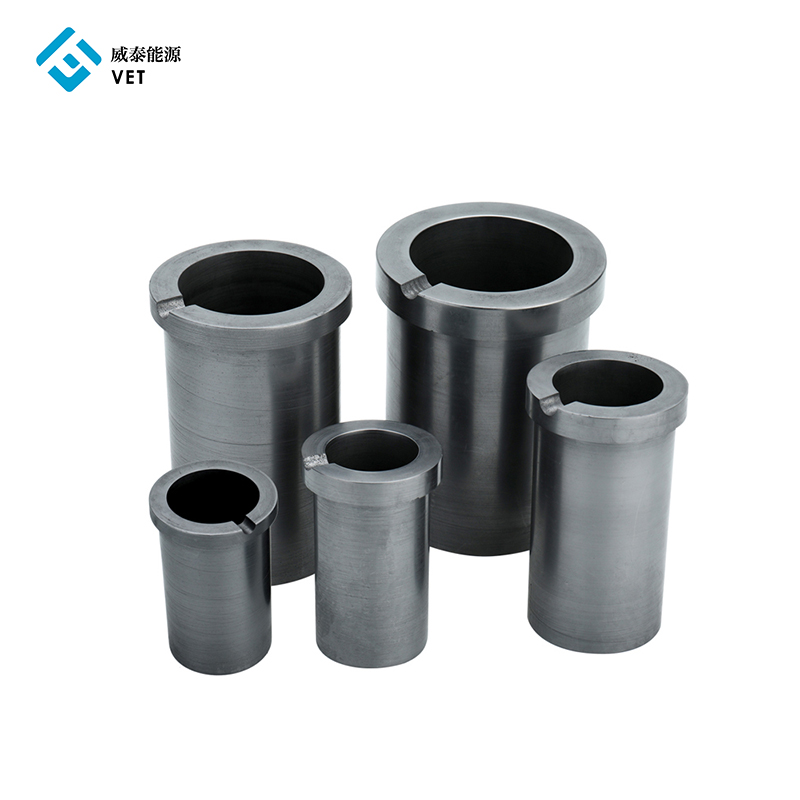

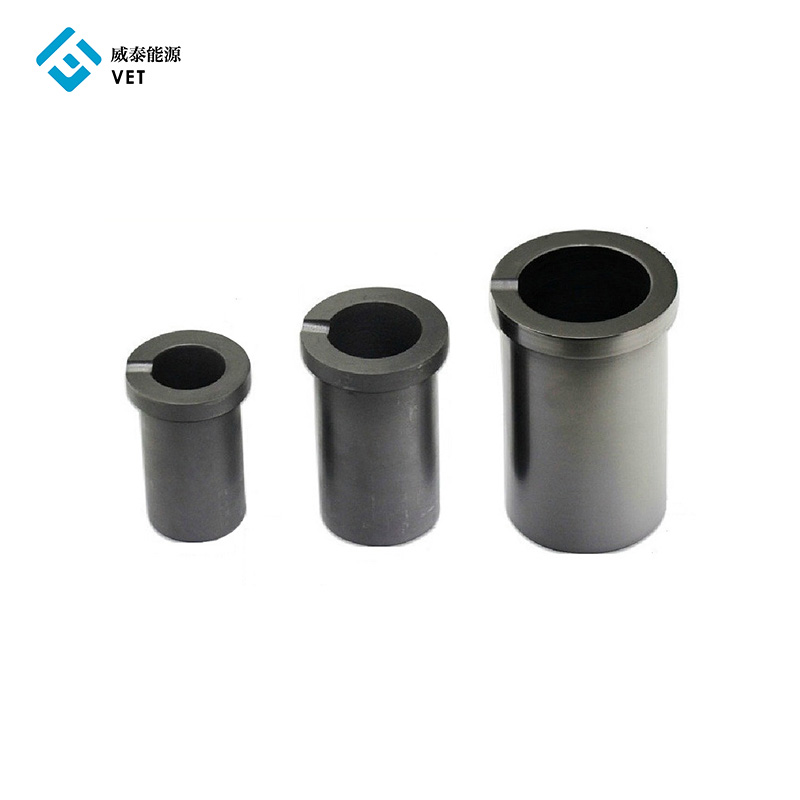

Gold Melting Graphite Crucible , Induction heating crucible for melting platinum furnace

The use of products:

1,Crucible should be placed at a dry place or placed in a wooden frame

2,The crucible tongs should be matched to the shape of crucible to avoid damage crucible

3,The quantity of the feeding should be based on the capacity of the crucible, do not feed too much or too tight, otherwise the crucible may be bursted

4,We should tap the crucible when clean the slag, in order to avoid damage the crucible body

5,The pedestal of crucible placed should put some kelp, carbon powder or asbestos powder,pedestal should be matched to the bottom of the crucible, the crucible placed in the center of furnace.

6,There should be maintained distance between crucible and furnace and the crucible should be fixed firmly by wedge

7,Using an excess oxidizer will reduce the life of the crucible.

|

Technical Data of Graphite Material |

|||||

|

Index |

Unit |

VET-4 |

VET-5 |

VET-7 |

VET-8 |

|

Bulk density |

g/cm3 |

1.78~1.82 |

1.85 |

1.85 |

1.91 |

|

Electric resistivity |

μ.Ωm |

8.5 |

8.5 |

11~13 |

11~13 |

|

Flexural Strength |

Mpa |

38 |

46 |

51 |

60 |

|

Compressive strength |

Mpa |

65 |

85 |

115 |

135 |

|

Shore Hardness |

HSD |

42 |

48 |

65 |

70 |

|

Grain size |

μm |

12~15 |

12~15 |

8~10 |

8~10 |

|

Thermal Conductivity |

W/m.k |

141 |

139 |

85 |

85 |

|

C.T.E |

10-6/°C |

5.46 |

4.75 |

5.6 |

5.85 |

|

Porosity |

% |

16 |

13 |

12 |

11 |

|

Ash Content |

PPM |

500, 50 |

500, 50 |

50 |

50 |

|

Elastic Modulus |

Gpa |

9 |

11.8 |

11 |

12 |

Ningbo VET Energy Technology Co., Ltd is a high-tech enterprise focusing on the production and sales of graphite products and silicon carbide products.We have advanced graphite processing equipment and exquisite production technology, with graphite CNC processing center, CNC milling machine, CNC lathe, large sawing machine, surface grinder and so on. We can process all kinds of difficult graphite products according to customers'requirements.

Using imported various specifications of graphite materials, we supply our domestic and overseas customers with superior quality and competitive prices.

In line with the enterprise spirit of "integrity is the foundation, innovation is the driving force, quality is the guarantee", adhering to the enterprise tenet of "solving problems for customers, creating the future for employees", and taking "promoting the development of low-carbon and energy-saving cause" as our mission, we strive to build a first-class brand in the field.

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.