vet-china launches high-quality proton exchange membrane (PEM) MEA hydrogen fuel cells, which provide strong support for efficient clean energy solutions. Proton Exchange Membrane MEA Hydrogen Fuel Cell achieves excellent electrochemical performance and long service life through advanced membrane electrode assembly (MEA) technology, and is widely used in various fields from transportation to stationary power generation.

The key advantage of MEA is its excellent conductivity and low impedance, which can effectively improve the energy conversion efficiency of Proton Exchange Membrane MEA Hydrogen Fuel Cell. vet-china's innovative technology enables the components to maintain stable performance under harsh operating conditions, ensuring the efficient operation of the battery system in both high temperature and low humidity environments.

Specifications of membrane electrode assembly:

| Thickness | 50 μm. |

| Sizes | 5 cm2, 16 cm2, 25 cm2, 50 cm2 or 100 cm2 active surface areas. |

| Catalyst Loading | Anode = 0.5 mg Pt/cm2.Cathode = 0.5 mg Pt/cm2. |

| Membrane electrode assembly types | 3-layer, 5-layer, 7-layer (so before ordering, please clarify how many layers MEA you prefer, and also provide the MEA drawing). |

The main structure of fuel cell MEA:

a) Proton Exchange Membrane (PEM): a special polymer membrane in the center.

b) Catalyst Layers: on both sides of the membrane, usually composed of precious metal catalysts.

c) Gas Diffusion Layers (GDL): on the outer sides of the catalyst layers, typically made of fiber materials.

Our advantages of fuel cell MEA:

- Cutting edge technology: possessing multiple MEA patents, continuously driving breakthroughs;

- Excellent quality: strict quality control ensures the reliability of every MEA;

- Flexible customization: providing personalized MEA solutions according to customer needs;

- R&D Strength: collaborate with multiple renowned universities and research institutions to maintain technological leadership.

-

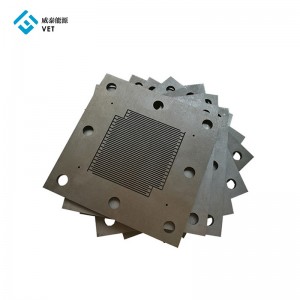

Factory Price For Graphite Bipolar Plate for Pe...

-

8 Years Exporter Aluminum Nitride Aln Ceramic P...

-

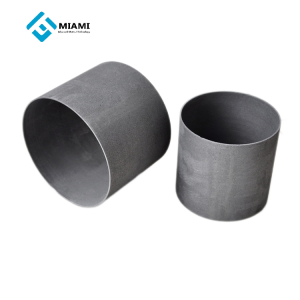

Supply OEM/ODM Self-Lubricating Isotropic Carbo...

-

Hot Selling for 0.8mm Alkaline Electrolyzer Tit...

-

Supply OEM/ODM China Continous Casting Copper G...

-

Excellent quality Electric Flexible Floor Rearv...