We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for Quoted price for China High Temperature Resistance Green Silicon Carbide Abrasive Powder Black Silicon Carbide Polishing Powder, Customers’ benefit and gratification are normally our biggest intention. Remember to get in touch with us. Give us a probability, provide you with a surprise.

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for China Silicon Carbide, Sic, What is good price? We give customers with factory price. In the premise of good quality, efficiency ought to be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers’ requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products and solutions in time. Sincerely hope we could have long term business relationship.

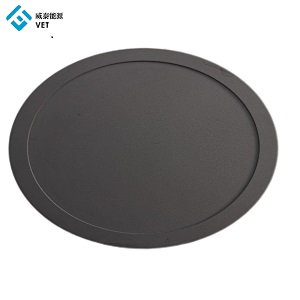

Product Description

Our company provides SiC coating process services by CVD method on the surface of graphite, ceramics and other materials, so that special gases containing carbon and silicon react at high temperature to obtain high purity SiC molecules, molecules deposited on the surface of the coated materials, forming SIC protective layer.

Main features:

1. High temperature oxidation resistance: the oxidation resistance is still very good when the temperature is as high as 1600 C.

2. High purity : made by chemical vapor deposition under high temperature chlorination condition.

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, salt and organic reagents.

Main Specifications of CVD-SIC Coating

|

SiC-CVD Properties |

||

| Crystal Structure | FCC β phase | |

| Density | g/cm ³ | 3.21 |

| Hardness | Vickers hardness | 2500 |

| Grain Size | μm | 2~10 |

| Chemical Purity | % | 99.99995 |

| Heat Capacity | J·kg-1 ·K-1 | 640 |

| Sublimation Temperature | ℃ | 2700 |

| Felexural Strength | MPa (RT 4-point) | 415 |

| Young’ s Modulus | Gpa (4pt bend, 1300℃) | 430 |

| Thermal Expansion (C.T.E) | 10-6K-1 | 4.5 |

| Thermal conductivity | (W/mK) | 300 |

-

factory Outlets for High Quality Extruded Graph...

-

Chinese wholesale China Lowest Friction Special...

-

Best Price on Hydrogen Fuel Cell Demonstrationt...

-

Factory making China High Quality Profiled Carb...

-

Massive Selection for 1kw 2kw 3kw 5kw Factory D...

-

Wholesale OEM/ODM China Electric Fan Motor Grap...