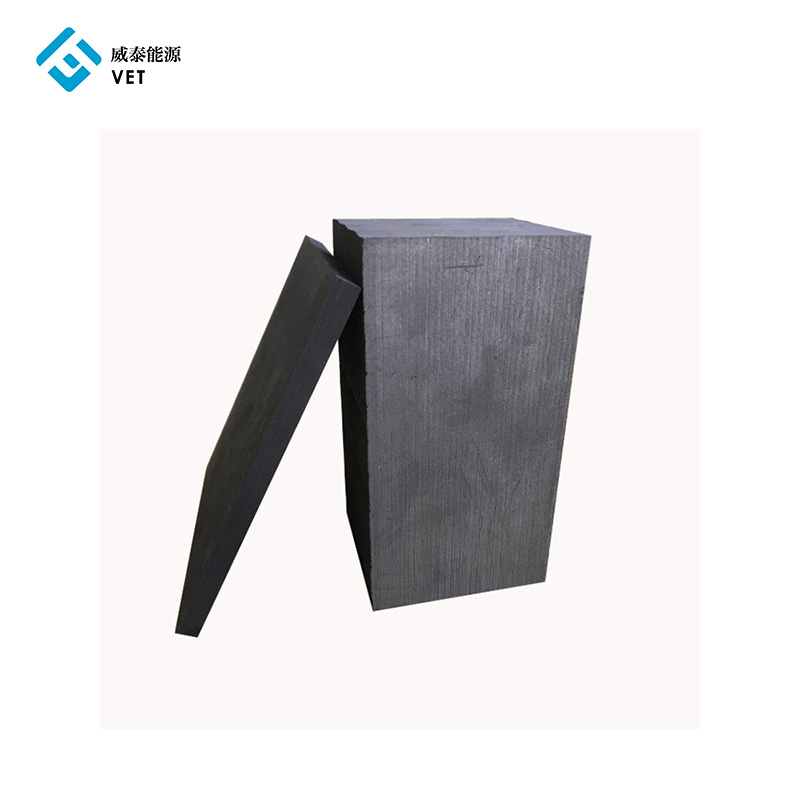

Graphite block is made from the domestic petroleum coke and widely used in the metallurgy, machinery, electronics and chemical industry, etc. The graphite block include molded, extruded, vibrated and isostatic.

Raw material ->Medium crushing / milling ->Screening -> dosing -> kneading-> vibrated molding->impregnation -> baking-> graphitization

| Item | Unit | Isostaic graphite |

| Grain size | μm | 5-22 |

| Bulk density | g/cm3 | 1.8-1.85 |

| Specific resistance | μΩ.m | ≤15 |

| Bending strength | Mpa | ≥40 |

| Compressive strength | Mpa | ≥85 |

| Shore hardness | ≥65 | |

| C.T.E.(100-600)℃ | 10-6/℃ | 4.0-5.2 |

| Modulus of elasticity | Gpa | 10-12.5 |

| Ash | % | ≤0.03% |

| High pure graphite | |||||

| Item | Unit | Baked twice | Baked three times | Baked four times | |

| Impregnated once | Impregnated twice | Impregnated three time | |||

| Grain size | Mm | ≤325 mesh | ≤325 mesh | ≤325 mesh | |

| Bulk density | g/cm3 | ≥1.68 | ≥1.78 | ≥1.85 | |

| Specific resistance | μΩ.m | ≤14 | ≤14 | ≤13 | |

| Bending strength | Mpa | ≥25 | ≥40 | ≥45 | |

| Compressive strength | Mpa | ≥50 | ≥60 | ≥65 | |

| Ash content | % | ≤0.15 | ≤0.1 | ≤0.05 | |

Features:

- Fine grain

- Homogeneous structure

- High density

- Excellent thermal conductivity

- High mechanical strength

- Proper electrical conductivity

- Minimum wettability to molten metals

Typical Sizes:

| Blocks | Length * Width * Thickness(mm) | ||||||

| 200*200*70,250*130*100,300*150*100,280*140*110,400*120*120, | |||||||

| 300*200*120,780*2109*120,330*260*120,650*200*135,650*210*135, | |||||||

| 380*290*140,500*150*150,350*300*150,670*300*150,400*170*160, | |||||||

| 550*260*160,490*300*180,600*400*200,400*400*400 | |||||||

| Rounds | Diameter(mm):60,100,125,135,150,200,250,300,330,400,455 | ||||||

| Tickness(mm):100,135,180,220,250,300,450 | |||||||

* Other dimensions are available on request.

Specifications:

| Specifications | Unit | Value | ||

| Bulk Density | g/cc | 1.70 – 1.85 | ||

| Compressive Strength | Mpa | 30 – 80 | ||

| Bending Strength | Mpa | 15 – 40 | ||

| Shore hardness | 30 – 50 | |||

| Specific Resistance | micro ohm.m | 8.0 – 15.0 | ||

| Ash (Normal Grade) | % | 0.05 – 0.2 | ||

| Ash (purified) | ppm | 30 – 50 | ||

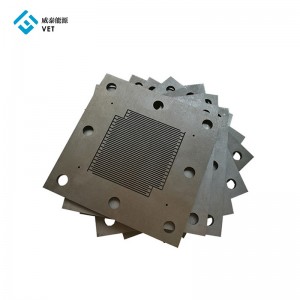

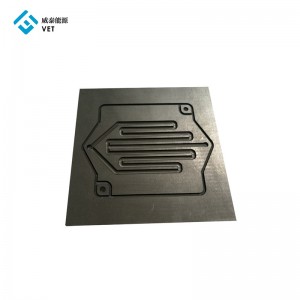

Applications:

- Molds, chutes, sleeves, sheathes, linings, etc. in continuous casting systems for making shaped steel, cast iron, copper, aluminum.

- Sintering molds for cemented carbides and diamond tools.

- Sintering molds for electronic components.

- Electrodes for EDM.

- Heaters, heat shields, crucibles, boats in some industrial furnaces (such as furnaces for pulling monocrystalline silicon or optical fibers).

- Bearings and seals in pumps, turbines and motors.

- and so on.

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

-

Reasonable price for Liquid flow used battery p...

-

Top Grade Degassing Graphite Rotor,Graphite Mix...

-

Rapid Delivery for China 800W Small Volume and ...

-

18 Years Factory China High Carbon Rectangular ...

-

electrolytic graphite plate Bipolar Plate for H...

-

Cheap PriceList for Factory Best Price 2000ml H...